Patents

Literature

140results about How to "Avoid affecting the cutting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel bar cutting machine with steel bar fixing function

The invention discloses a steel bar cutting machine with a steel bar fixing function. The steel bar cutting machine comprises a groove, a supporting flat plate, a first air cylinder, an antiskid mat, a cutting motor, a hydraulic cylinder and a waste chip collection groove. The groove is formed to be used for containing one end of a to-be-cut steel bar; when the steel bar needs to move, the supporting flat plate is pulled, then the steel bar is driven to move at the top of a bottom plate, and rapid movement of the steel bar at the top of the bottom plate is achieved; the first air cylinder is firstly utilized for driving a press plate to move downwards to extrude and fix the steel bar; the cutting motor rotates, then a cutting blade on a rotary shaft is driven to rotate, and therefore the steel bar is cut; the hydraulic cylinder continues to drive a hydraulic rod to move downwards, and then cutting of the steel bar is completed; and the waste chip collection groove is formed to be used for collecting waste chips generated when the steel bar is cut, the situation that the environment is contaminated due to the fact that the waste chips are scattered around is avoided, and the practicality of equipment is improved.

Owner:梅芹

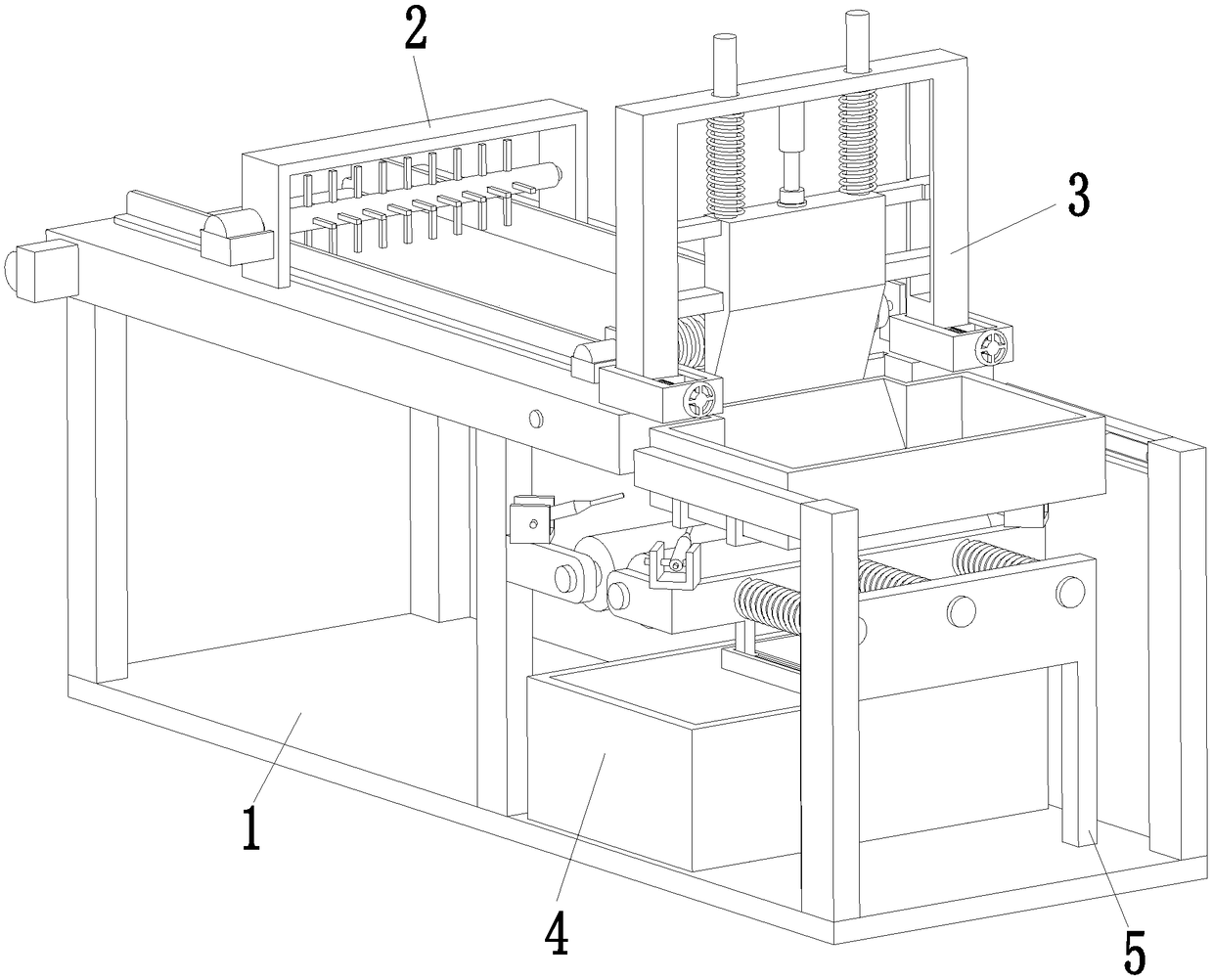

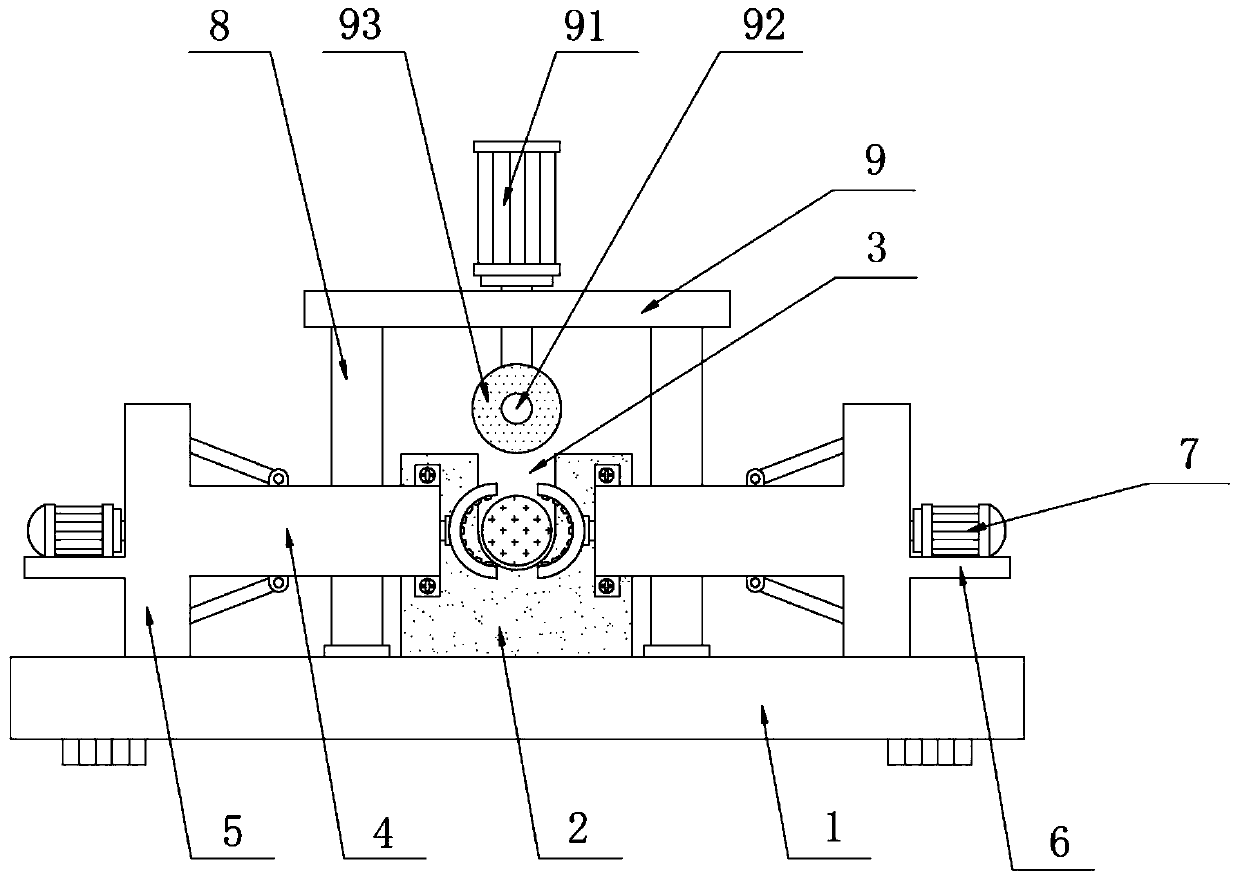

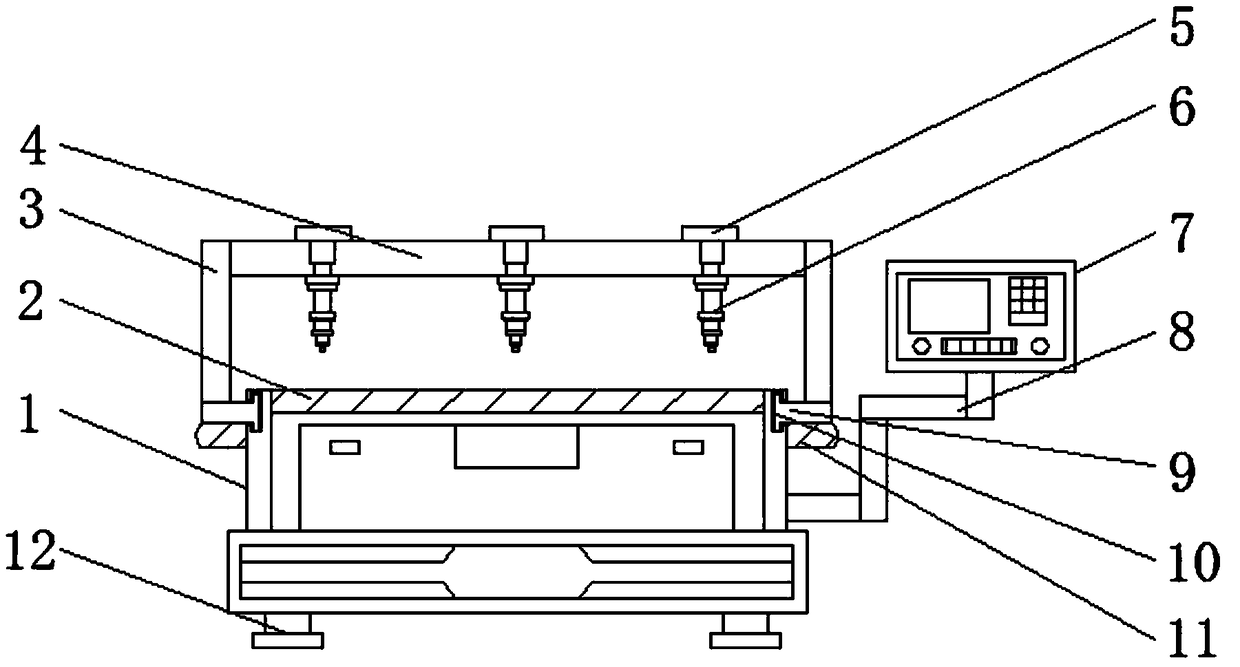

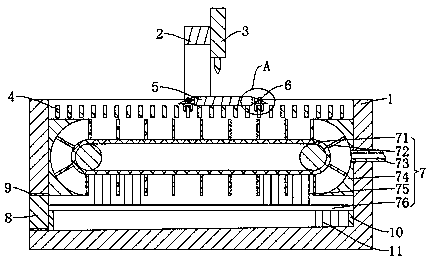

Medicinal material cutting equipment for traditional Chinese medicine decoction piece manufacturing

ActiveCN109278078AEasy to transport and cutReduce manual labor intensityMetal working apparatusEngineeringChinese herbology

