Sandwich biscuit containing coarse cereals and production process thereof

A sandwich biscuit and production process technology, which is applied in the field of sandwich biscuit processing, can solve problems such as the reduction of the contact surface between the sandwich layer and the biscuit layer, cracking of biscuits, overflow of the sandwich layer, etc., and achieve the effects of preventing overflow, improving the contact surface, and improving the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

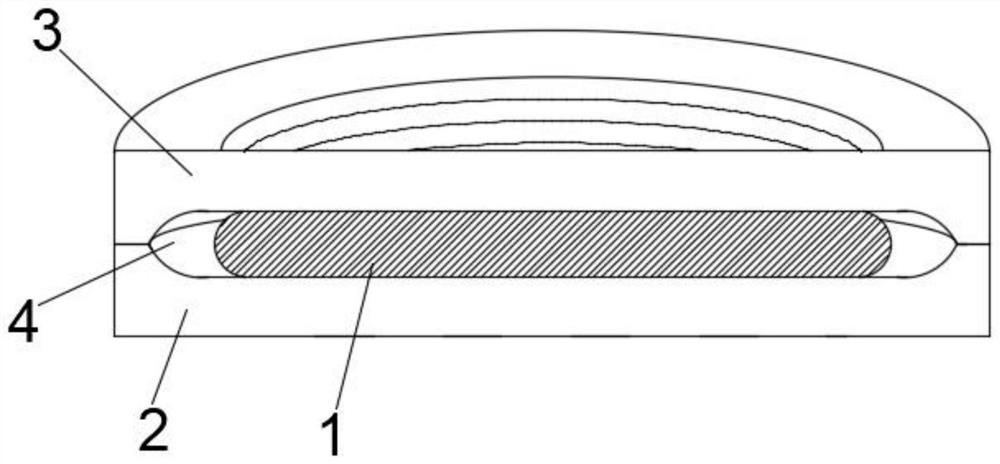

[0040] Such as figure 1 As shown, the depth of the arc-shaped groove 4 is half of the thickness of the lower biscuit sheet 2 and the upper biscuit sheet 3, and the lower biscuit sheet 2 and the upper biscuit sheet 3 are bonded and fixed by the sandwich layer 1. The setting of 4 enables the lower biscuit sheet 2 and the upper biscuit sheet 3 to wrap the sandwich layer 1 well, avoiding the loss of the sandwich layer 1 while improving the mouthfeel of the sandwich biscuit containing miscellaneous grains when chewed.

Embodiment 2

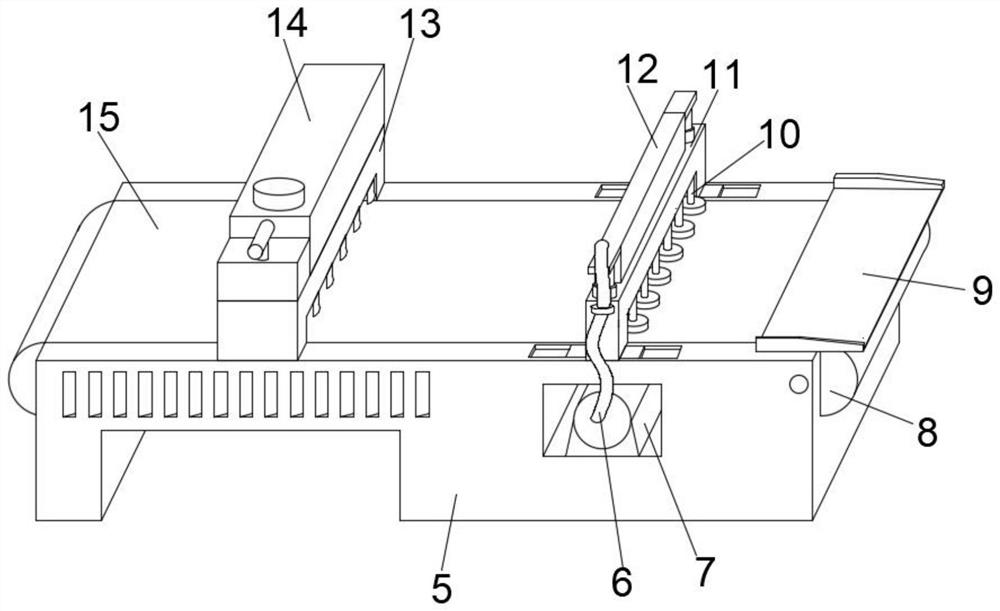

[0042] Such as Figure 2-4 As shown, the driving drum 8 is driven by a motor, so that the driving drum 8 drives the conveyor belt 15 to move, and the lower biscuit sheet 2 and the upper biscuit sheet 3 are conveyed.

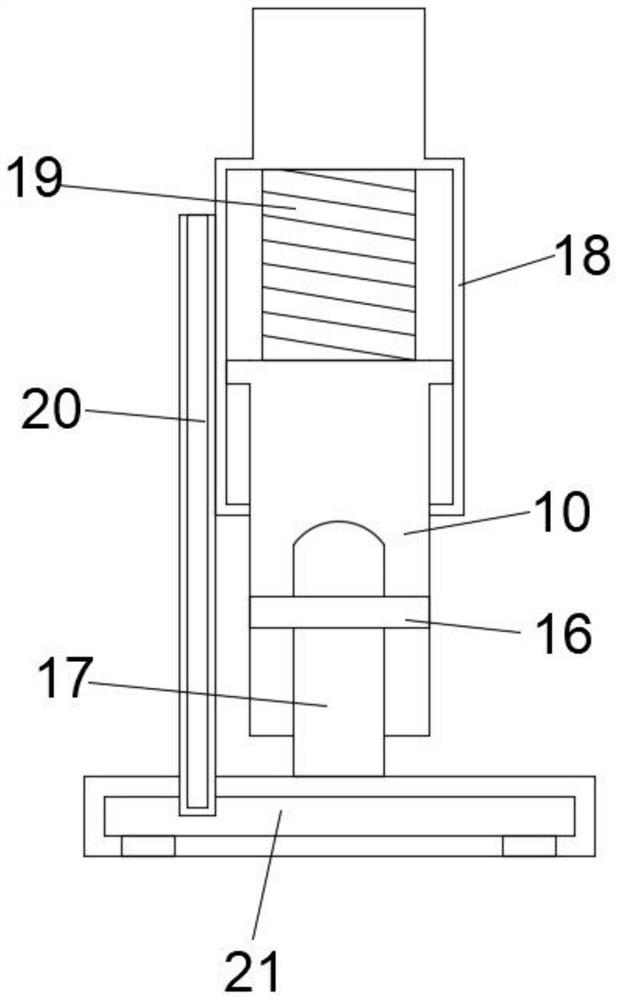

[0043] The lifting cover 12 is driven down by the hydraulic rod, and the upper biscuit sheet 3 is adsorbed and fixed by the electric sucker 21. The lifting cover 12 cooperates with the lifting rod 10 to drive the electric sucker 21 to move upward, so that the upper biscuit sheet 3 is lifted upward, so that the upper biscuit sheet 3 It can be pressed on the top of the lower biscuit sheet 2.

[0044] Drive the lower biscuit sheet 2 to move through the conveyor belt 15, move the lower biscuit sheet 2 directly below the upper biscuit sheet 3, and control the position between the upper biscuit sheet 3 and the lower biscuit sheet 2, which can effectively avoid the lower biscuit sheet 2 and the upper biscuit sheet. 3. Misalignment occurs during pressing to improve the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap