Mechanical connection inner steel bar joint spacing monitoring device and operation method

A technology of mechanical connection and monitoring device, which is applied in the direction of measuring device, electrical device, instrument, etc., can solve problems such as improper construction of steel bar joints, improper operation of workers, economic losses, quality problems, etc., to achieve excellent practicability, unique principle, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Embodiment (taking the resistance signal as an example)

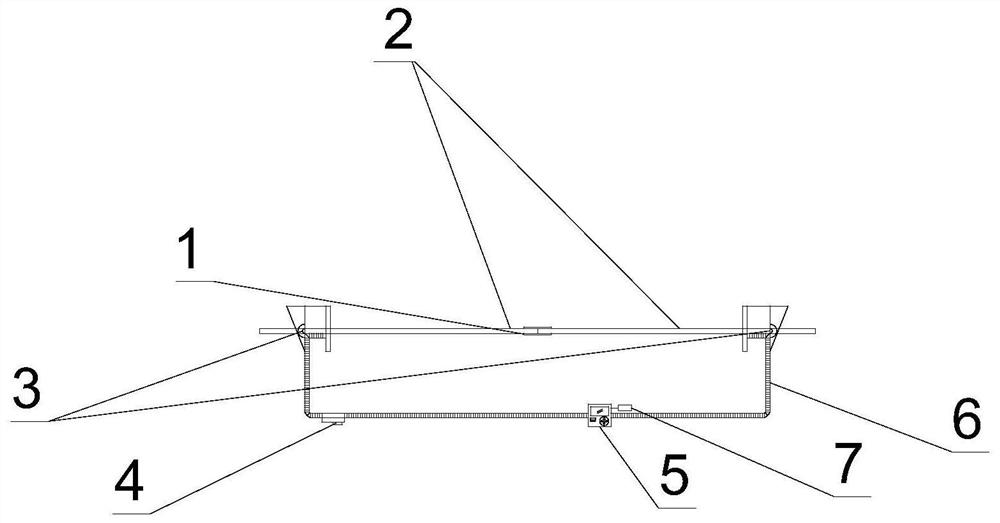

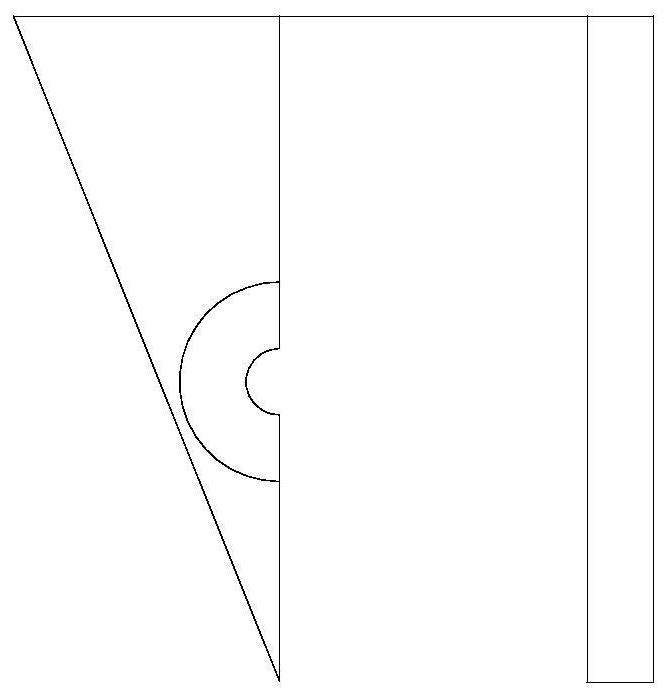

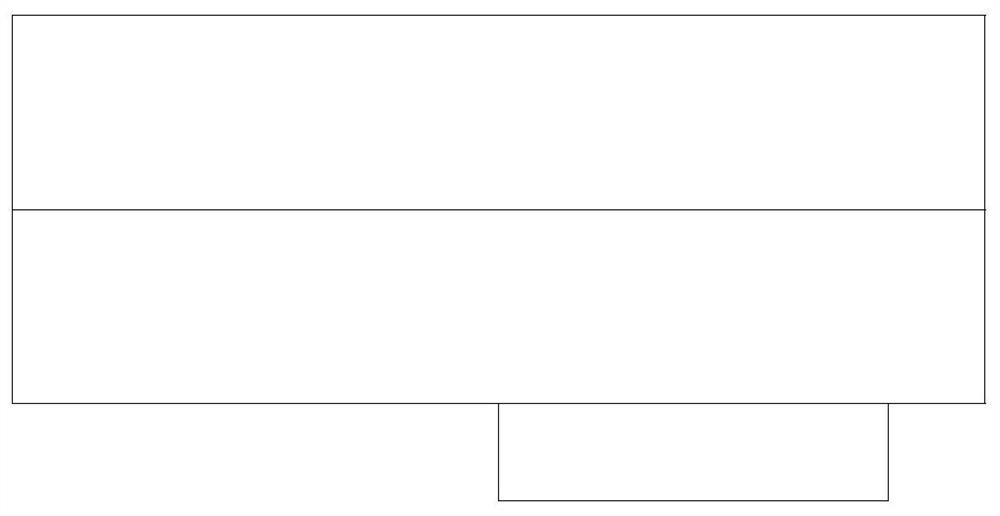

[0033] Such as Figure 1 to Figure 4 As shown, the specific embodiment is: a mechanically connected internal steel bar joint spacing monitoring device, including a signal sensor module 3, a signal sensing module 4, a wire 6, a mobile power supply 7 and a monitoring display 5, and the signal sensor module 3 is provided with two One and respectively movably installed on the two outer steel bars of the mechanical connector, the signal sensor is connected with the signal sensing module 4, mobile power supply 7 and monitoring display 5 through the wire 6 and cooperates with the mechanical connector to form a closed loop.

[0034] Wherein, the signal sensor module 3 collects the resistance signal through the area between the two signal sensor modules 3, and the collected resistance can be obtained according to the formula R=ρL / S, (ρ represents the resistivity of the butt steel bar 2, and L represents that electrons pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com