Paving device for pavement water seepage test sealing material

A technology for sealing materials and laying devices, which is applied in measurement devices, analysis of suspensions and porous materials, roads, etc., can solve the problems of poor sealing effect, low efficiency, time-consuming and labor-intensive, etc., and achieves uniform thickness, ingenious structure, and good sealing quality. Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

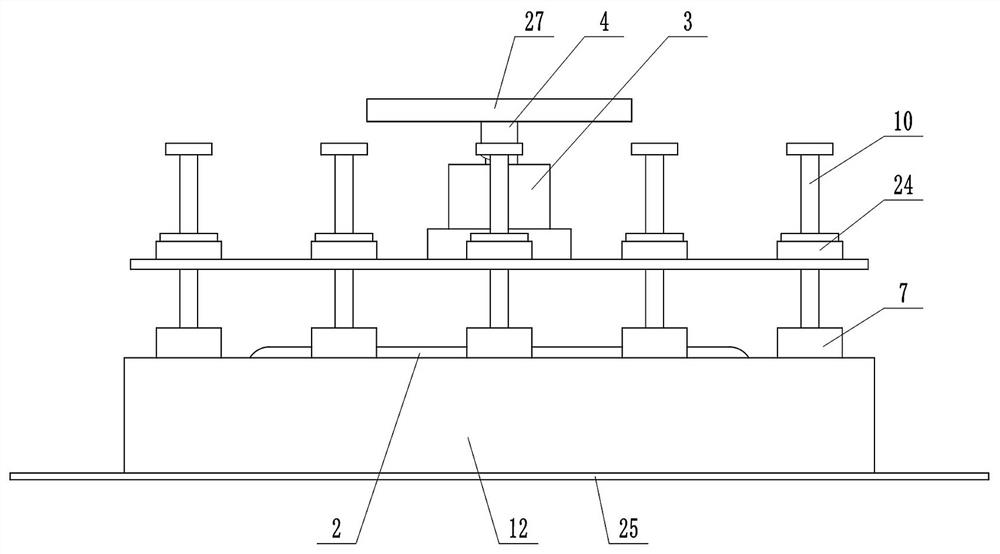

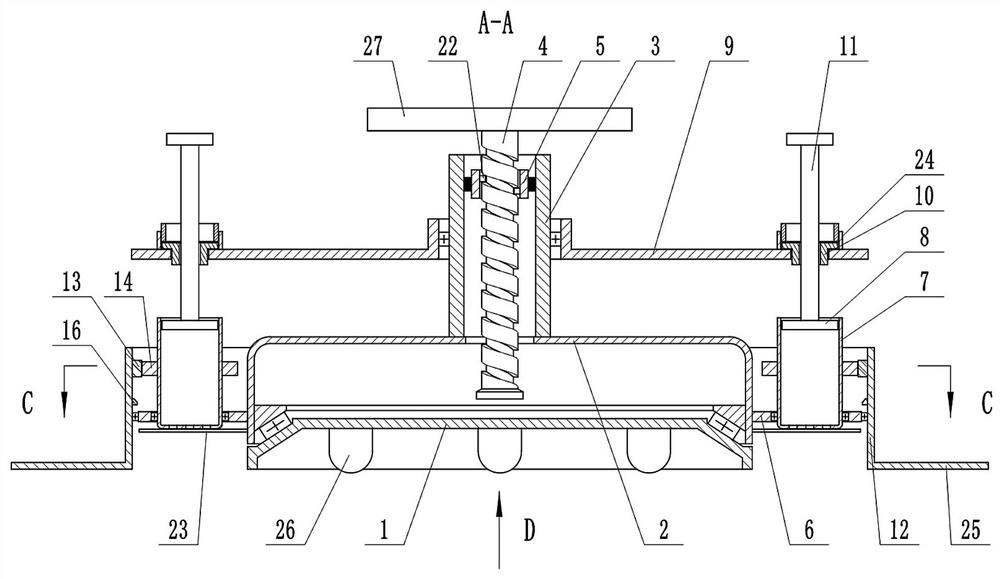

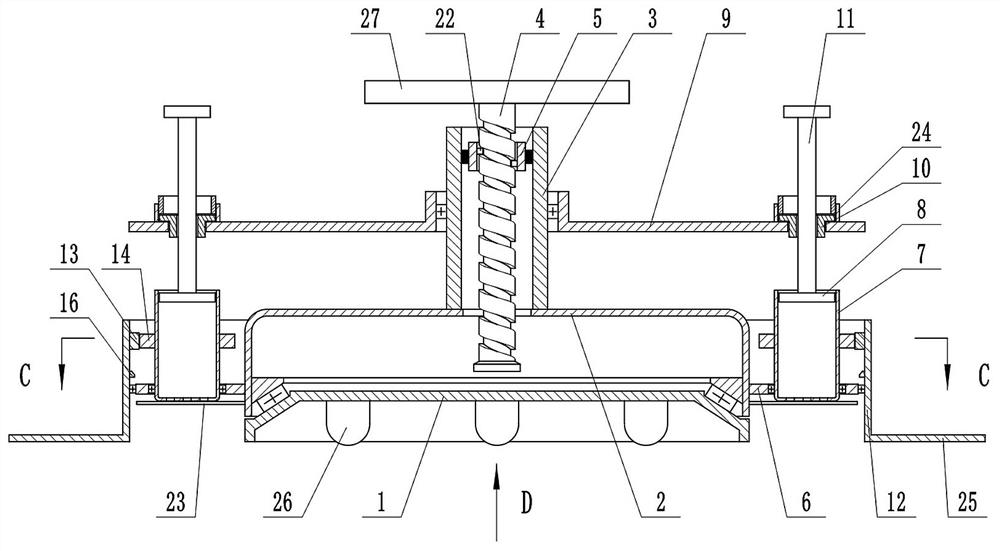

[0036] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0037] Depend on Figure 1 to Figure 11 Given, the present invention includes a base 1, the upper end of the base 1 has a rotatable inner shell 2, the upper side of the inner shell 2 is fixed with a vertical cylinder 3, and the vertical rod 4 that can move up and down is arranged in the cylinder 3, and the vertical rod 4 There is a spiral groove on the top, and a drum 5 is set on the outer side of the vertical rod 4. The vertical rod 4 moves up and down to drive the drum 5 to rotate, and a one-way clutch is installed between the drum 5 and the cylinder 3; the outer edge of the inner shell 2 An annular plate 6 is fixed on the top of the annular plate 6, and a plurality of containers 7 run through the annular plate 6. The container 7 is a cylindrical shape with an upper end opening, and a plurality of discharge ports are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com