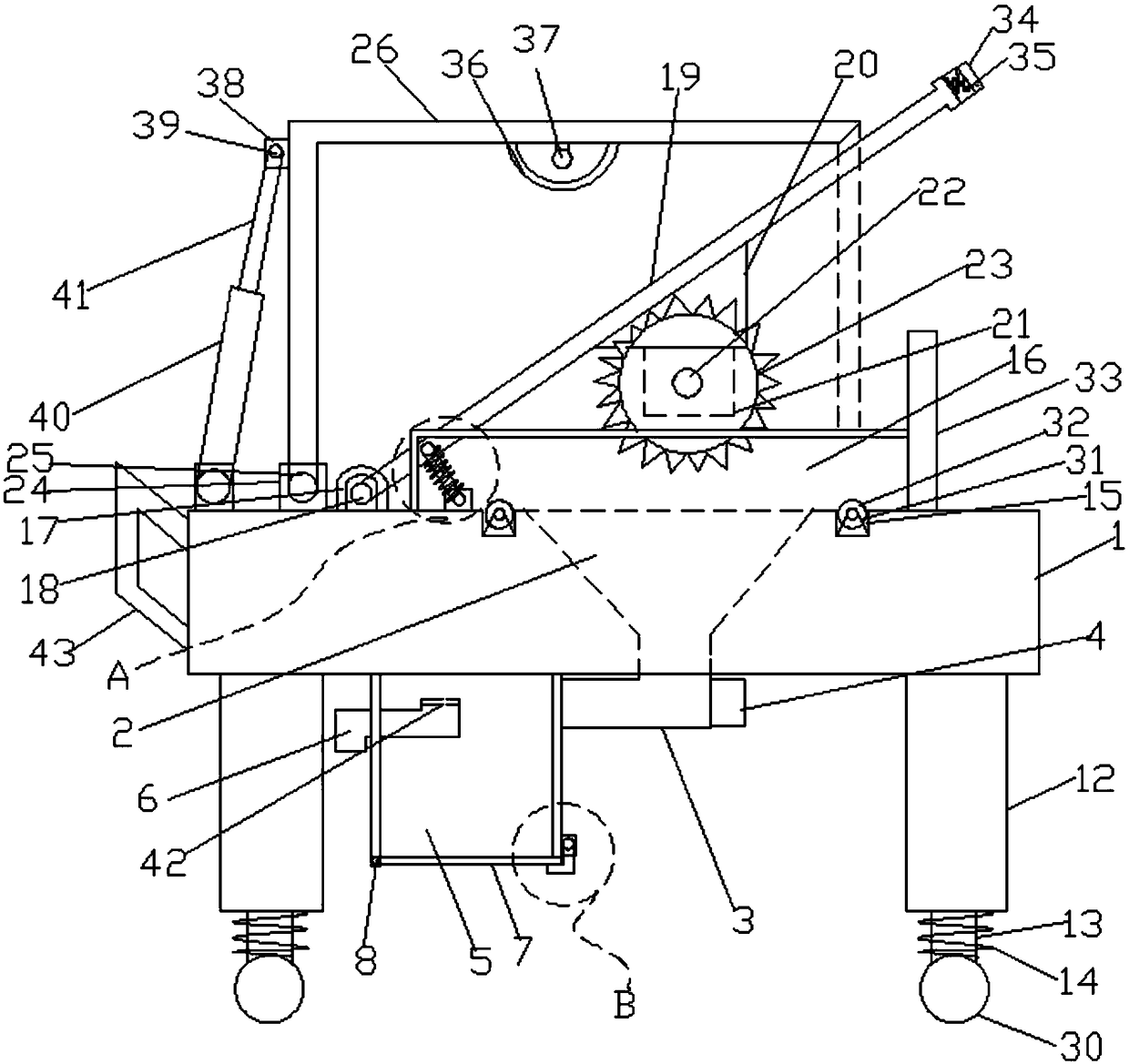

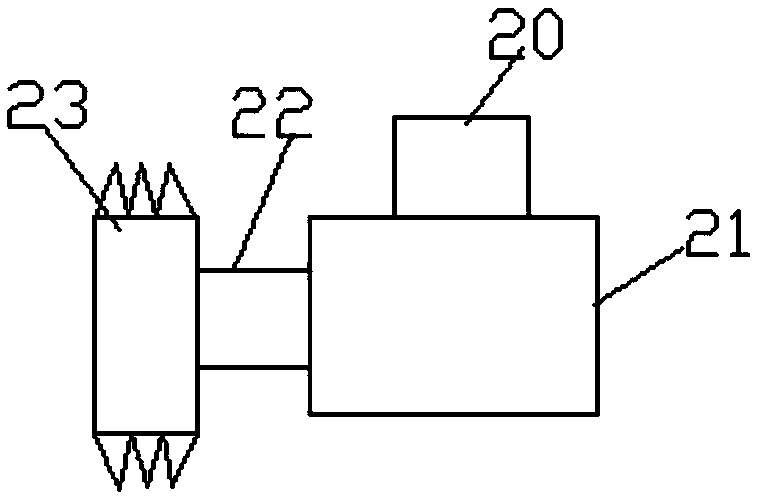

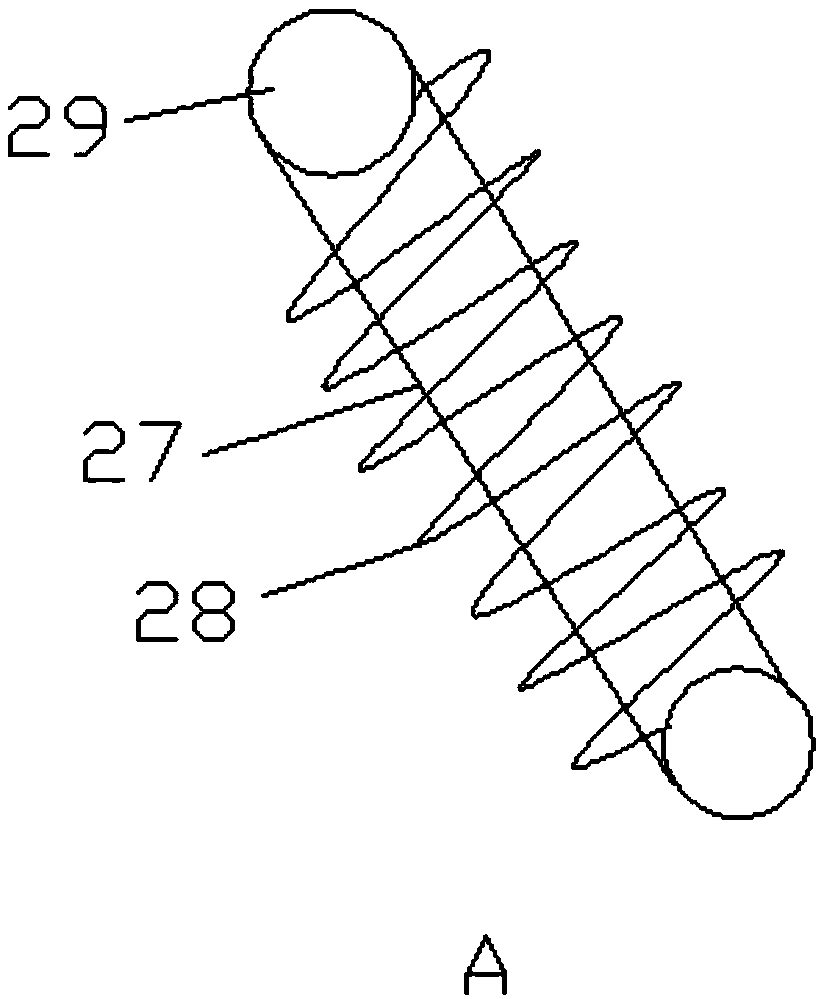

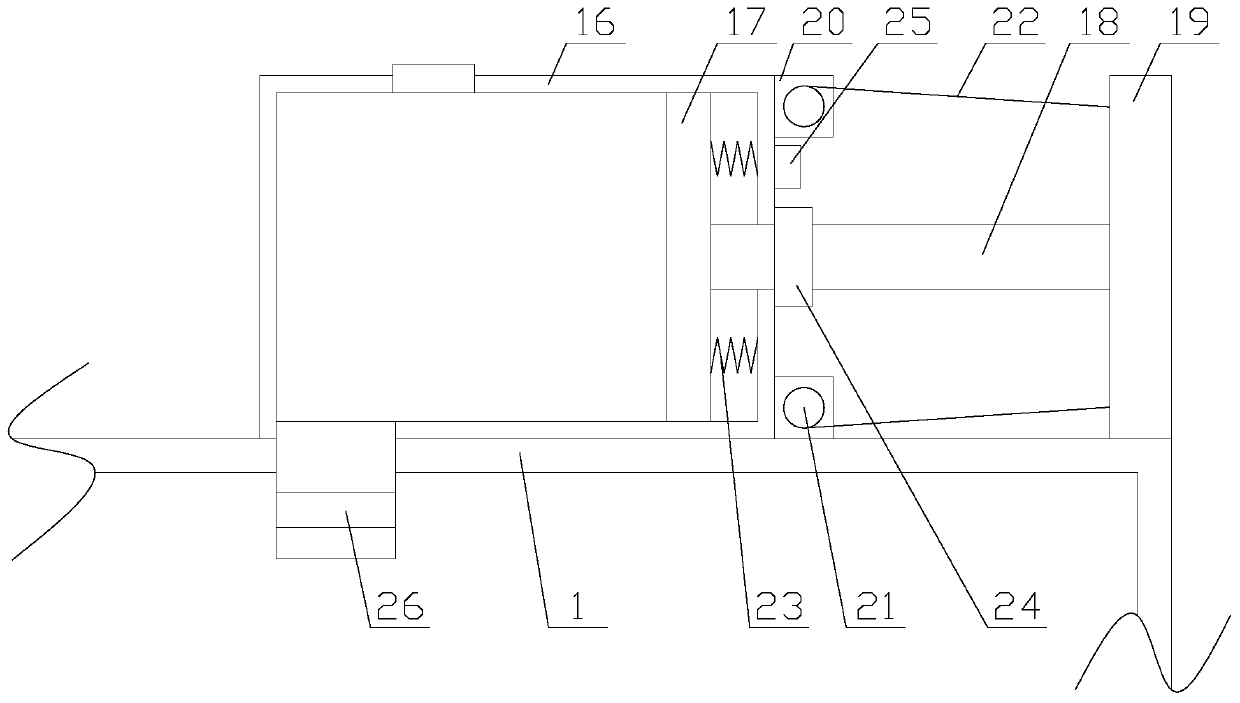

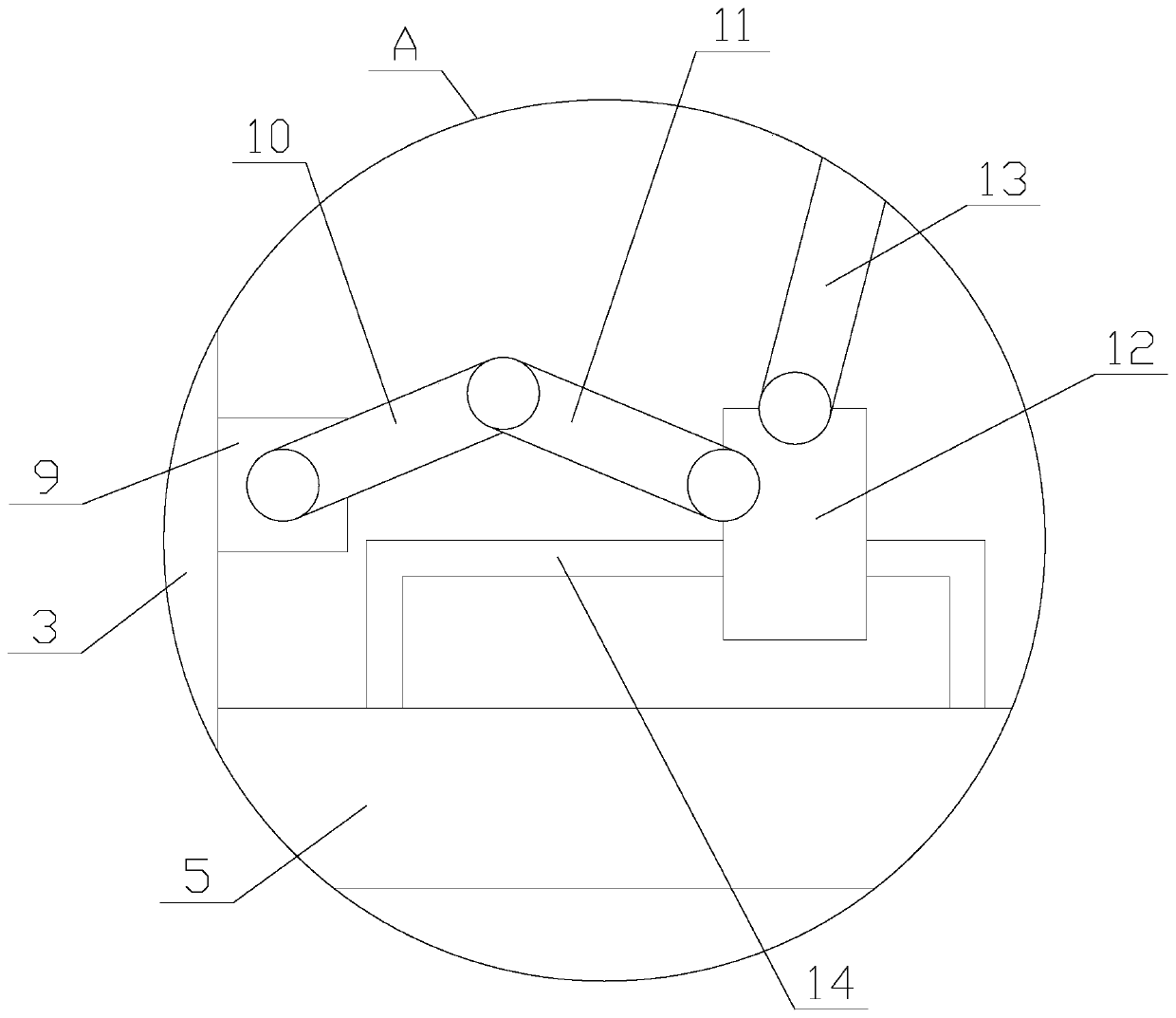

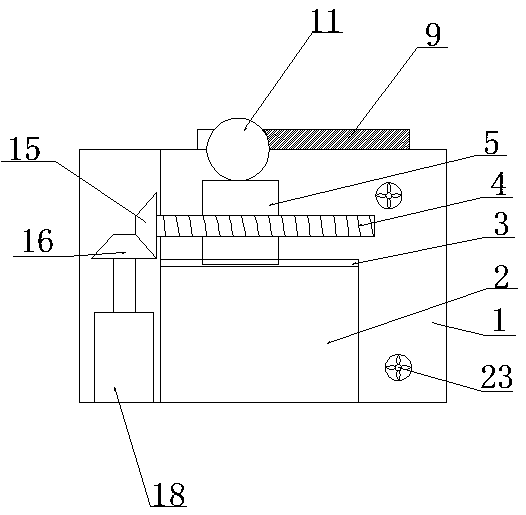

The invention relates to medicinal material cutting equipment for traditional Chinese medicine decoction piece manufacturing. The medicinal material cutting equipment comprises a bottom plate, a conveying device, a cutting device, a cleaning device and a material collecting device. The conveying device is arranged on the left side of the upper end of the bottom plate. The cutting device is arranged at the right end of the conveying device. The right side of the upper end of the bottom plate is provided with the material collecting device. The material collecting device is located on the rightside of the cutting device. The cleaning device is arranged at the upper end of the bottom plate. The cleaning device is located below the cutting device and the material collecting device. The medicinal material cutting equipment can solve the problems that during medicinal material cutting at present, a manual manner is commonly used for conveying and cutting, manual cutting safety is low, the effect is poor, the rejection rate is high, and the cutting length, size and thickness are not uniform; and when fiber and starch containing medicinal materials or medicinal materials containing more sticky liquid and saccharides are cut, residues on the surface of a cutting blade cannot be cleaned, the later cutting effect is influenced, the cut medicinal materials are manually collected, and thelabor intensity of manual work is increased.

