Single-side formwork waterproof coiled material and waterproof method thereof

A technology of waterproof coiled material and single-sided formwork, which is applied to building insulation materials, roofs using flexible materials, roofing and other directions, can solve the problems of wasted coil material cost, poor flatness, etc., and improve the tensile strength and thickness difference. The effect of small, flat overlapping position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

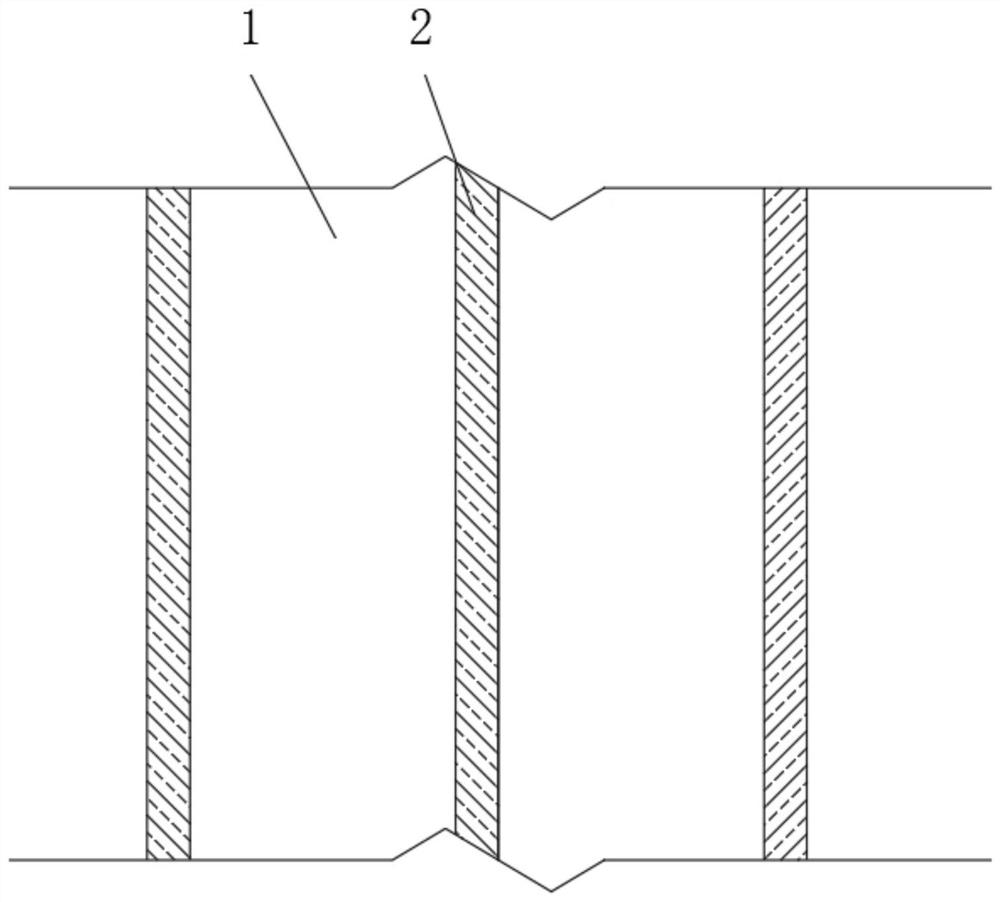

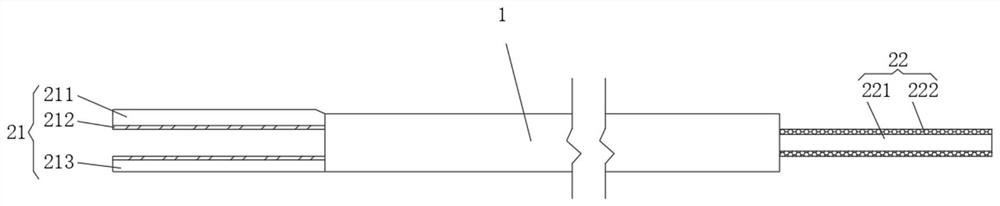

[0032] This embodiment provides a specific structure of a single-side support formwork waterproof membrane, such as Figure 1-2 As shown, it includes a coiled material body 1, and both sides of the coiled material body 1 are provided with overlapping parts 2 for overlapping two coiled material bodies 1 into one;

[0033] The overlapping part 2 includes a first overlapping body 21 and a second overlapping body 22, wherein the first overlapping body 21 can be clamped with the second overlapping body 22, and when the two coil main bodies 1 are overlapped, the second overlapping body One overlapping body 21 and the second overlapping body 22 are clamped and pasted together.

[0034] The first lapping body 21 comprises an upper lapping body 211 and a lower lapping body 213. The upper lapping body 211 is positioned above one side of the coil main body 1, and the lower lapping body 213 is positioned under the upper lapping body 211. The upper lapping body 211 and the lower lapping bo...

Embodiment 2

[0043] This embodiment provides a waterproof method for applying a waterproof membrane to a single-side formwork. The present invention also discloses a waterproof method for applying a waterproof membrane to a single-side formwork. The specific steps are as follows:

[0044] S1. Plaster and level the pile body and channel steel of the single-side formwork to form a leveling layer, and pour a cushion on the ground outside the single-side formwork;

[0045] S2, laying the waterproof membrane on the leveling layer and the cushion;

[0046] S3. Pouring a waterproof protective layer on the surface of the waterproof membrane.

[0047] The laying method of the waterproof coiled material in step (S2), concrete steps are as follows:

[0048] (S2.1), laying one of the waterproof rolls on the leveling layer and the cushion, when continuing to lay the next waterproof roll, the upper surface of the lower body 213 in the first roll main body 1 Apply glue to form a glued layer 212, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com