Decorative aluminum plate producing, manufacturing and cutting machining machine and machining method

A technology for cutting and processing aluminum plates, which is applied in the field of cutting and processing machinery and processing for the production and manufacture of decorative aluminum plates, and can solve the problems of inability to cut decorative aluminum plates, reduce the accuracy of decorative aluminum plates, and affect the cutting effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

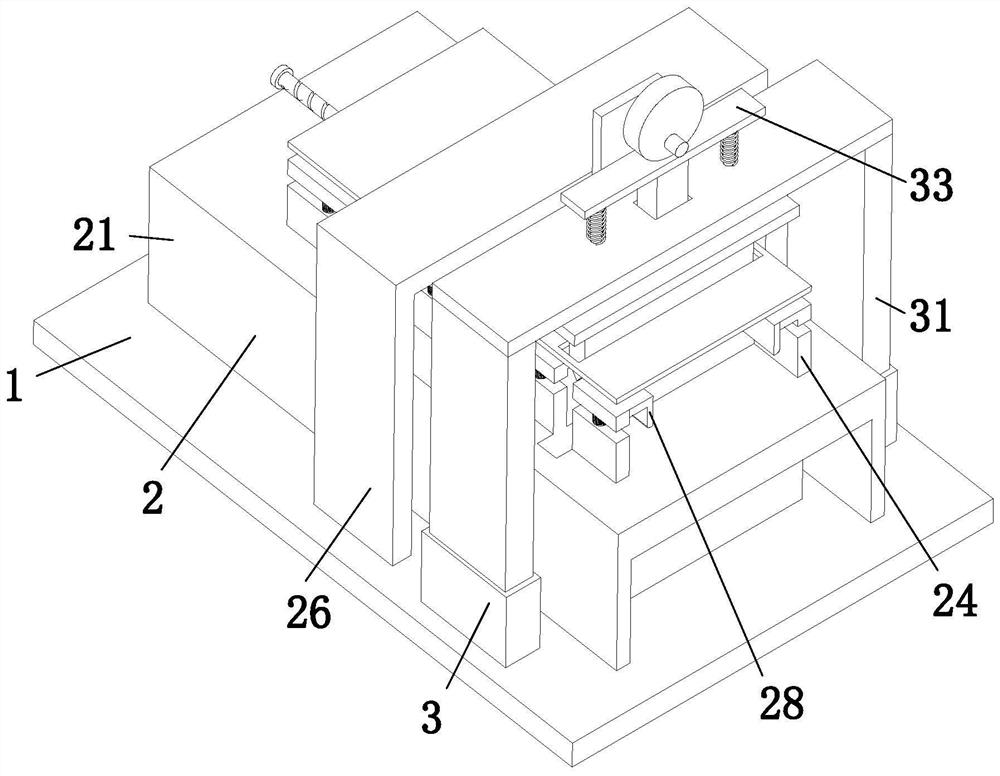

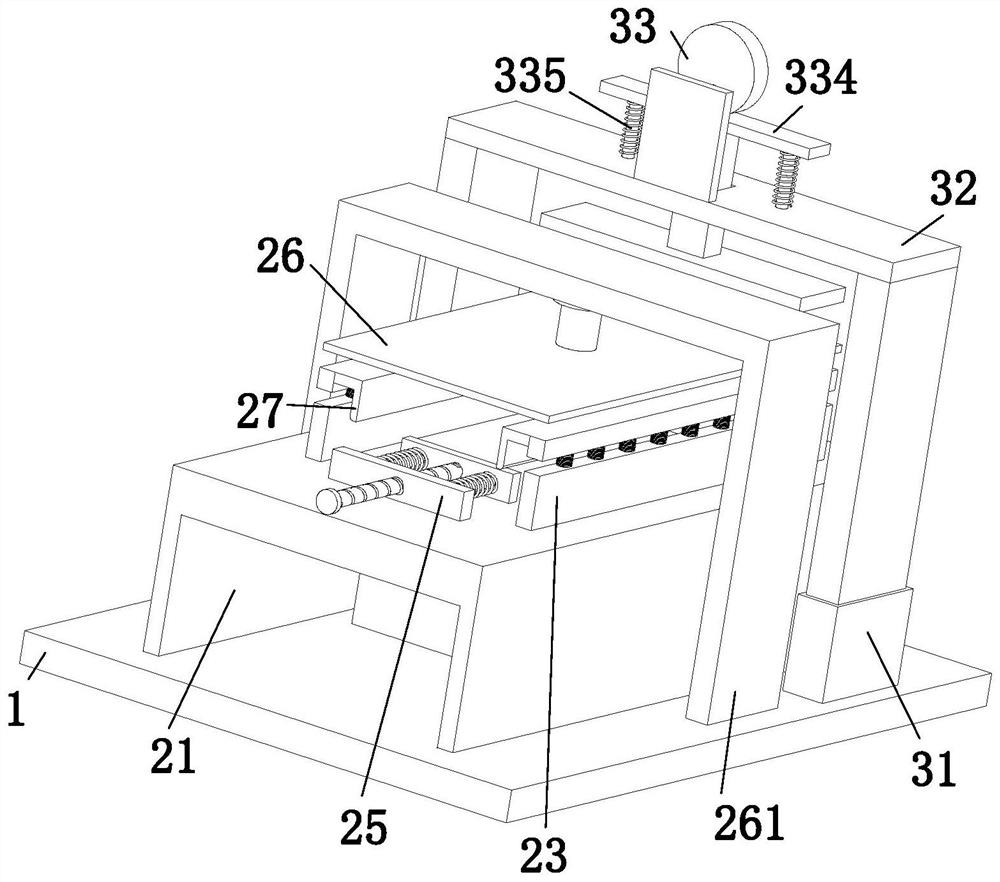

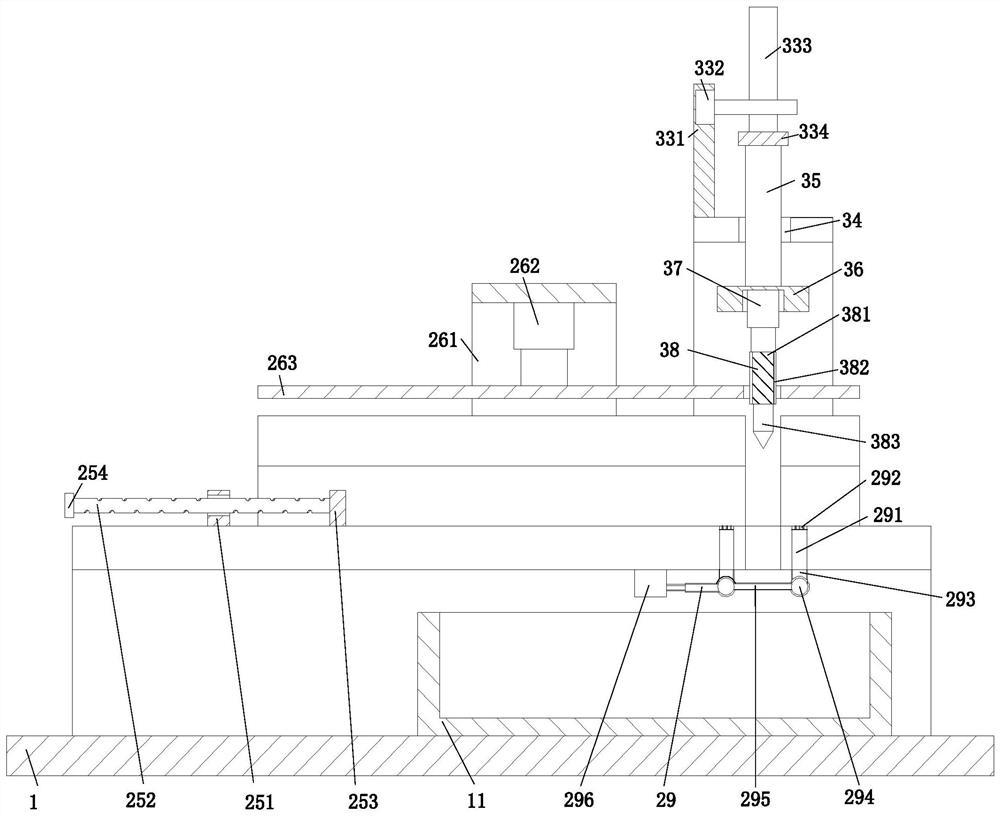

[0037] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9, to further elaborate the present invention.

[0038] A decorative aluminum plate production and cutting machine, including a workbench 1, a fixing device 2 and a cutting device 3, the top of the workbench 1 is provided with a fixing device 2, and the top of the workbench 1 is close to the right side And a cutting device 3 is arranged above the fixing device 2;

[0039] The fixing device 2 includes a No. 1 匚-shaped plate 21, a cutting groove 22, a No. 1 fixing plate 23, a No. 2 fixing plate 24, an adjusting frame 25, a fixing frame 26, a No. 1 clamping frame 27, and a No. 2 clamping frame. 28 and an adsorption frame 29, the top of the workbench 1 is fixedly installed with a No. 1 U-shaped plate 21 with an opening downward, and the top of the No. 1 U-shaped plate 21 is provided with a cutting gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com