Test fixture for fuel cell membrane electrode

A fuel cell membrane and test fixture technology, which is applied to parts and circuits of fuel cells and electrical measuring instruments, can solve the problems of difficulty in quickly understanding the performance of single cell membrane electrodes, and inability to monitor the stress state of membrane electrodes in real time. Helps to design, test the effect of accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

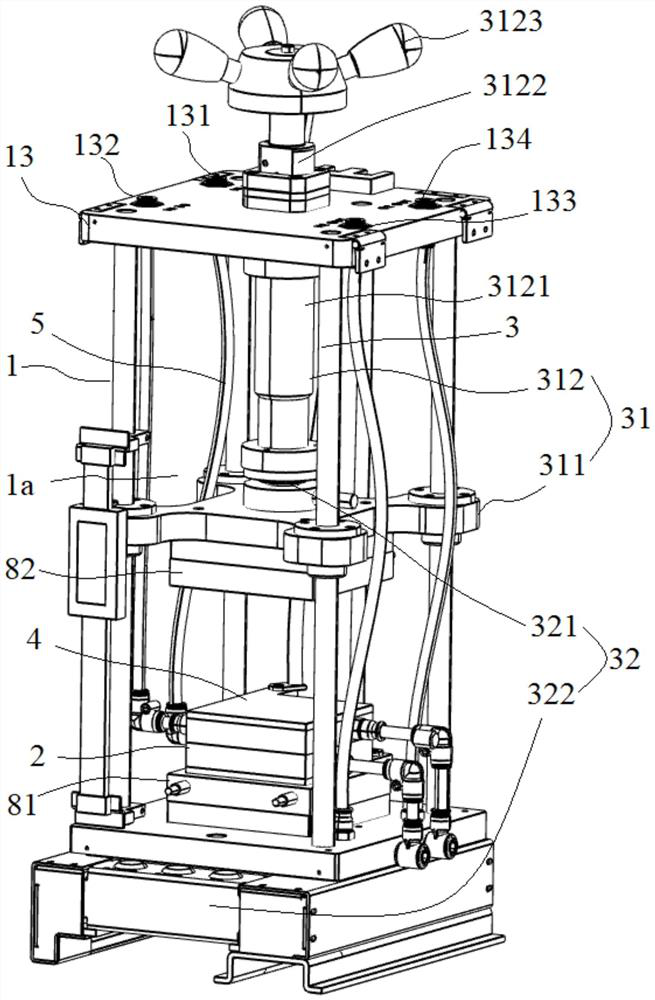

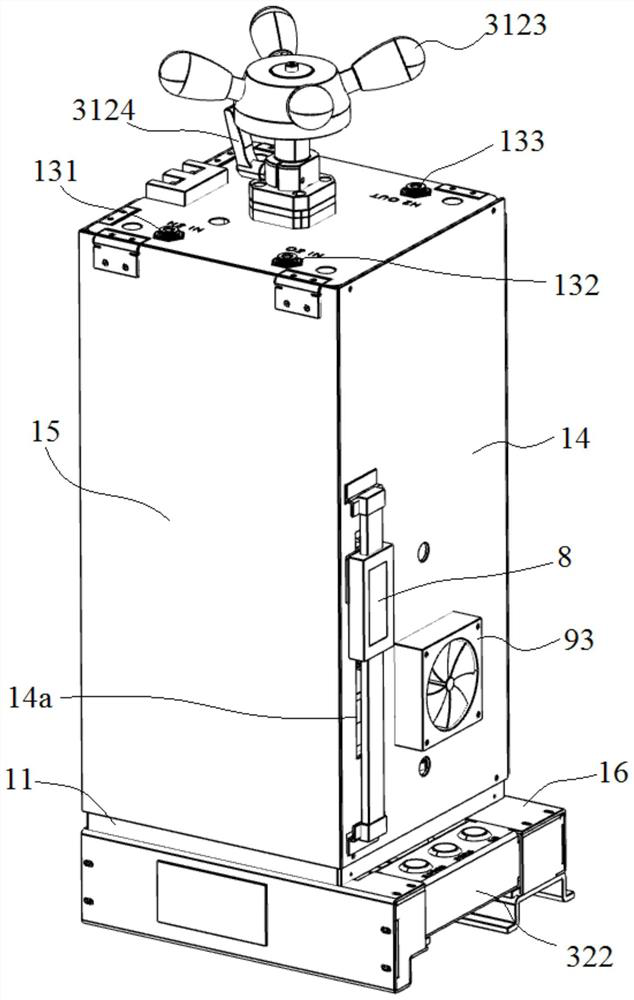

