Turbine blade wear monitoring method based on historical data

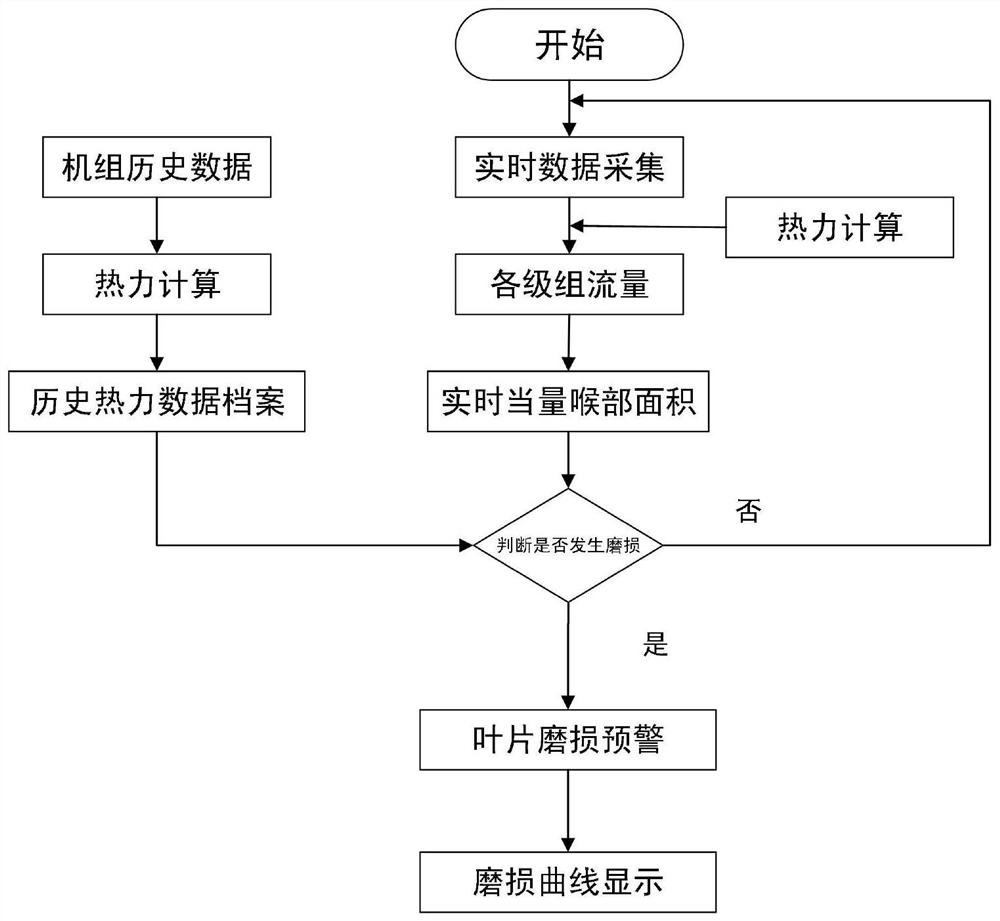

A steam turbine blade and historical data technology, which is applied in the testing of mechanical components, electrical digital data processing, special data processing applications, etc., can solve problems such as efficiency decline, blade damage, and the inability to monitor blade wear accurately and in real time The results are reasonable and accurate, the fault prediction is realized, and the method is simple and effective.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Based on the performance assessment test data of a certain unit, historical data files were established. Among them, the equivalent throat area from the medium-pressure cylinder to the third-stage extraction is 4331.8. After a period of operation, the equivalent throat area tends to increase. Based on operating data such as pressure and temperature, the equivalent throat area at a certain moment is calculated to be 4474.7, and the change rate of the equivalent throat area reaches 3.3%. It is judged that the blades of the flow part of the unit are eroded and worn.

[0036] After the stage group was shut down and the cylinder was removed for inspection, it was found that the first-stage vane of the medium pressure cylinder was eroded by particles, resulting in wear and tear, resulting in an increase in the flow area of the stage group, which was the same as the calculation and judgment result.

[0037] The invention can monitor the degree of wear of the steam turbine bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com