Self-tapping dental implant

A technology of dental implants and bases, which can be used in dentistry, dental implants, dental restorations, etc., and can solve problems such as time-consuming healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

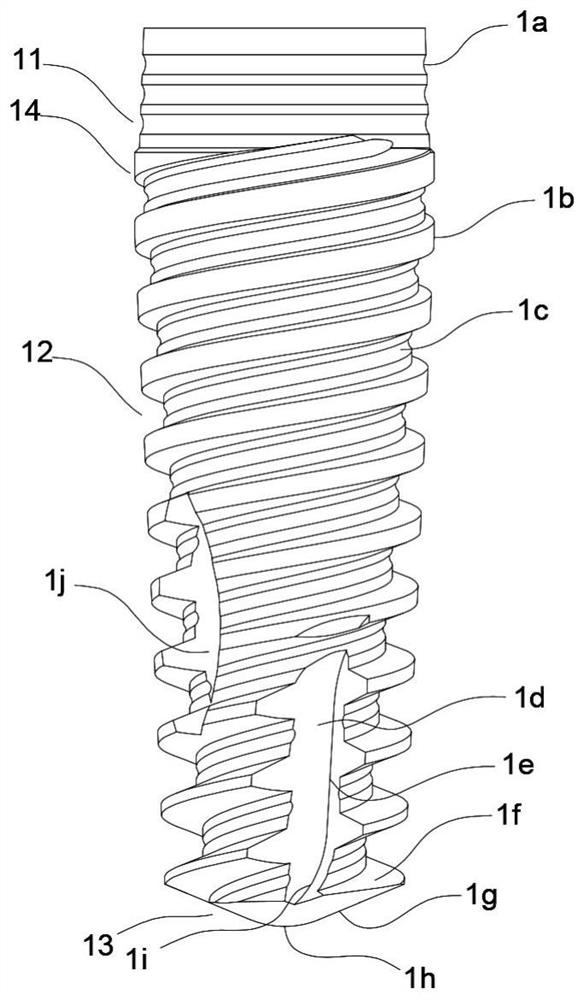

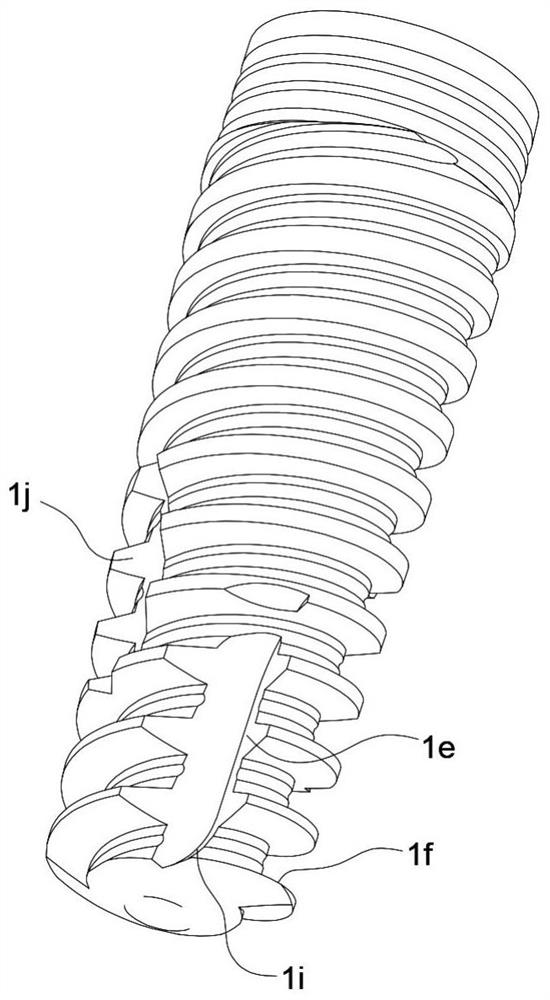

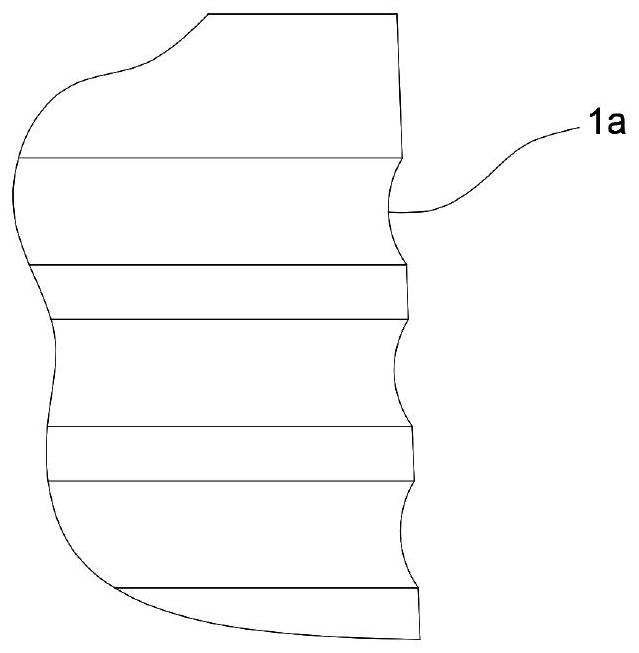

[0045] Such as Figure 1-Figure 9 As shown, a self-tapping dental implant includes an implant base 1, and the implant base 1 includes a head 11, a main body 12 and a tail 13 connected sequentially from top to bottom, and the main body is thick at the top and thin at the bottom. The outer surface of the main body is provided with external threads 1b, the middle part of the main body is provided with at least one middle cutting groove 1j, and the lower part of the main body is provided with at least one tail cutting groove 1d .

[0046] The trailing cutting groove 1d includes a straight edge 1e on a plane parallel to the central axis of the implant base and an inclined edge 1i inclined to the central axis of the implant base. The oblique edge and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com