Owner:江西一方天江药业有限公司

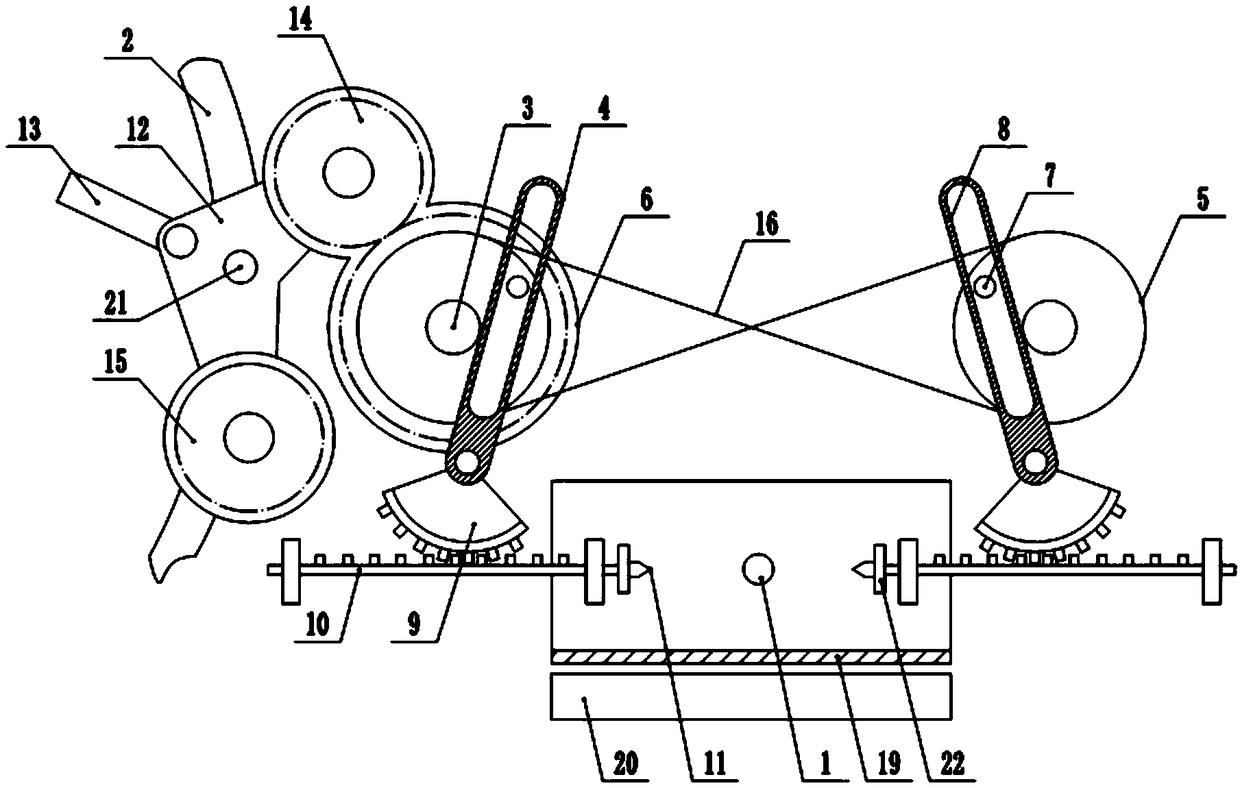

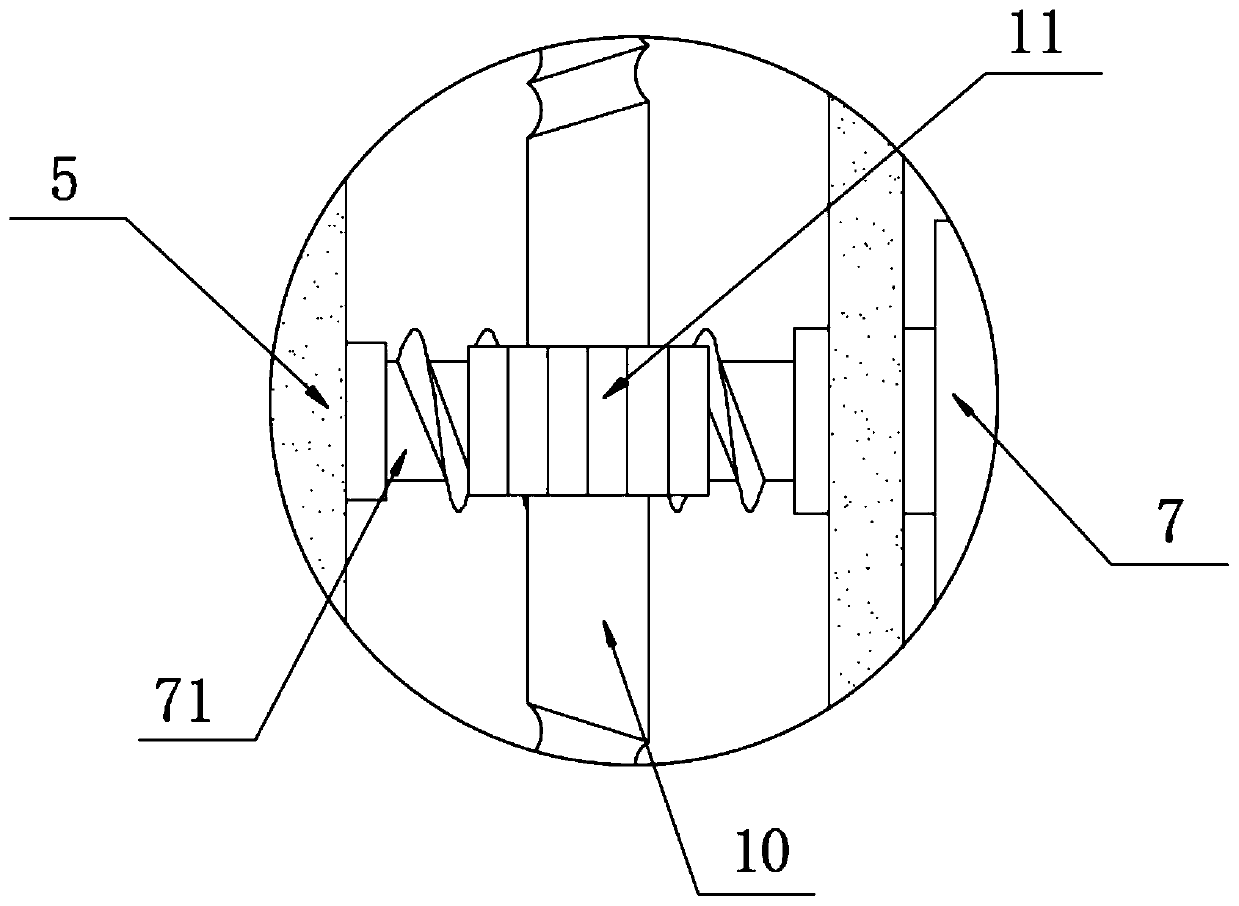

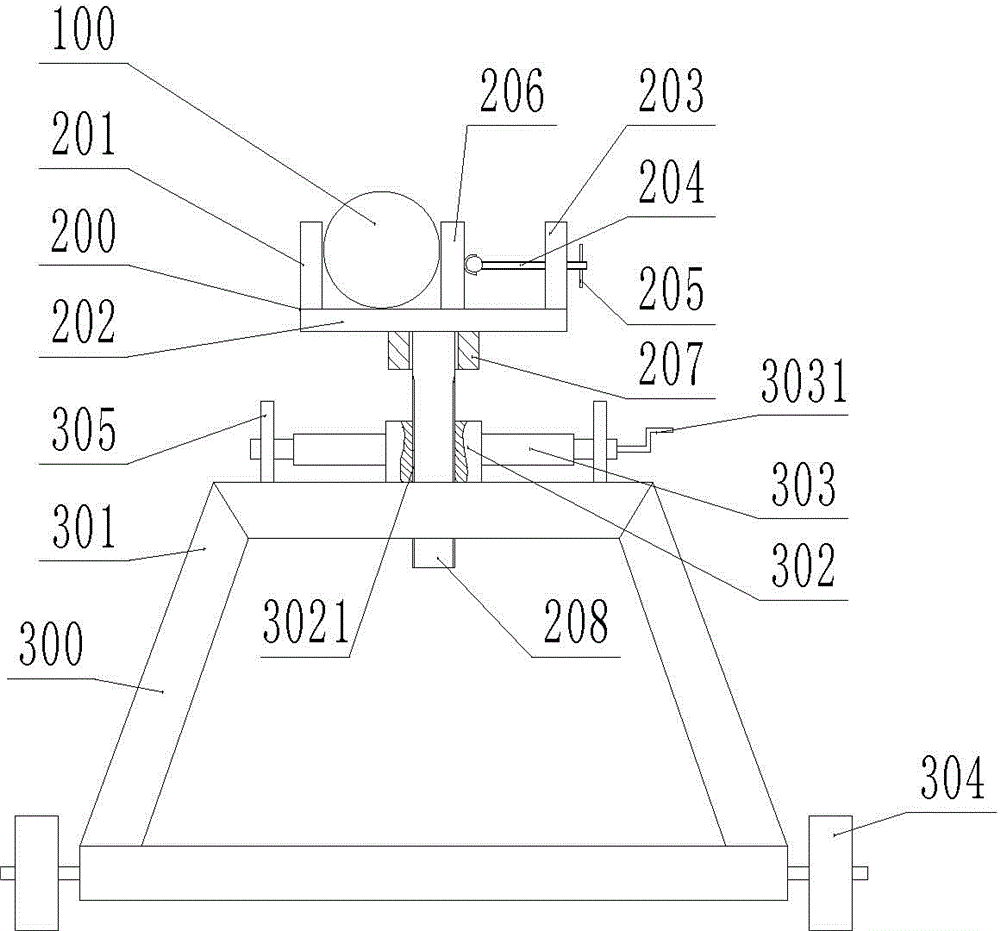

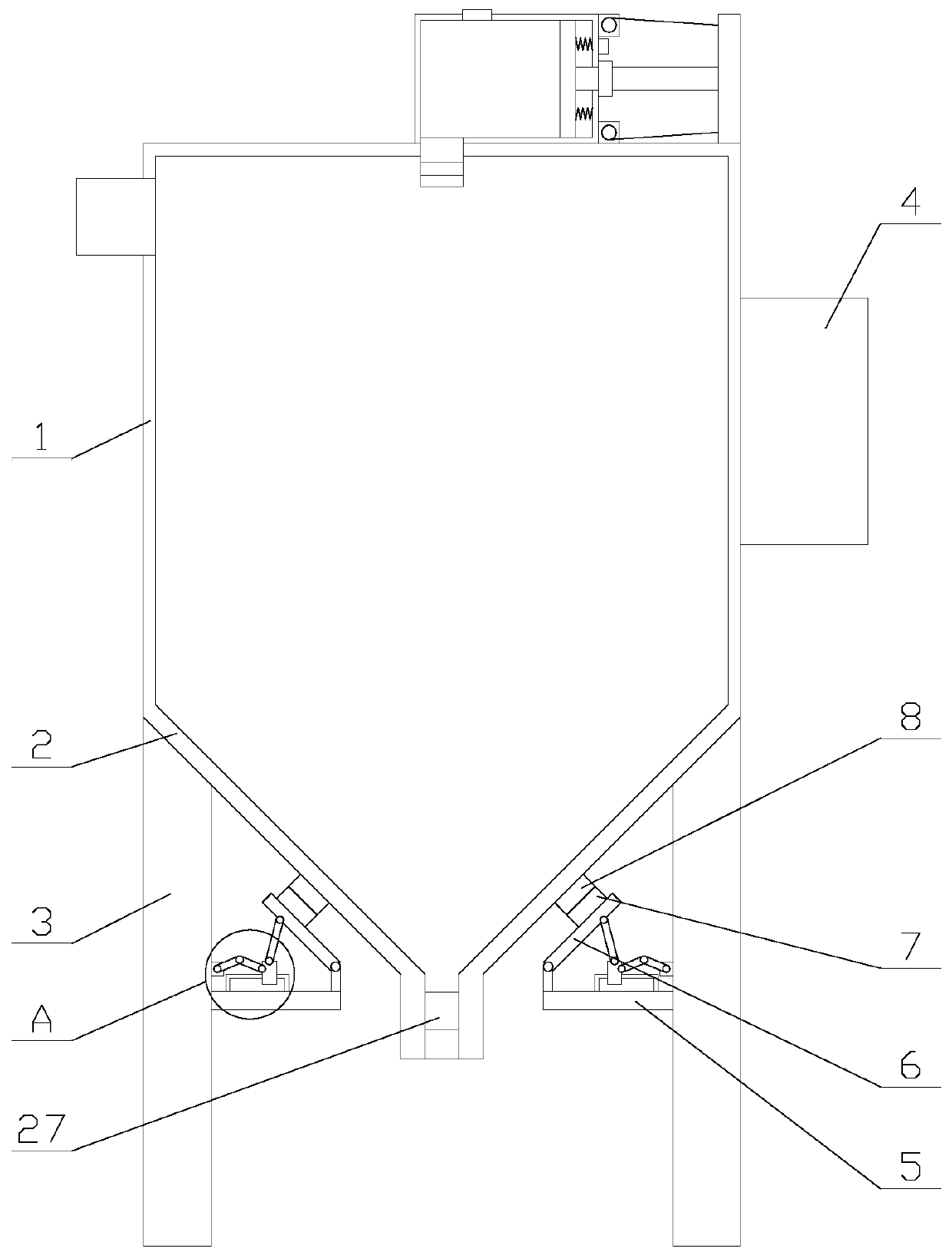

Cutting machine of fodder for giant salamanders

ActiveCN108789522AReduce swing frequencyIncrease the lengthFeeding-stuffMetal working apparatusGiant salamanderEngineering

The invention relates to a cutting machine of fodder for giant salamanders. The cutting machine comprises a machine frame, a first cutting mechanism and a driving mechanism. The machine frame is arranged close to an extrusion opening of a fodder hot-extrusion machine; the first cutting mechanism comprises a rotating shaft and a push rod, the rotating shaft is coaxially and fixedly connected with arotating disc, and the eccentric position of the rotating disc is fixedly connected with a supporting column; the lower portion of the push rod is rotatably connected to the machine frame, a slidinggroove is formed in the upper portion of the push rod in the length direction of the push rod, and the supporting column is slidably connected into the sliding groove; the bottom end of the push rod is fixedly connected with a sector gear, the sector gear is engaged with a rack, the rack is slidably connected to the machine frame, and cutting knife sets used for cutting the fodder are arranged atthe end of the rack; and the driving mechanism comprises a supporting plate rotatably connected to the machine frame, a swing rod is fixedly connected to the supporting plate, the two ends of the supporting plate are rotatably connected with a driving gear and a notched gear correspondingly, the rotating shaft is coaxially and fixedly connected with a rotating gear, and both the driving gear and the notched gear are engaged with the rotating gear intermittently. The cutting machine can cut the fodder in different lengths.

