Sensor tin soldering equipment capable of automatically and accurately positioning optical filter

A technology of precise positioning and optical filters, applied in the field of sensors, can solve the problems of sensor parts being damaged and difficult to change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

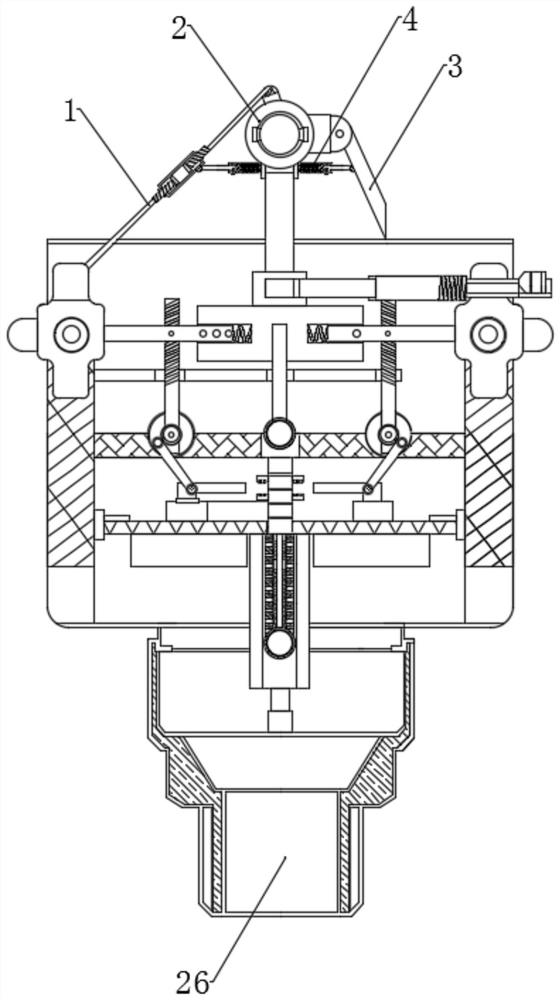

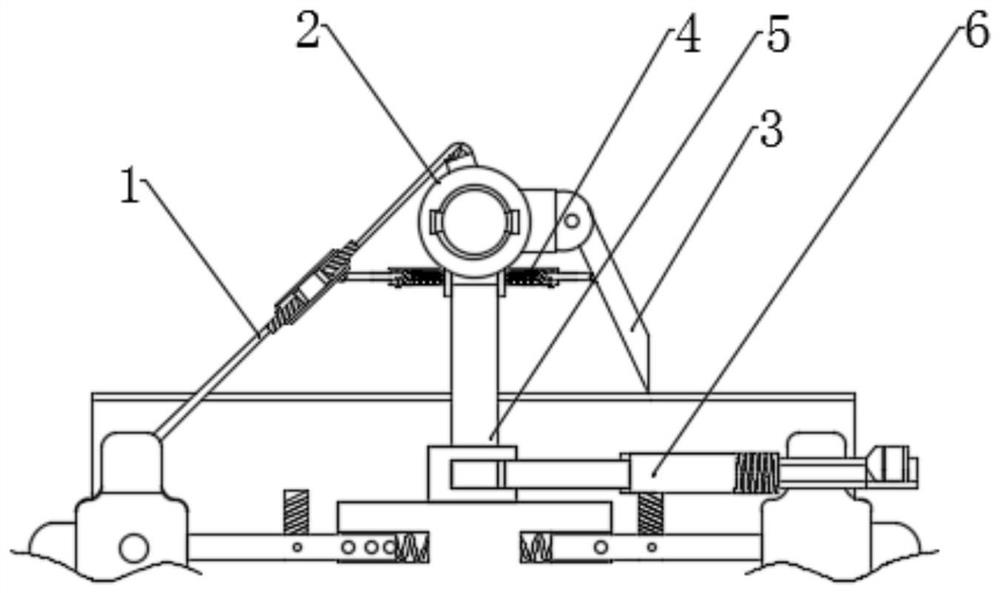

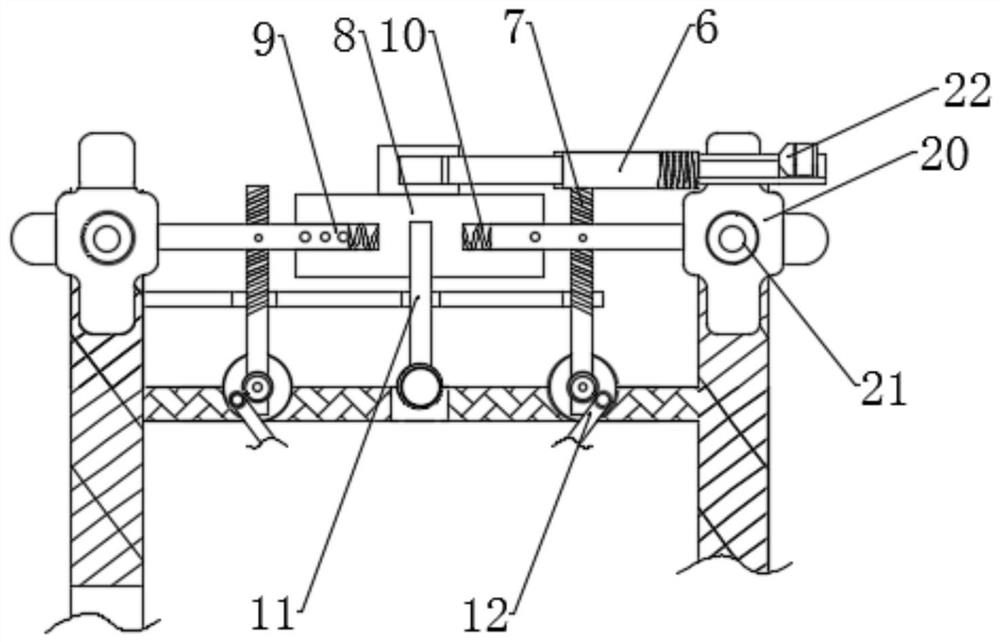

[0027] see Figure 2-Figure 4 , a sensor soldering equipment for automatic and precise positioning of optical filters, comprising a main body 1, a metal frame 2, a solder tube 3 is movably connected to the right end of the metal frame 2, and a pulling member 4 is movably installed between the solder tube 3 and the metal frame 2, and the pulling A support rod 5 is movable installed at the center of the part 4, and the right end of the support rod 5 is sleeved with a fastening seat 6, and the bottom end of the fastening seat 6 is movably connected with a central rod 7, and the middle of the central rod 7 is fixedly connected to the filter at the bottom of the support rod 5. The left and right sides of the optical sheet 8 and the optical filter 8 and the lower end of the fastening seat 6 are movably connected with an active rod 9 .

[0028] Further, the pulling member 4 includes a buffer spring 10, the bottom end of the optical filter 8 is fixedly installed with a strut 11 in the...

Embodiment 2

[0032] see Figure 4 , a sensor soldering equipment for automatic and precise positioning of optical filters, comprising a main body 1, a metal frame 2, a solder tube 3 is movably connected to the right end of the metal frame 2, and a pulling member 4 is movably installed between the solder tube 3 