Sound control ink jet printing method and system for improving printing homogenenous degree

An inkjet printing and acoustic wave technology is applied in the field of acoustic wave power output of a power level control system, which can solve problems such as system unevenness, influence on operation uniformity, and adverse effect on operation uniformity, and achieve the effect of reducing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

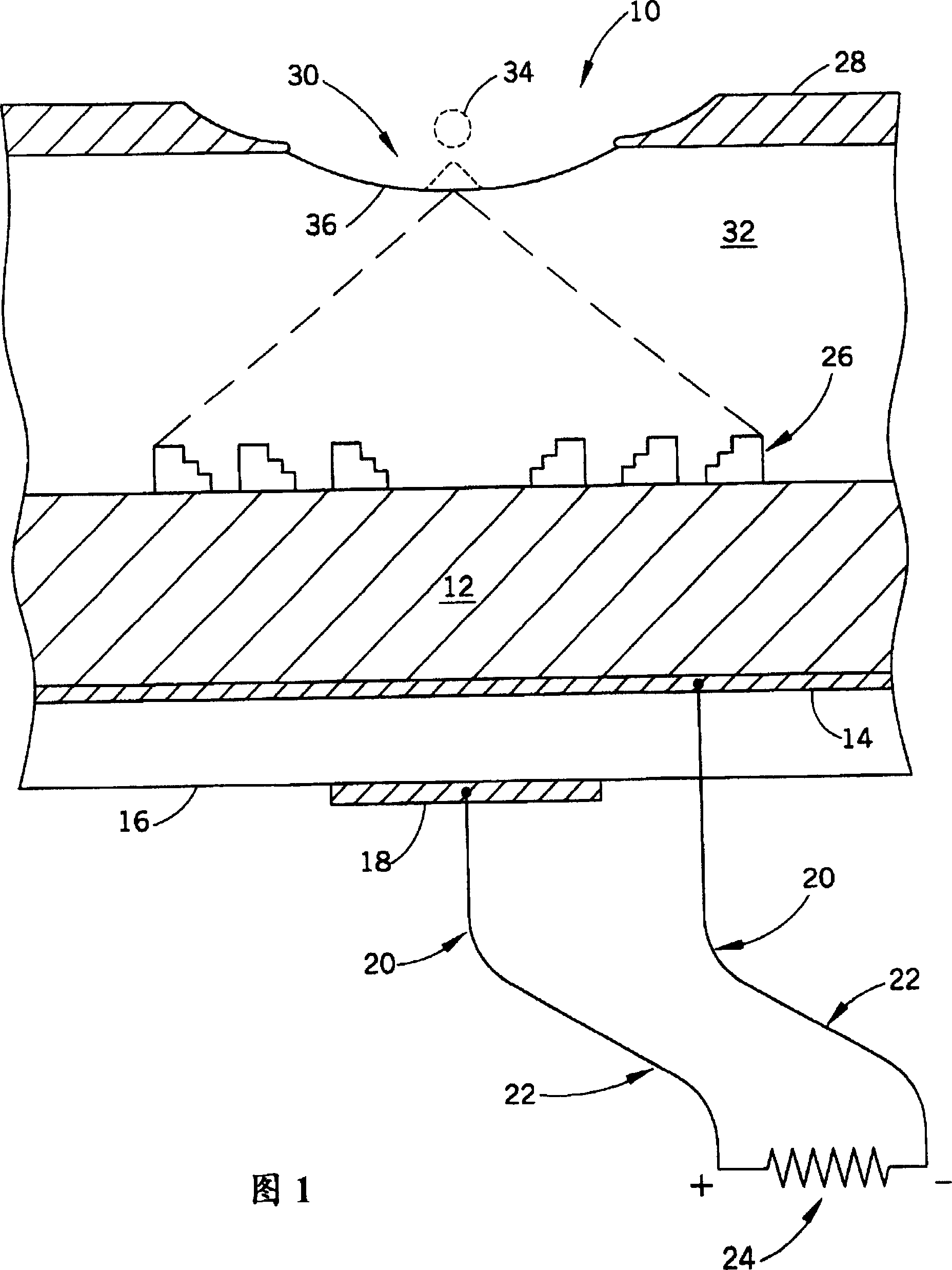

[0025] Referring to the accompanying drawings below, the accompanying drawings are only used to illustrate preferred embodiments of the present invention, and are not intended to limit the present invention. FIG. 1 is a view of an exemplary voice-activated inkjet printing element 10 applicable to the present invention. Of course, other structures may also be applicable to the present invention.

[0026] As shown, element 10 includes a glass layer 12 overlaid with an electrode layer 14 . A piezoelectric layer 16 is preferably formed of zinc oxide and disposed on electrode layer 14 , and electrodes 18 are disposed on piezoelectric layer 16 . Electrode layer 14 and electrodes 18 are connected by a surface wiring pattern schematically indicated at 20 and cables 22 to an RF power source 24 which generates power to the electrodes 14 and 18 . On the opposite side of the electrode layer 14 is a lens preferably formed by a concentric Fresnel lens. Spaced from the lens 26 is a level c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com