Owner:江苏拓诚农业发展有限公司

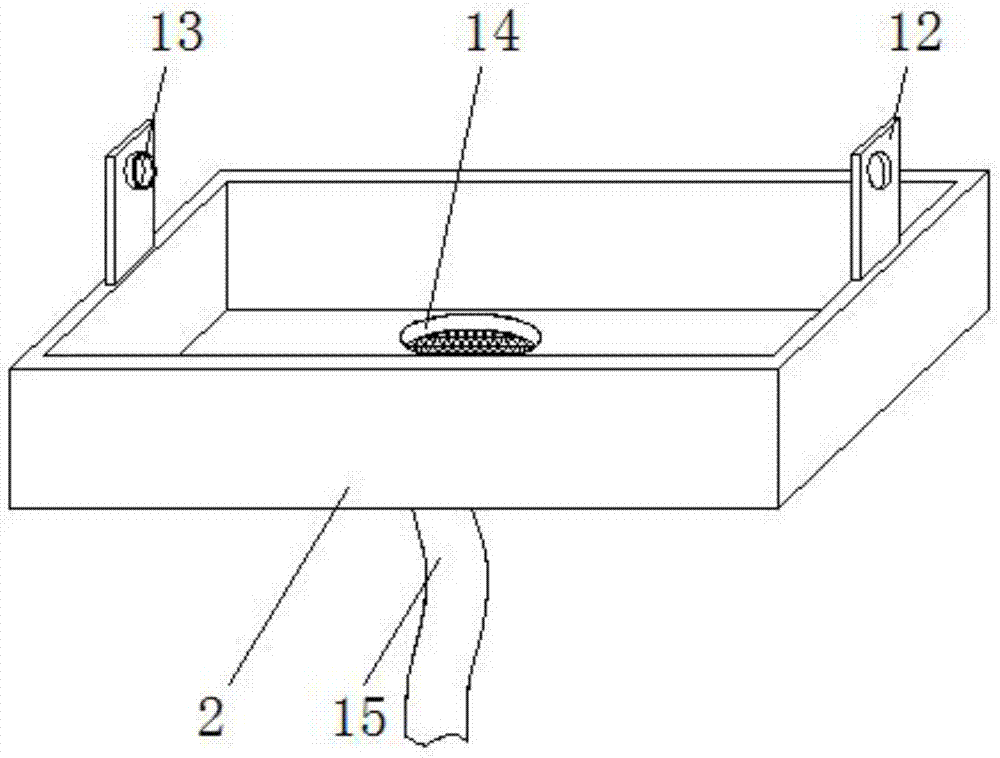

Plate cutting device capable of collecting chippings conveniently

InactiveCN109465910AEasy to collectLess Sweeping CharactersCircular sawsBark-zones/chip/dust/waste removalEngineeringExhaust pipe

The invention discloses a plate cutting device capable of collecting chippings conveniently. The plate cutting device comprises a workbench. Support legs are correspondingly arranged at the corners ofthe bottom end of the workbench. First telescopic rods are correspondingly arranged at the bottom ends of the support legs. First springs are correspondingly arranged on the outer sides of the firsttelescopic rods. A chipping collecting port is formed in the middle part in the workbench. A chipping collecting pipe is arranged at the bottom end of the chipping collecting port. A fan is arranged at one side of the chipping collecting pipe. A chipping collecting box is arranged on the side away from the fan and on one side of the chipping collecting pipe. An air exhaust pipe is arranged on theside away from the chipping collecting pipe and on one side of the chipping collecting box. A bottom cover is arranged at the bottom end of the chipping collecting box. The side, at the same side as the air exhaust pipe, of the bottom cover is connected with the chipping collecting box through a sixth connecting shaft. A fourth fixing block is arranged on the one side of the bottom end of the chipping collecting box and the side away from the sixth connecting shaft, a fourth connecting shaft is arranged in the middle of the fourth fixing block, a fixing rod is arranged on the fourth connectingshaft, the fixing rod is in an L shape, and grooves are symmetrically formed in the two sides of the top end of the chipping collecting port and positioned in the top end of the workbench.

Owner:嘉善顺源金属制品有限公司

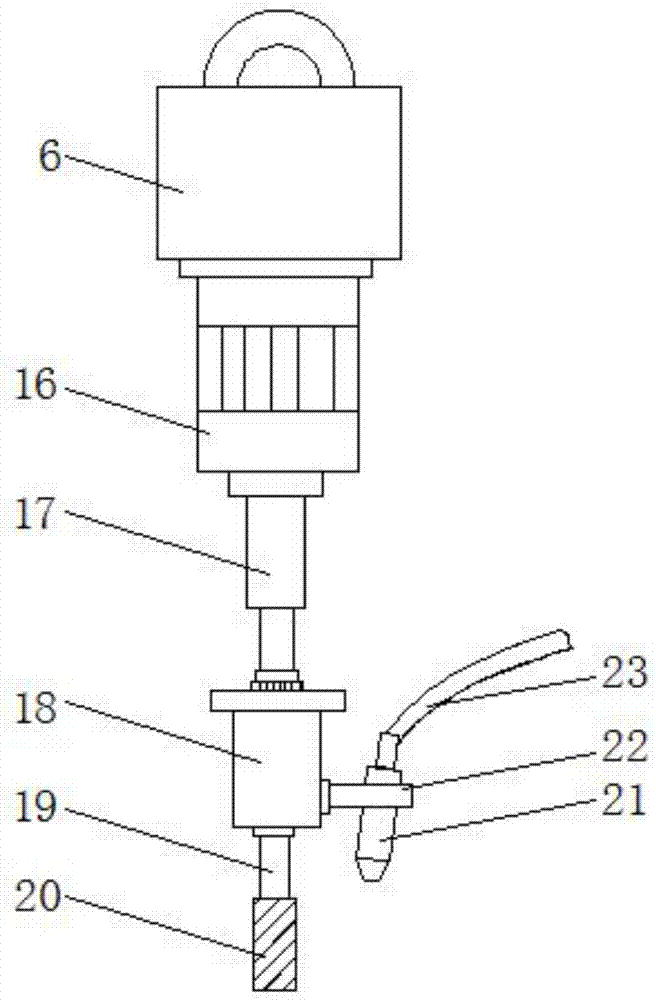

Cutting device for vehicle rubber pipe production

InactiveCN107283480ARealize the heat dissipation functionRealize left and right sliding adjustmentMetal working apparatusRotational axisHydraulic cylinder

The invention discloses a cutting device for the production of automobile rubber tubes, which comprises a machine body and a frame. A sliding track is horizontally arranged on the top of the frame, and a sliding block is slidably installed on the sliding track. There is a hydraulic cylinder, the bottom end of the hydraulic cylinder is connected with the rotary motor through the piston rod, the bottom end of the rotary motor is connected with the cutting head through the rotating shaft, and a cooling liquid nozzle is arranged on one side of the cutting head, so A coolant tank is installed on the top of one side of the frame, and a cutting groove is arranged on the top of the body. The invention can realize the precise cutting of the pipe material, and the cutting effect is good. Through the cooling liquid nozzle provided on one side of the cutting head, the heat dissipation function of the cutting head can be realized, so as to avoid the overheating of the cutting head after working for a long time. Cutting effect, can reduce the dust generated in the cutting process, reduce pollution, and simple structure, easy to use, strong practicability.

Owner:枞阳县金源汽车零部件有限公司

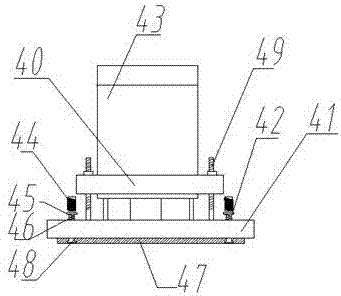

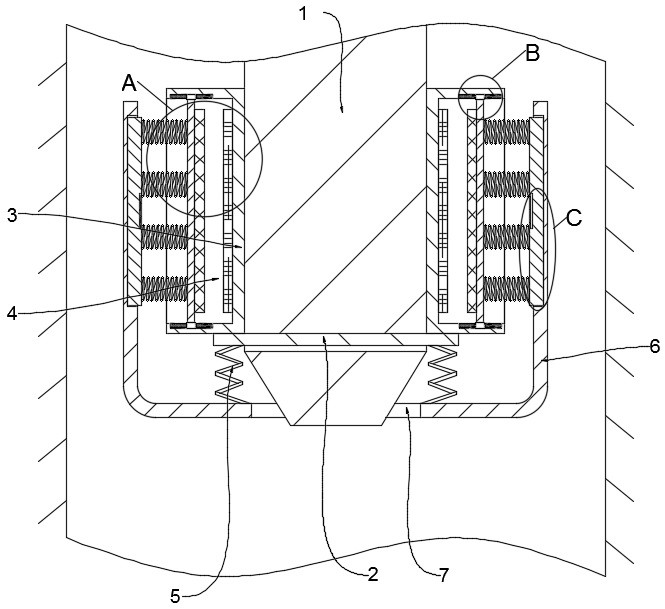

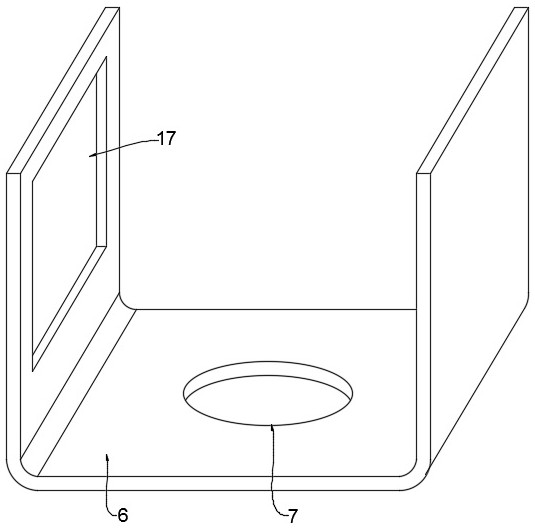

Punching and positioning device for jewelry processing

The invention relates to the field of jewelry processing, and in particular to a punching and positioning device for jewelry processing. The punching and positioning device for the jewelry processingcomprises a machine body and an operation cavity arranged in the machine body, a support plate and a sliding plate located below the support plate are slidingly arranged in the operation cavity, a cylinder is fixedly arranged in the sliding plate, and a through hole penetrating vertically is formed in the cylinder. The punching and positioning device for the jewelry processing provided by the invention can realize punching the jewelry successively, the device is internally provided with a circulating water cooling device, which can cool the jewelry when the jewelry is cut, so as to prevent anoverheating bit from affecting the cutting effect. Meanwhile, a fixing device arranged in the device can easily fix the jewelry, and automatically locate the jewelry when punching, the operation is very simple, the efficiency is high, the device can collect the jewelry debris in a coolant to avoid the loss of property, and the device is convenient for production and promotion.