and the metal frame 2, and the pulling A support rod 5 is movable installed at the center of the part 4, and the right end of the support rod 5 is sleeved with a fastening seat 6, and the bottom end of the fastening seat 6 is movably connected with a central rod 7, and the middle of the central rod 7 is fixedly connected to the filter at the bottom of the support rod 5. The left and right sides of the optical sheet 8 and the optical filter 8 and the lower end of the fastening seat 6 are movably connected with an active rod 9 .

[0033] Further, it also includes a base plate 13, the bottom end of the swing bar 12 is fixedly connected with a plug-in bar 14, the rear end of the plug-in ...

Embodiment 3

[0038] see Figure 1-5 :

[0039] A sensor soldering equipment for automatic and precise positioning of optical filters, comprising a main body 1, a metal frame 2, a solder tube 3 is movably connected to the right end of the metal frame 2, and a pulling part 4 is movably installed between the solder tube 3 and the metal frame 2, and the pulling part 4. A support rod 5 is movably installed in the center, and the right end of the support rod 5 is sleeved with a fastening seat 6. The bottom end of the fastening seat 6 is movably connected with a central rod 7. The middle of the central rod 7 is fixedly connected to the filter at the bottom of the support rod 5. 8, the left and right sides of the filter 8 and the lower end of the fastening seat 6 are movably connected with an action rod 9.

[0040] Further, the pulling member 4 includes a buffer spring 10, the bottom end of the optical filter 8 is fixedly installed with a strut 11 in the middle of the action rod 9, and the left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com