A wear-resistant superhydrophobic self-cleaning composite coating and preparation method thereof

A composite coating and super-hydrophobic technology, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor wear resistance and difficult to last super-hydrophobic function, and achieve improved wear resistance, super-hydrophobic performance, and applicable wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

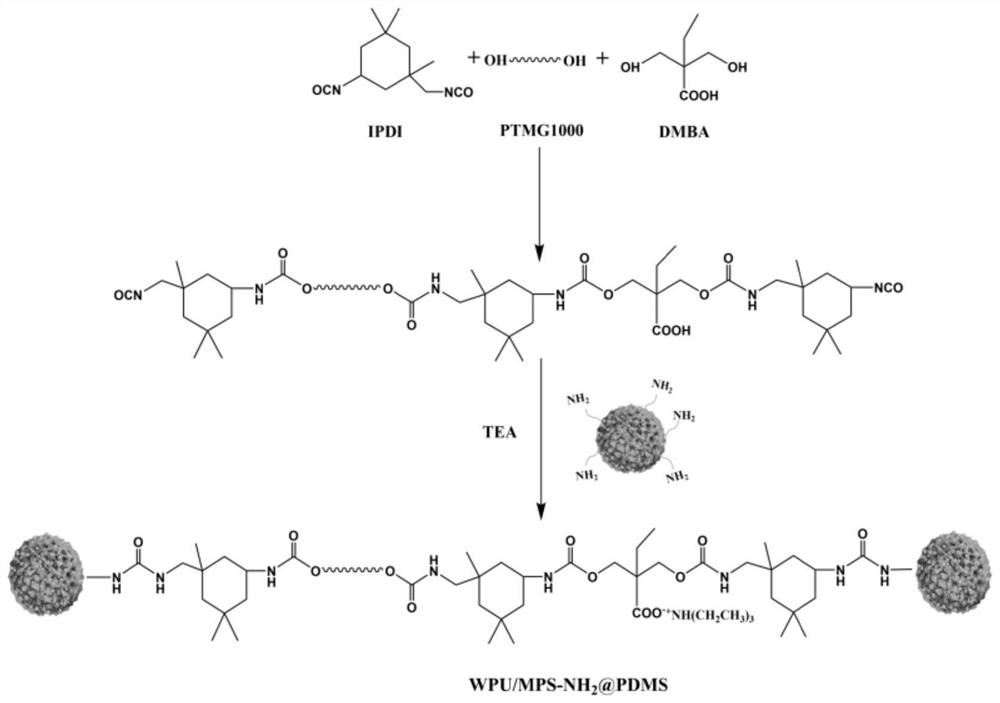

[0029] Such as figure 1 As shown, the invention discloses a method for preparing a wear-resistant superhydrophobic self-cleaning composite coating, which specifically includes the following steps:

[0030] 1)MPS-NH 2 Preparation of @PDMS composite particles

[0031] Weigh 0.1-1 part of silane coupling agent, 0.1-2 parts of deionized water and 1-20 parts of absolute ethanol, mix and stir, hydrolyze for 10-30 minutes and set aside. Then, weigh 5-60 parts of n-butanol and 1-5 parts of macroporous silicon (MPS), mix and stir, and after the MPS is completely infiltrated, sonicate for 15-30 minutes to prepare the MPS dispersion. Add the MPS dispersion into a round-bottomed flask, heat and stir at 90-100°C, and slowly add the prepared coupling agent hydrolyzate dropwise after the temperature stabilizes to react for 3-6 hours. Then, centrifuge and wash with absolute ethanol, and then vacuum-dry to obtain aminated macroporous silicon (MPS-NH 2 ). Aminated macroporous silicon (MPS-...