Owner:深圳市艺精金黄金珠宝有限公司

Industrial roller brush carrier roller automatic cutting device with high cutting efficiency

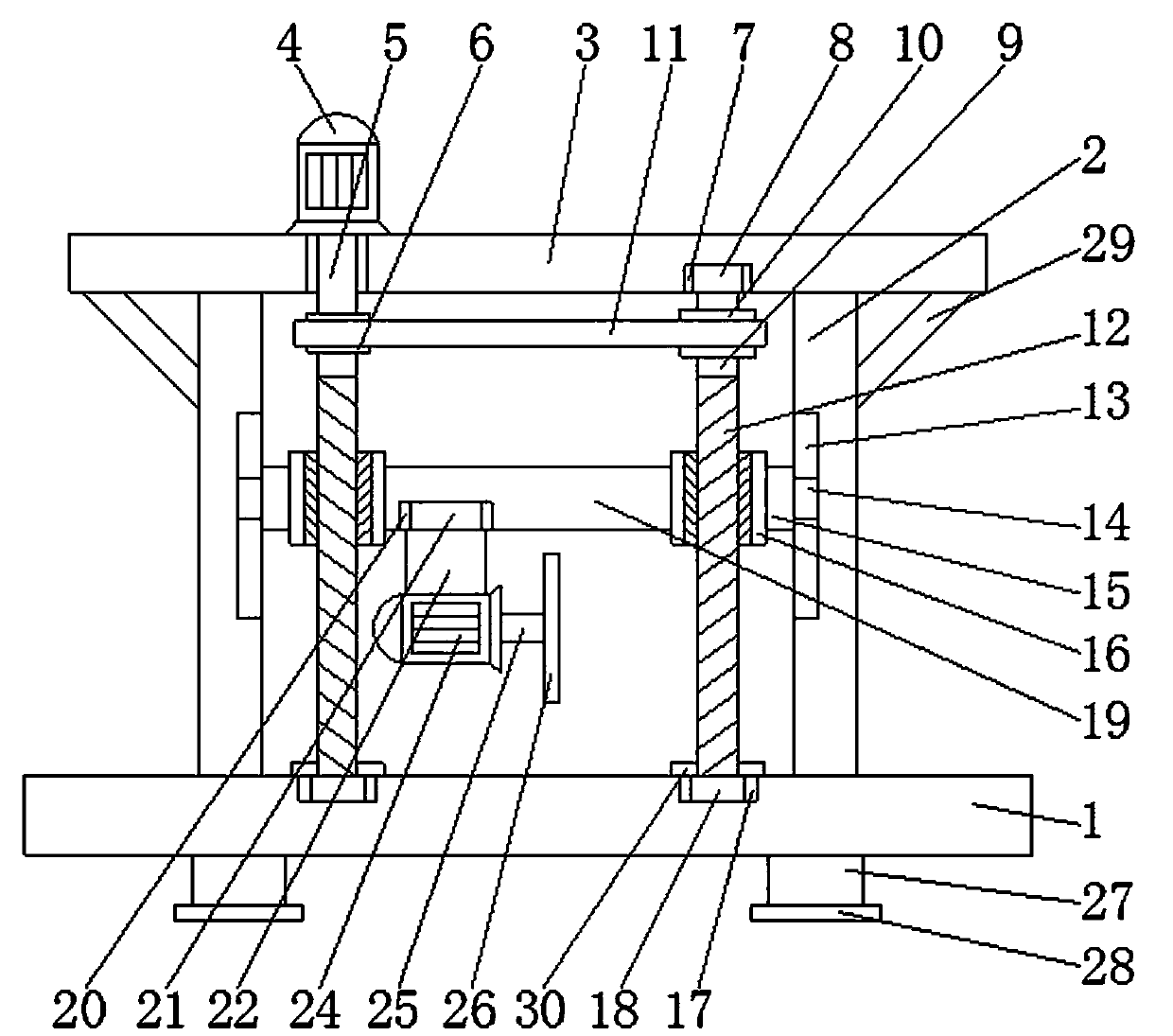

InactiveCN110394501AImprove safety performanceReduce labor intensityPositioning apparatusMaintainance and safety accessoriesElectric machineryEngineering

The invention discloses an industrial roller brush carrier roller automatic cutting device with high cutting efficiency. The industrial roller brush carrier roller automatic cutting device comprises aworkbench, two fixing blocks are symmetrically arranged on the upper surface of the workbench, containing grooves matched with a carrier roller are formed in the upper surfaces of the fixing blocks,moreover, first fixing cylinders are fixedly connected to the front surfaces of the two sides of the fixing blocks through bolts, and second fixing cylinders are arranged at one ends of the first fixing cylinders. The invention relates to the technical field of roller brush carrier roller cutting. According to the industrial roller brush carrier roller automatic cutting device with the high cutting efficiency, one ends of servo motors are installed on one side surfaces of the second fixing cylinders in an embedded and rotating mode, when the carrier roller is cut, the carrier roller can be automatically clamped and firmly fixed, so that the situation that the cutting effect is affected due to the fact that the carrier roller shakes during cutting is prevented, the industrial roller brush carrier roller automatic cutting device replaces the operation of manually holding the carrier roller by hands for fixing, so that the safety performance is improved, meanwhile, the labor intensity ofworkers is reduced, and the practicability is high.