[0034] Such as figure 1 As shown, the embodiment of the present invention provides a fuel cell membrane electrode test fixture, including a frame 1 , a single cell assembly 2 , a pressing assembly 3 , a detection assembly 4 and a gas delivery assembly 5 .

[0035] The frame 1 has an accommodating cavity 1a inside, and the bottom of the accommodating cavity 1a is horizontal.

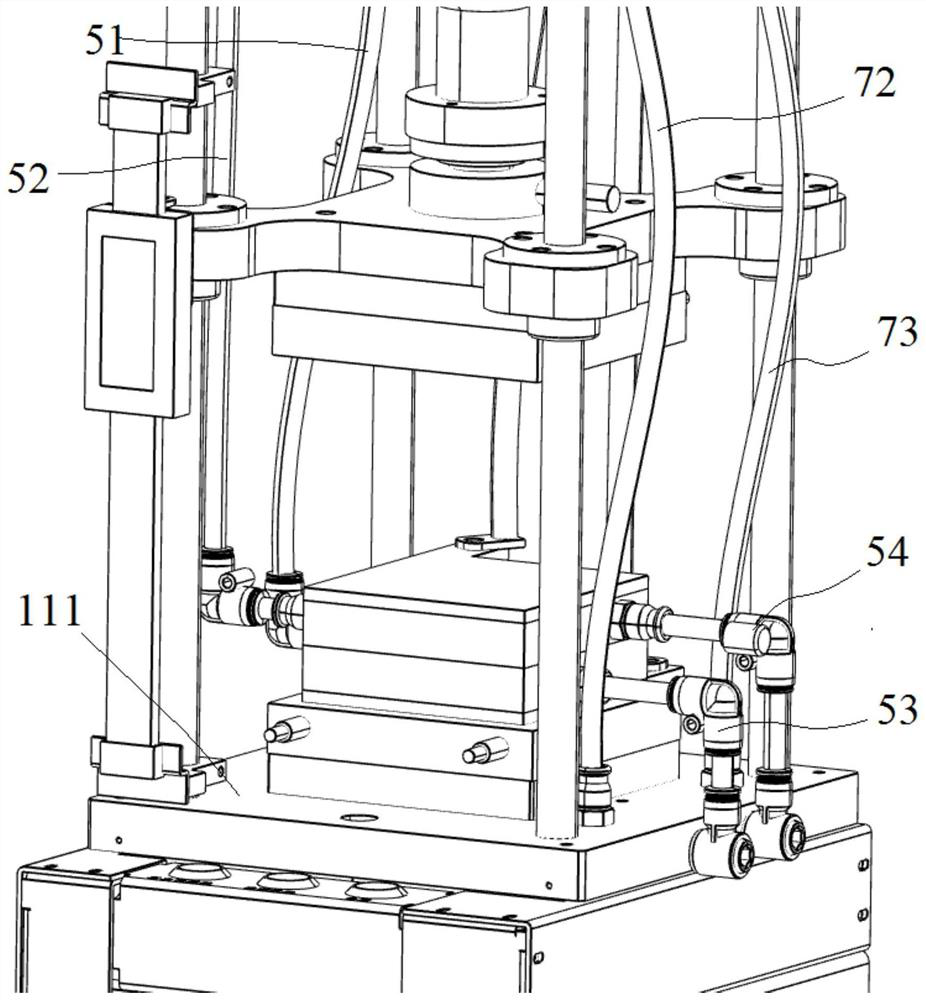

[0036] Specifically, combine image 3 As shown, the frame 1 includes a base plate 11, a guide column 12 and a top plate 13, the upper end of the base plate 11 has a horizontally arranged bearing surface 111, the guide c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com