Embodiment 1

[0047] 1)MPS-NH 2 Preparation of @PDMS composite particles

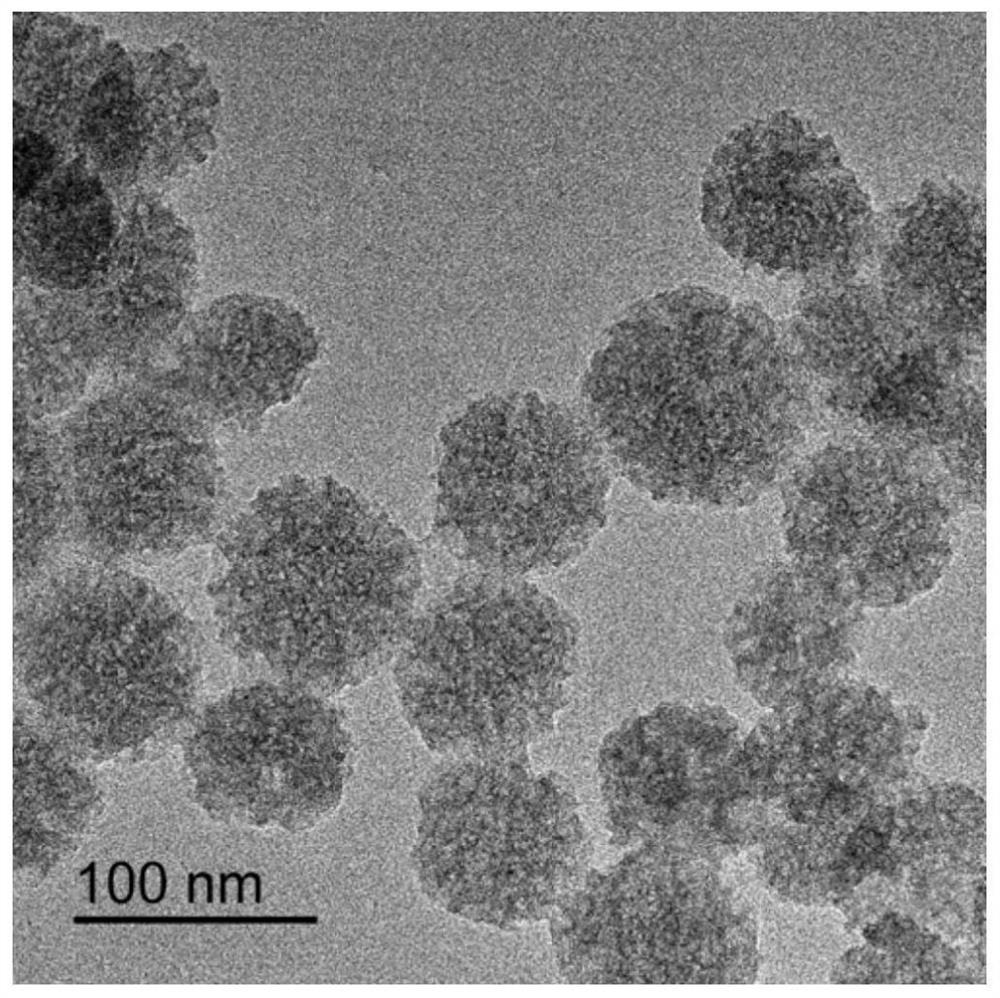

[0048] Weigh 0.1 part of KH-550 silane coupling agent, 0.1 part of deionized water and 1 part of absolute ethanol, mix and stir, hydrolyze for 10-30 minutes and set aside. Then, weigh 5 parts of n-butanol and 1 part of macroporous silicon (MPS), mix and stir, and after the MPS is completely infiltrated, sonicate for 15 minutes to prepare the MPS dispersion. Add the MPS dispersion into a round-bottomed flask, heat and stir at 90°C, and slowly add the prepared coupling agent hydrolyzate dropwise after the temperature stabilizes to react for 3 hours. Then, centrifuge and wash with absolute ethanol, and then vacuum-dry to obtain aminated macroporous silicon (MPS-NH 2 ). 1 part of aminated macroporous silicon (MPS-NH 2 ) was mixed with 40 parts of polydimethylsiloxane (PDMS), and vacuumized at 60°C for 6 hours to make PDMS completely enter MPS-NH 2 In the channel, MPS-NH 2 @PDMS composite particles.

[0049] 2)WPU / ...

Embodiment 2

[0055] 1)MPS-NH 2 Preparation of @PDMS composite particles

[0056] Weigh 1 part of KH-560 silane coupling agent, 2 parts of deionized water and 20 parts of absolute ethanol, mix and stir, hydrolyze for 30 minutes and set aside. Then, 60 parts of n-butanol and 5 parts of macroporous silicon (MPS) were weighed, mixed and stirred, and MPS dispersion liquid was prepared by ultrasonication for 30 minutes after the MPS was completely infiltrated. Add the MPS dispersion into a round-bottomed flask, heat and stir at 100°C, and slowly add the prepared coupling agent hydrolyzate dropwise after the temperature stabilizes to react for 6 hours. Then, centrifuge and wash with absolute ethanol, and then vacuum-dry to obtain aminated macroporous silicon (MPS-NH 2 ). 10 parts of aminated macroporous silicon (MPS-NH 2 ) was mixed with 300 parts of polydimethylsiloxane (PDMS), and vacuumized at 100°C for 12 hours, so that PDMS completely entered into MPS-NH 2 In the channel, MPS-NH 2 @PDM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com