Owner:潜山市志杰刷业有限公司

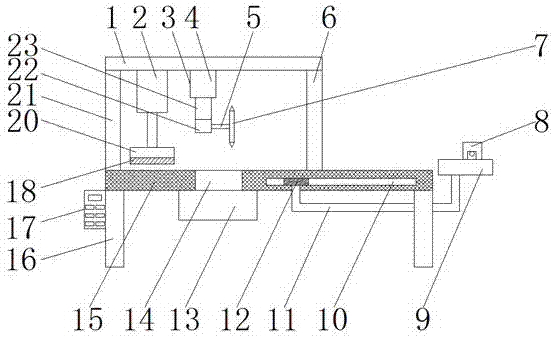

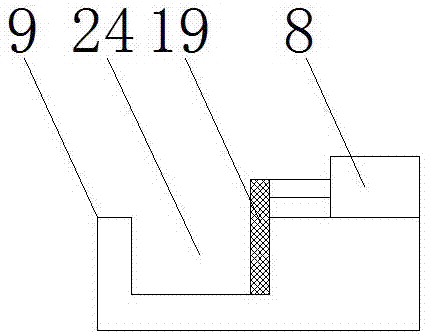

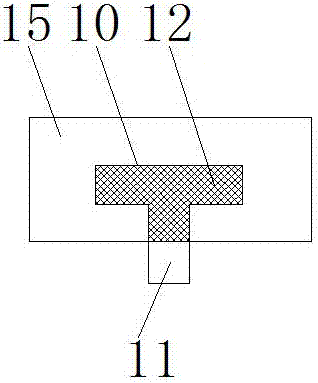

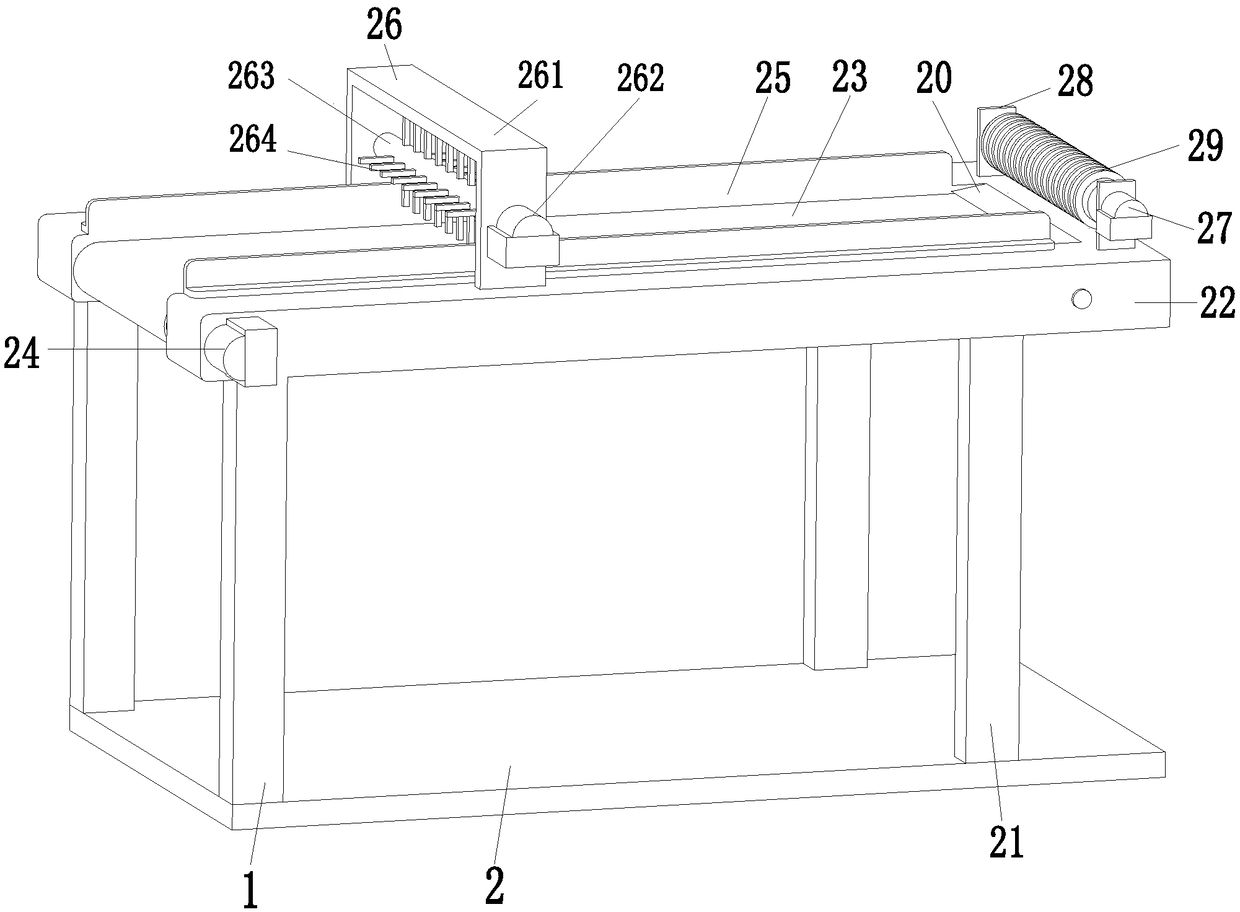

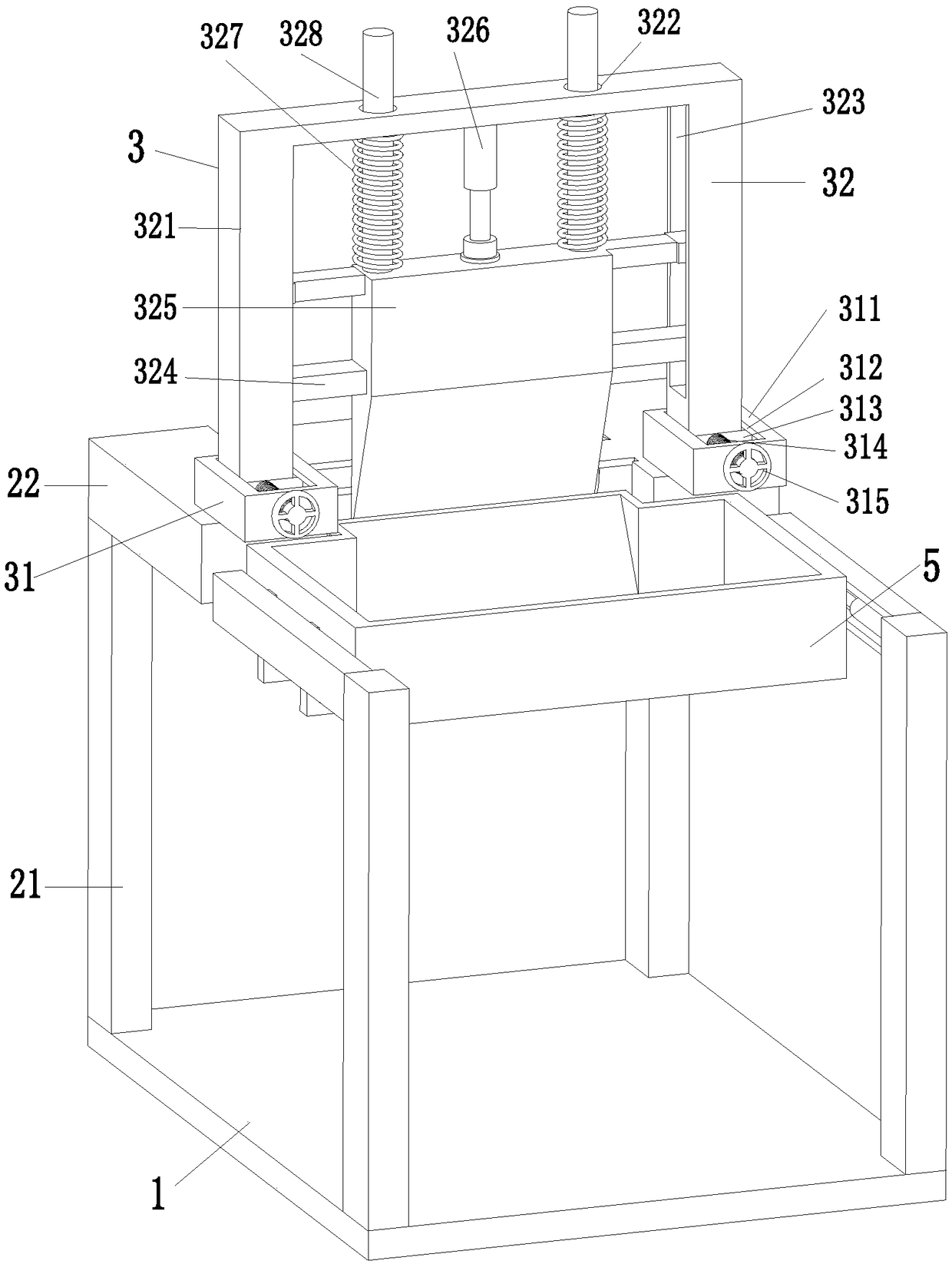

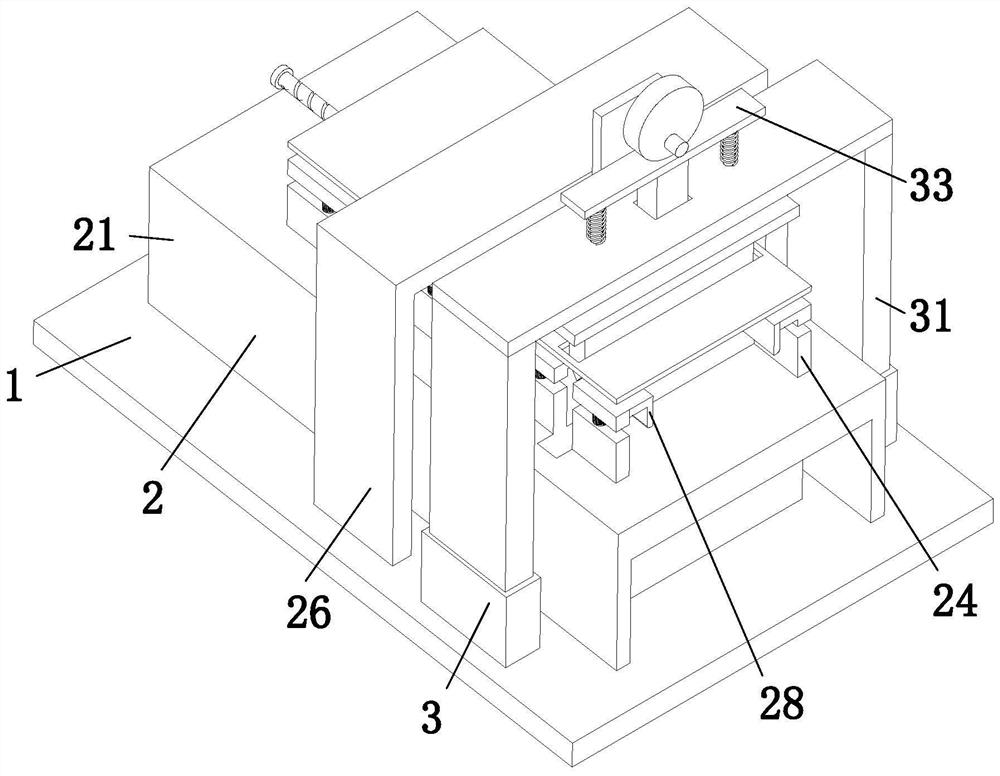

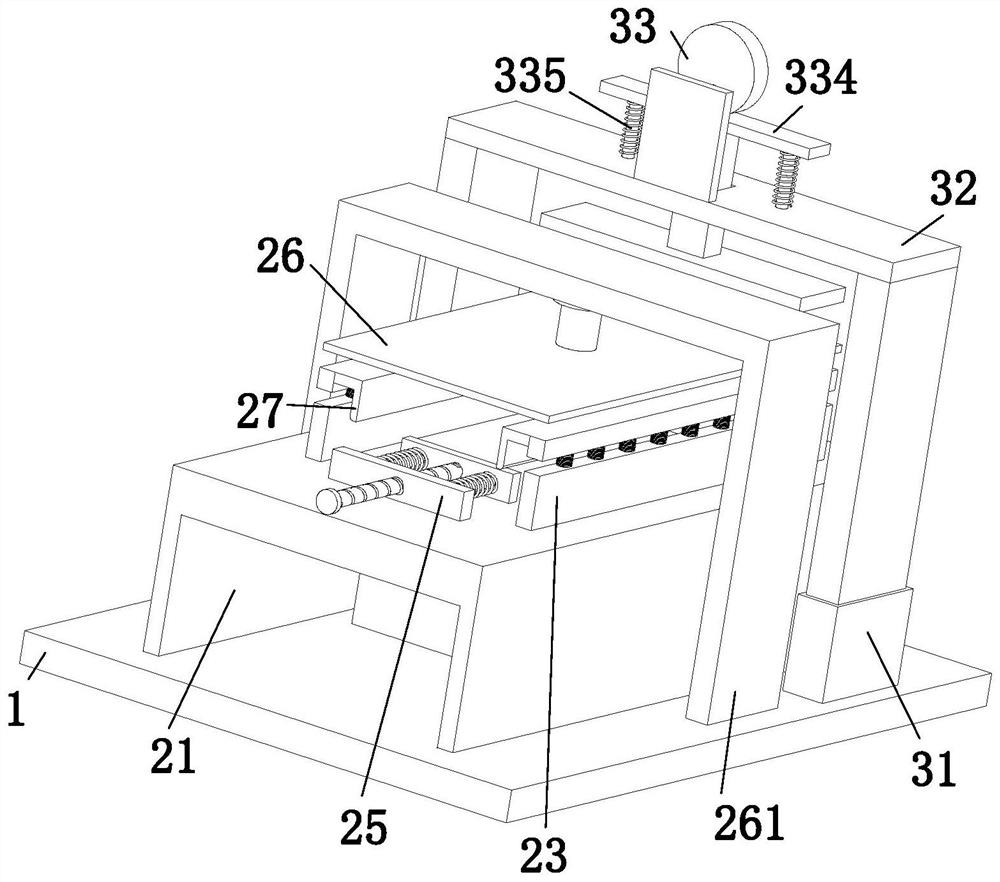

