Engineering sampling device for building supervision

A sampling device and supervision technology, applied in the direction of sampling devices, etc., can solve the problems of time-consuming and labor-intensive manual sampling, the influence of test results, and the inability to quickly know the quality of samples, so as to increase accuracy and save manpower and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

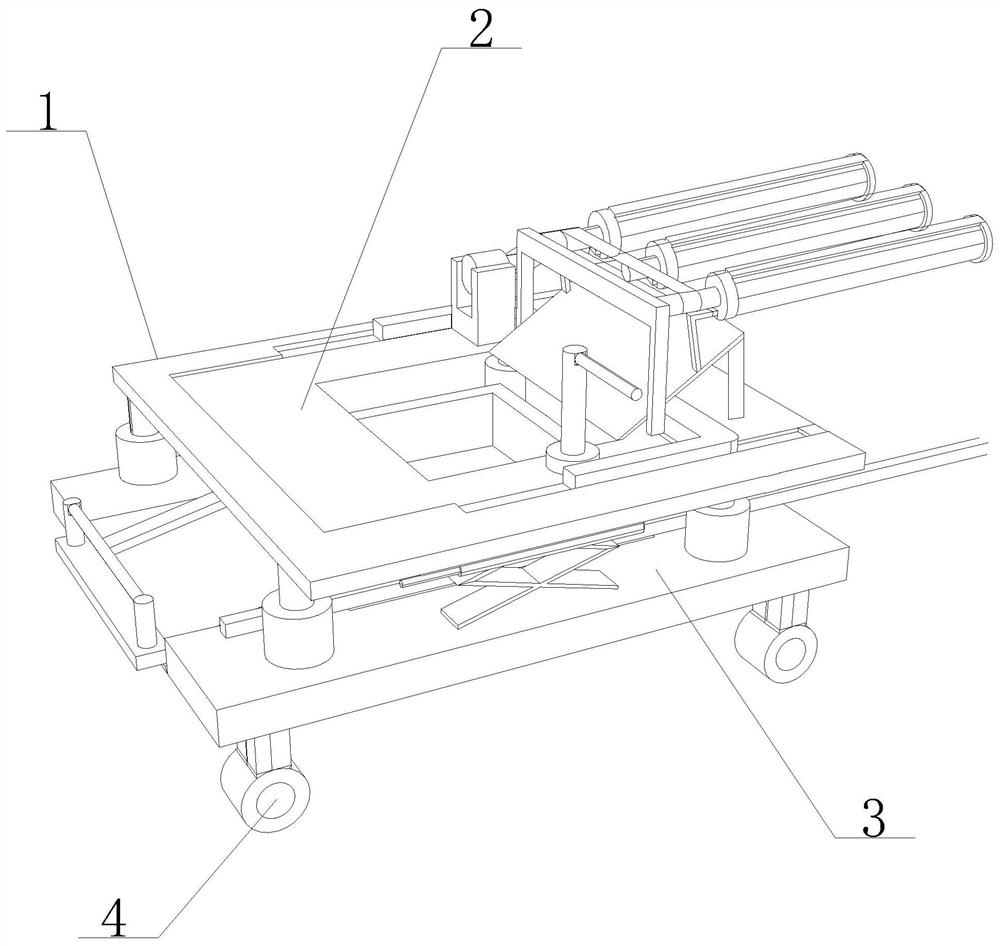

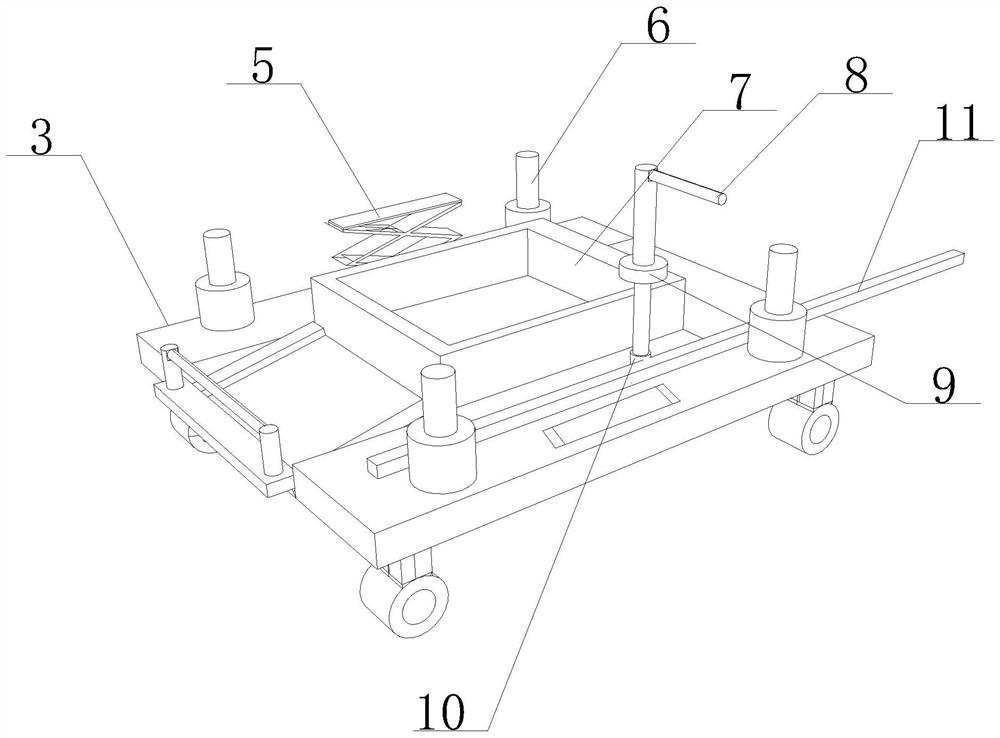

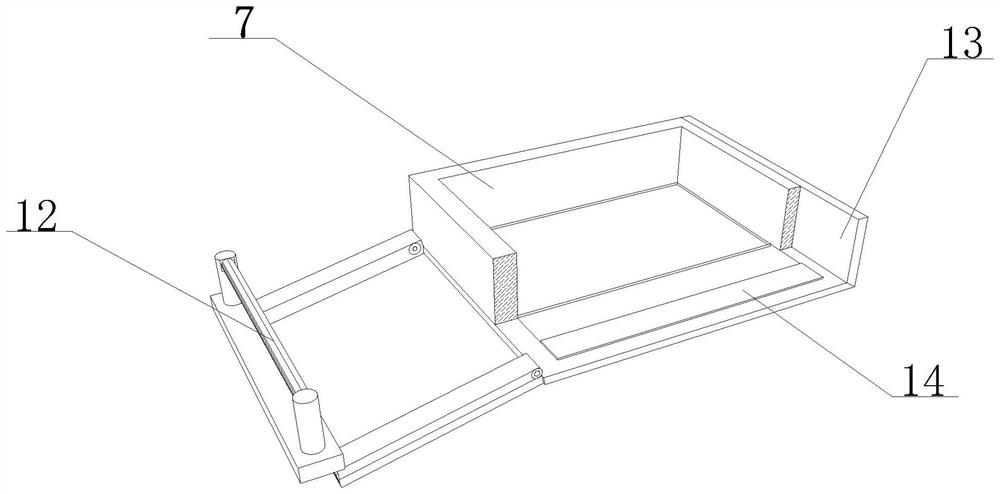

[0037] Such as Figure 1-6 As shown, the present invention provides a kind of engineering sampling device for construction supervision, comprising a main body device 1, an upper-level device 2 and a lower-level device 3, the main body device 1 is provided with an upper-level device 2 and a lower-level device 3, and the upper surface of the upper-level device 2 is opened There is a material receiving port 17, and the setting of the material receiving port 17 is to collect samples quickly and conveniently. Both sides of the upper surface of the upper device 2 are provided with sliding grooves 16, and the surface of the sliding groove 16 is movably connected with a sliding bracket 23. The setting of the sliding groove 16 In order to facilitate the sliding support 23, the outer side of the upper end of the sliding support 23 is movably connected with a sand-taking rotating shaft 19, and one side of the sliding support 23 is fixedly connected with a drive motor 18, and the driving m...

Embodiment 2

[0042] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the bottom surface of the lower device 3 is fixedly connected with universal wheels 4, and the setting of universal wheels 4 is to facilitate the equipment in the complex environment of the construction site. The bottom is more convenient to transfer, saving time and effort. The upper surface of the lower device 3 is fixedly connected with elastic devices 5. The elastic device 5 is set to buffer the pressure of the upper device 2 on the lower device 3 when it is in use. The lower device 3 An elevating device 6 is fixedly connected to the outside of the upper surface, and the elevating device 6 is provided to adjust the overall height of the upper device 2, thereby adjusting the samples taken by the sand-taking cylinder 20 at different positions.

[0043] In this embodiment, the elastic device 5 and the elevating device 6 are important devices for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com