Instrument measuring point installation intelligent design method and system, equipment and storage medium

A design method and measuring point technology, applied in the field of instrument measuring point installation, can solve problems such as no measuring point positioning, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

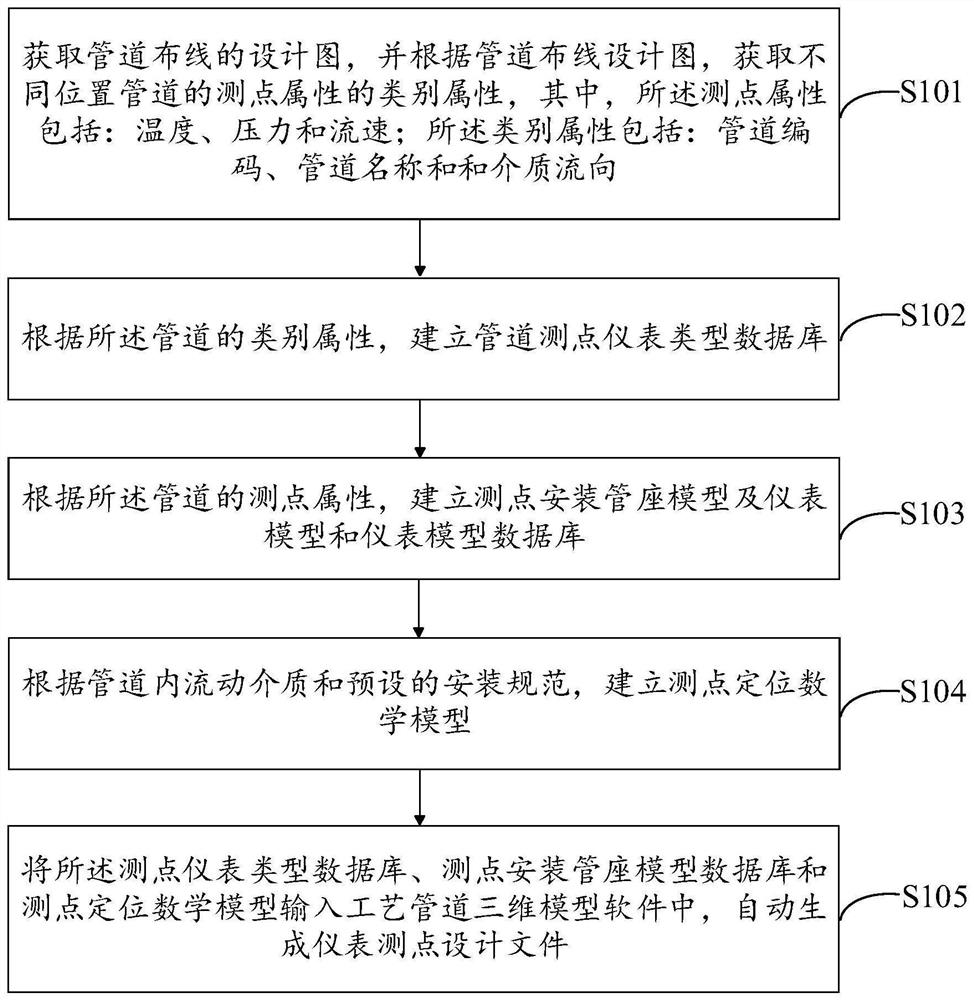

[0045] Such as figure 1 As shown, a kind of instrument measuring point installation intelligent design method of the present invention, at least comprises the following steps:

[0046] S101. Obtain the design drawing of the pipeline routing, and according to the pipeline routing design drawing, obtain the category attributes of the measuring point attributes of the pipelines at different positions, wherein the measuring point attributes include: temperature, pressure and flow rate; the category attributes include: pipeline code and the pipe name;

[0047] Specifically, by obtaining the design drawing of the pipeline wiring on the construction site, the category attributes of the measuring point attributes of the pipelines in different positions are obtained, wherein the measuring point attributes include: temperature, pressure and flow velocity; the category attributes include: pipeline code and pipeline name and medium flow direction;

[0048] S102. According to the categor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com