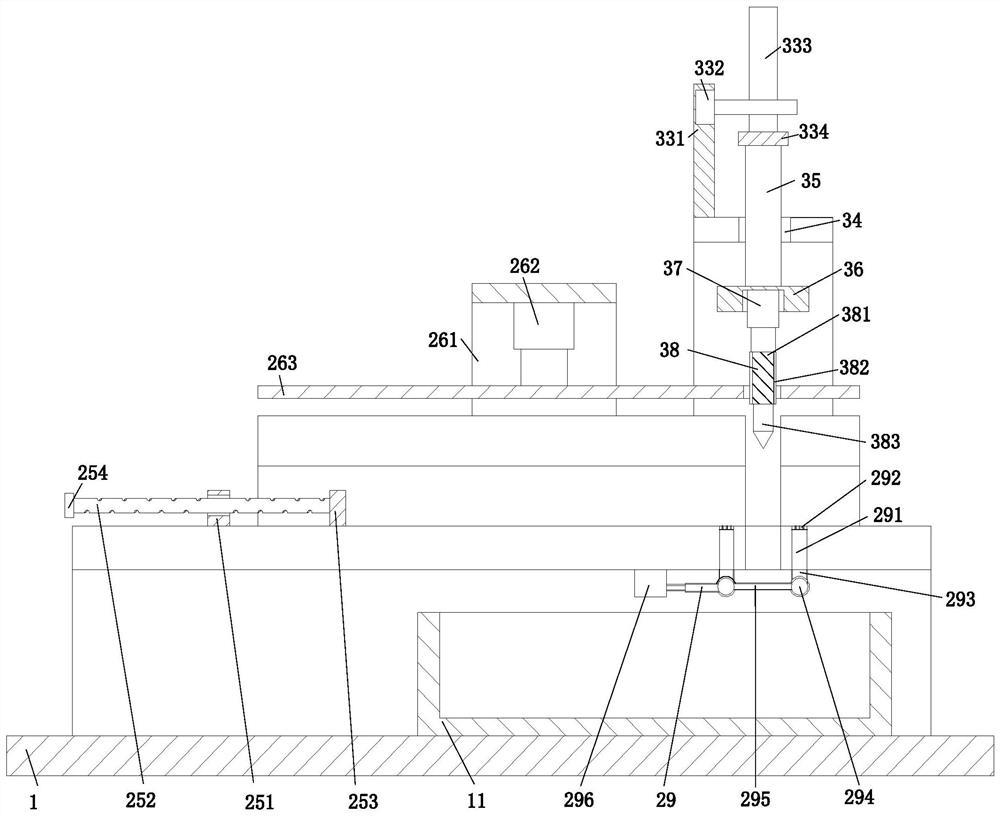

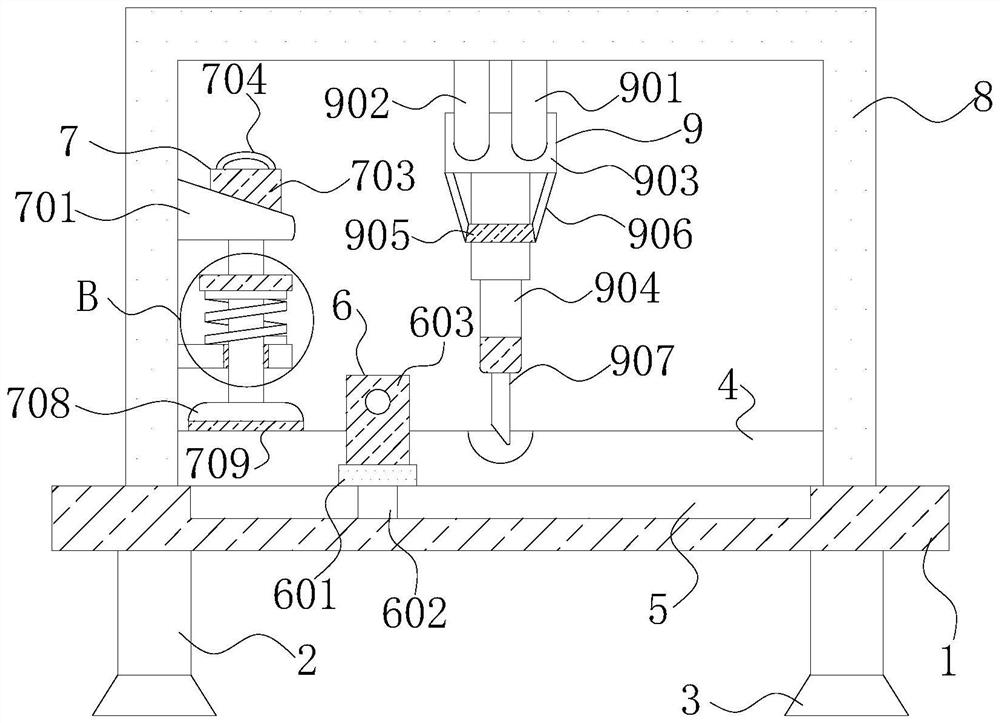

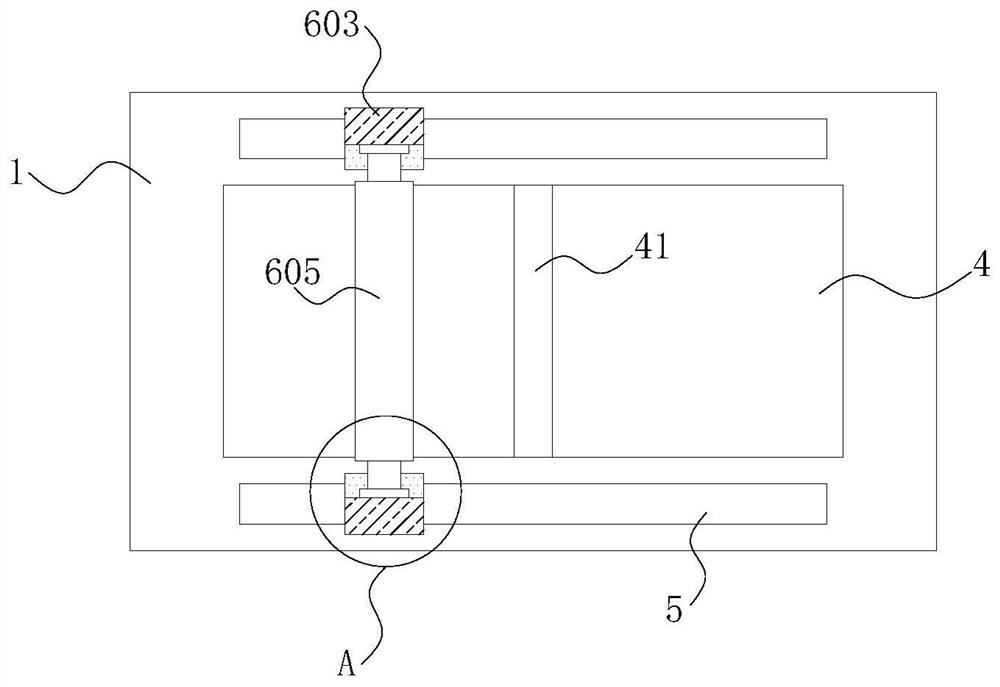

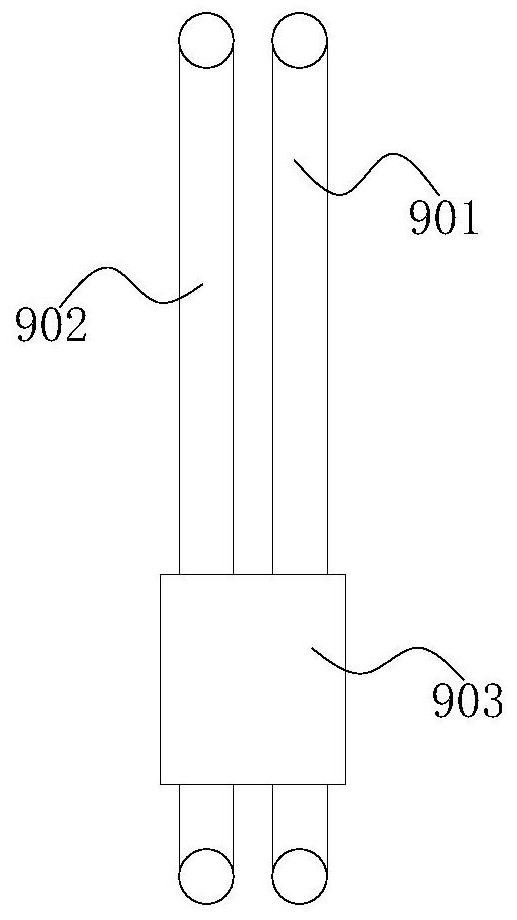

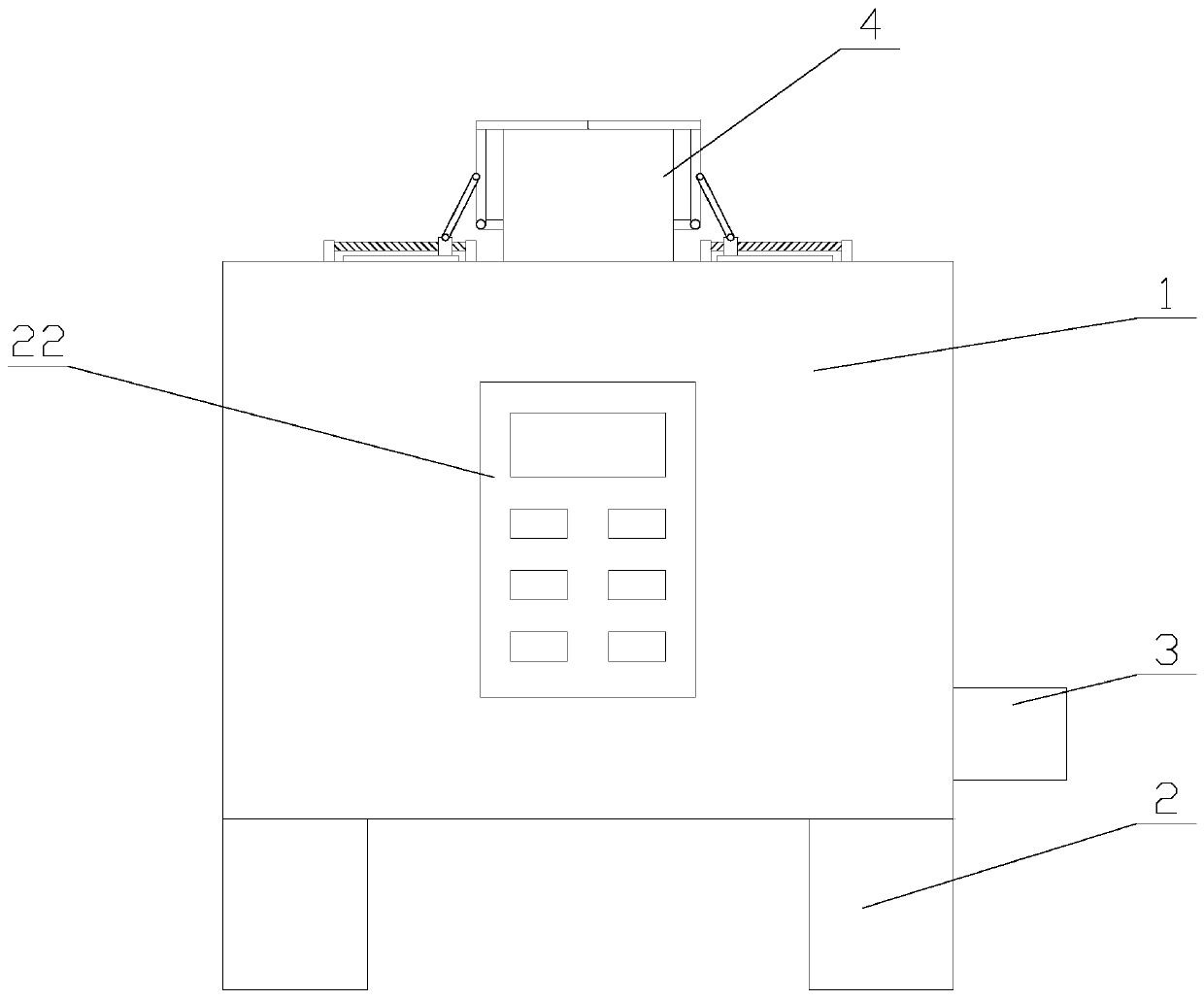

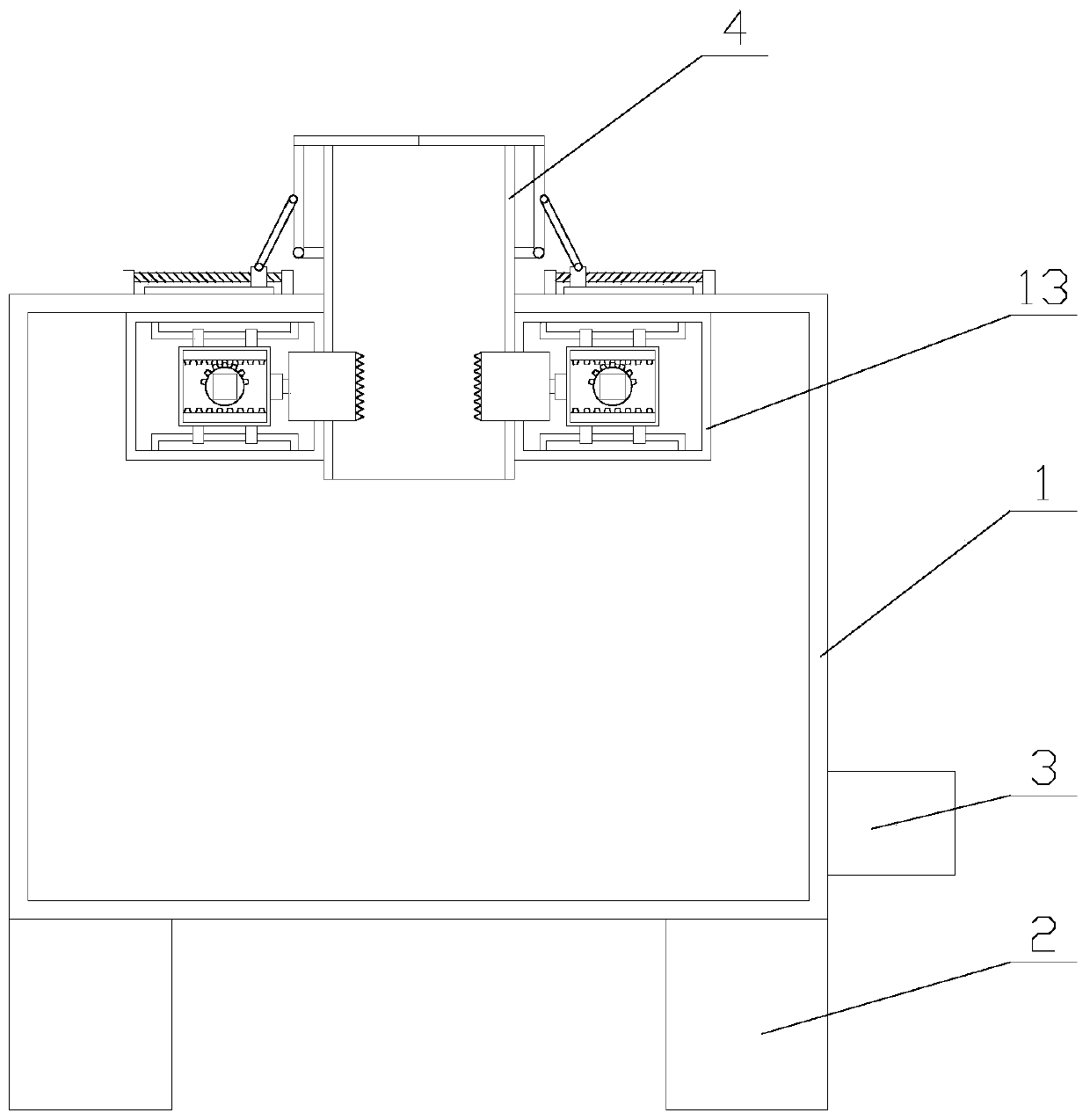

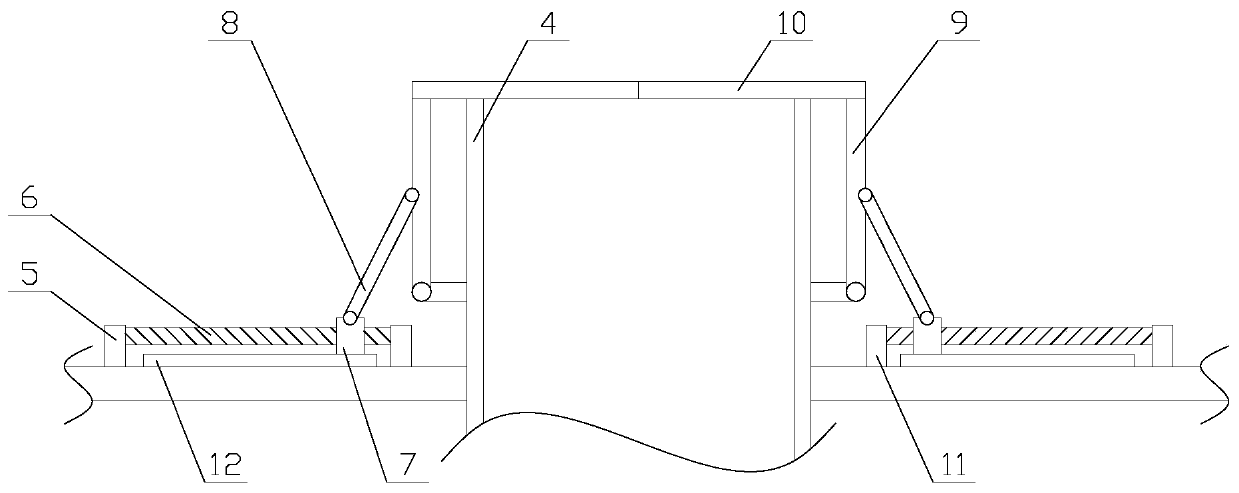

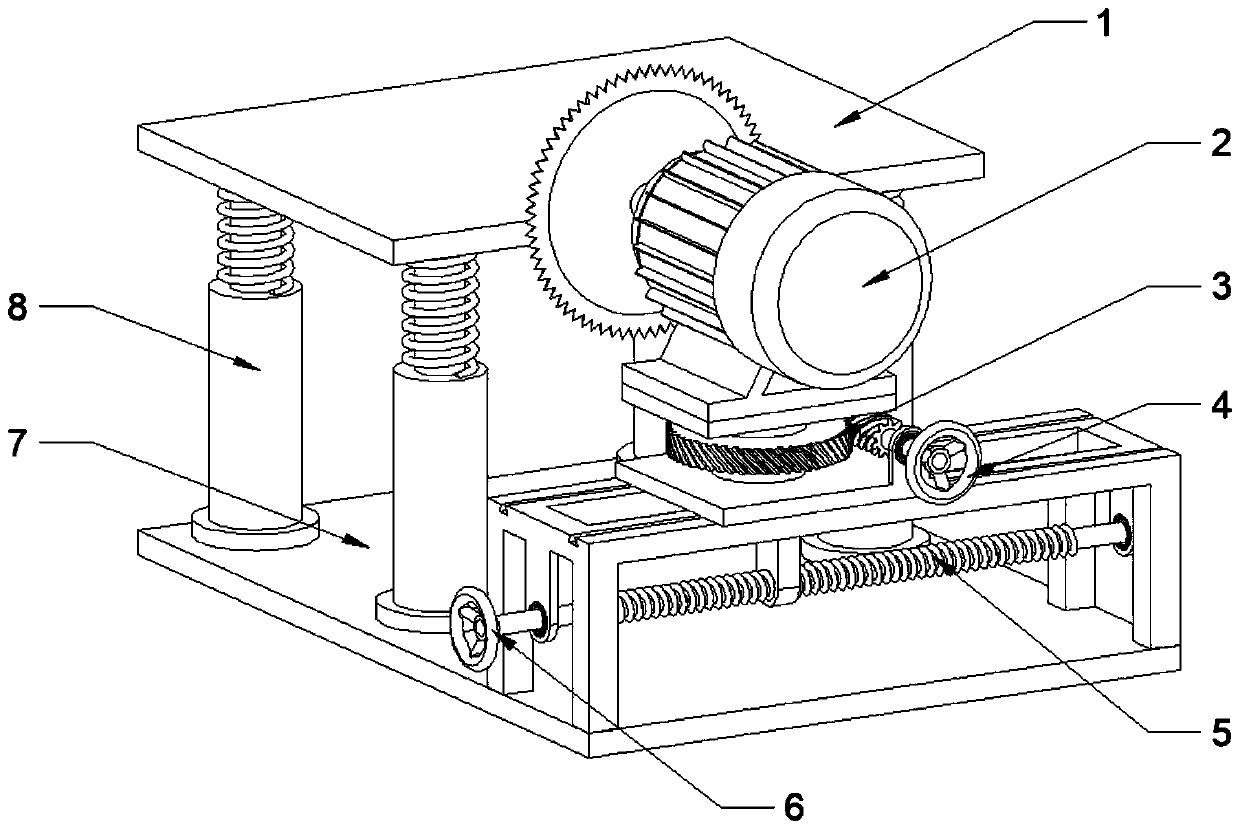

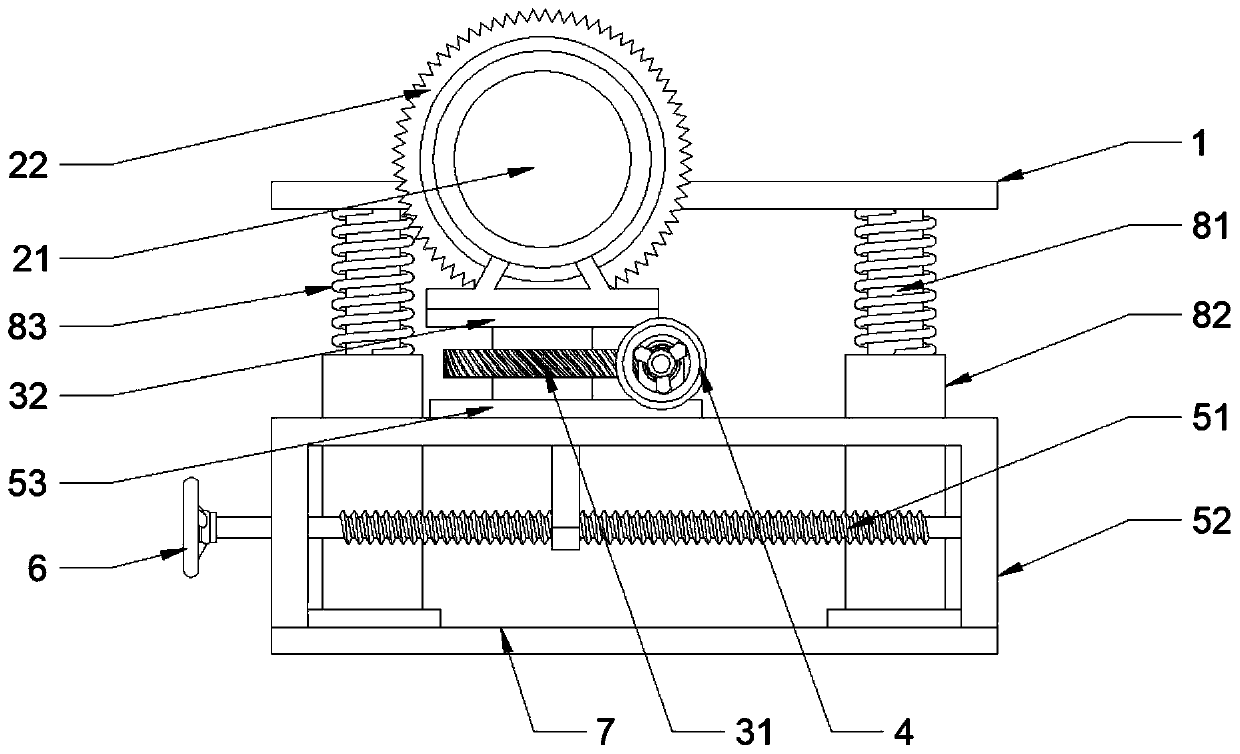

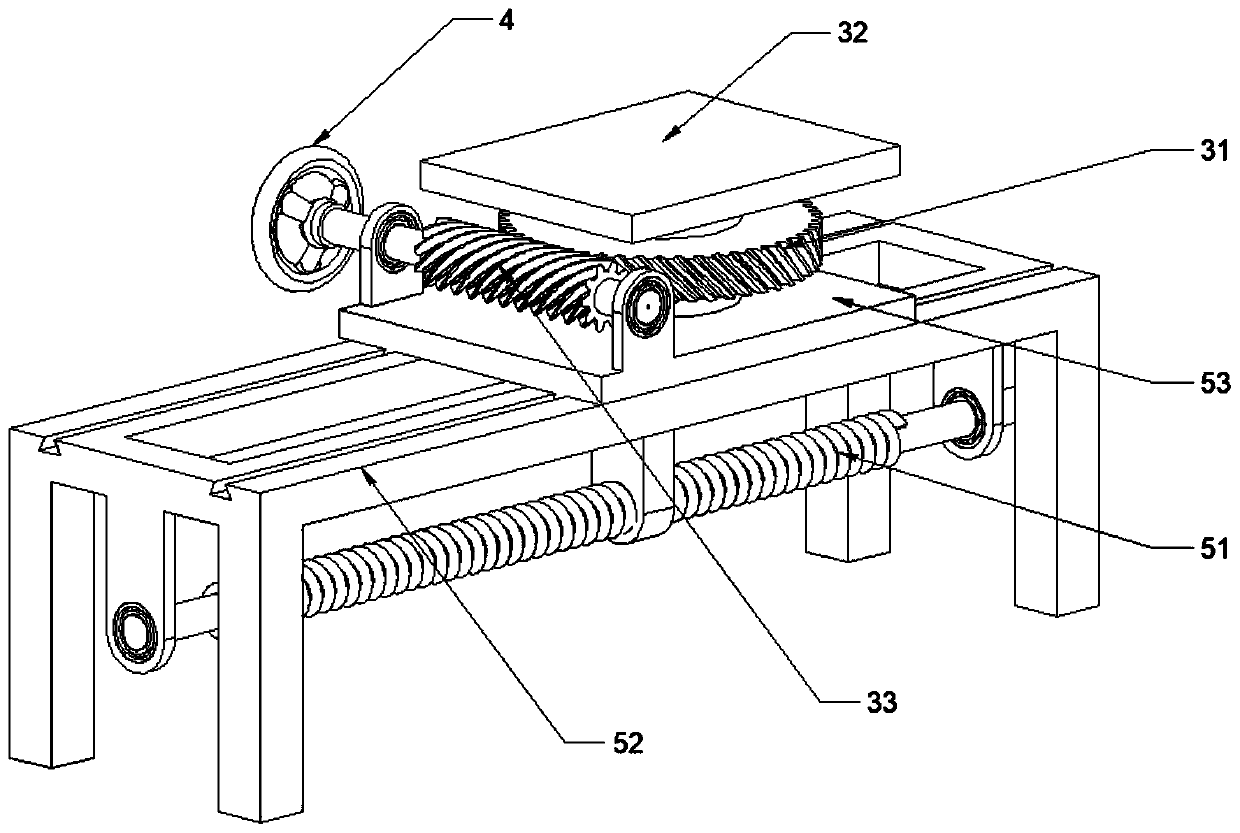

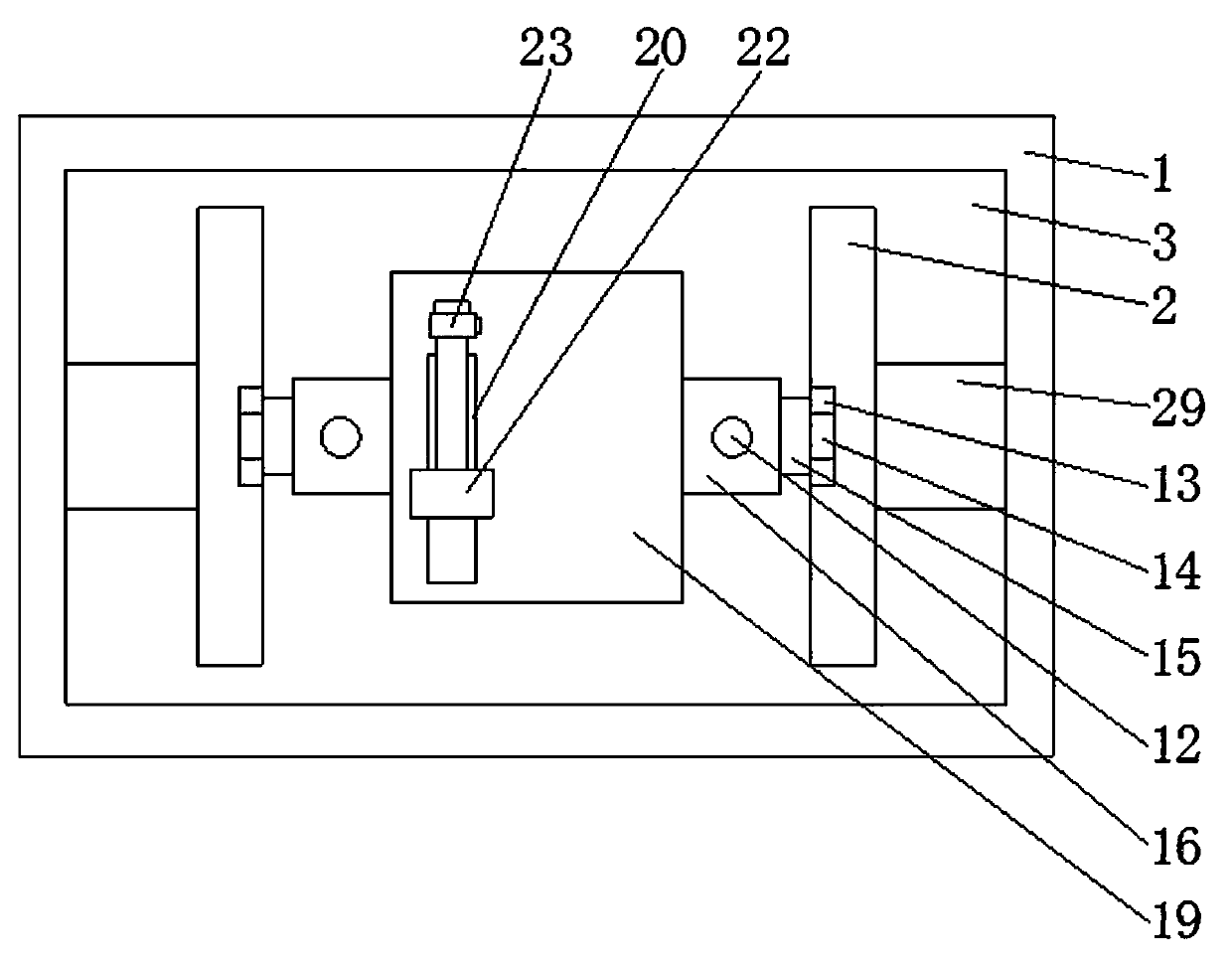

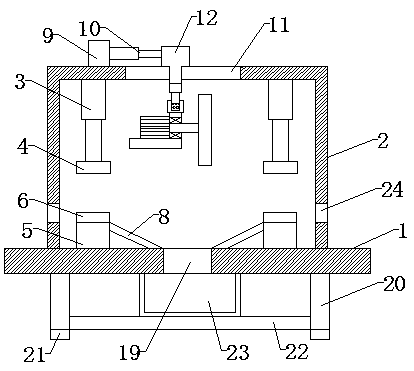

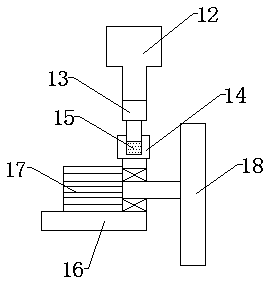

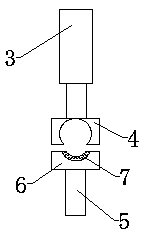

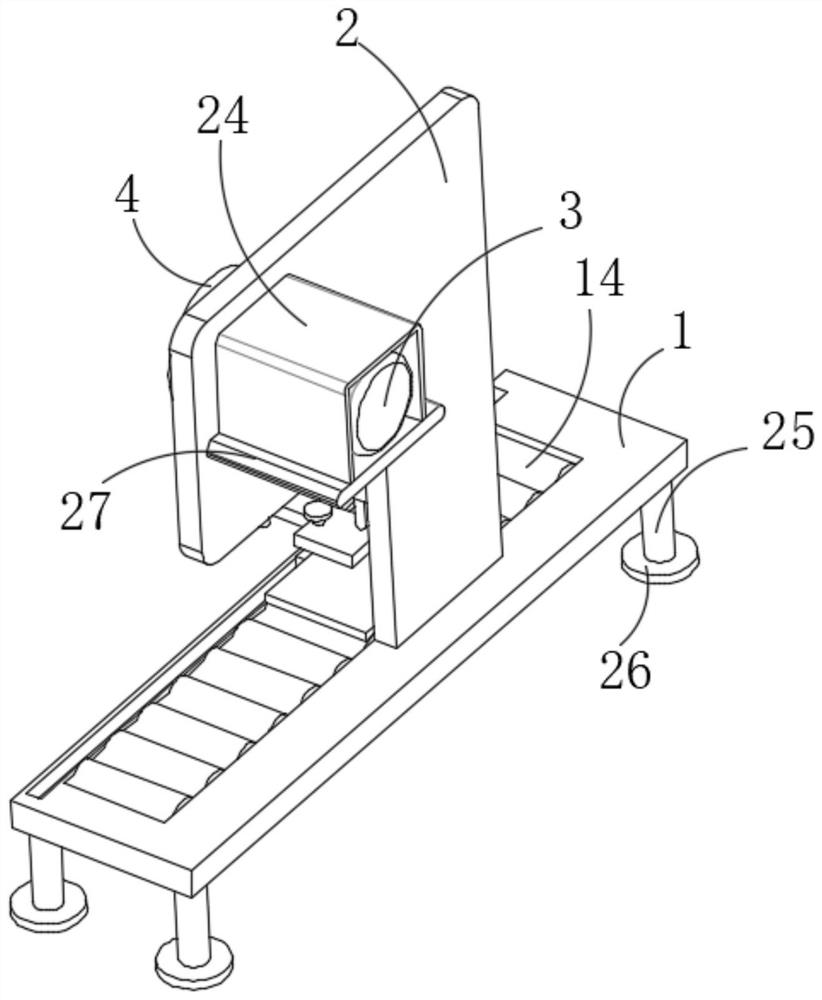

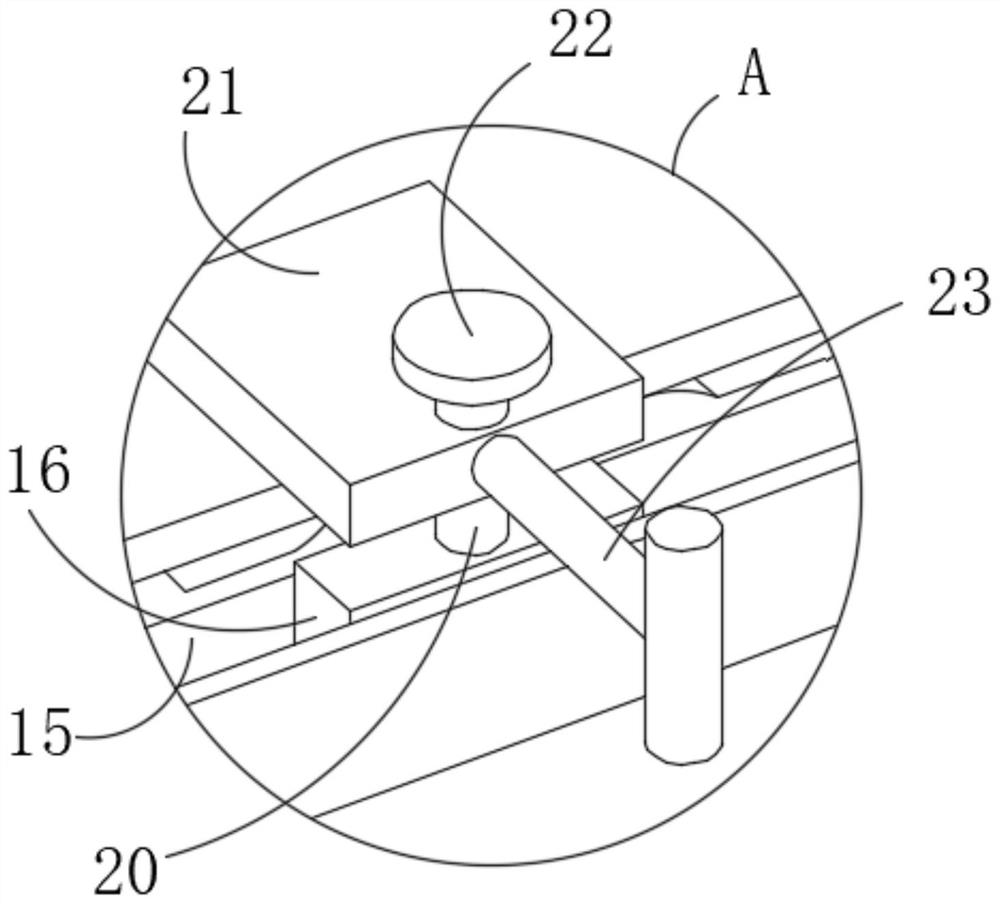

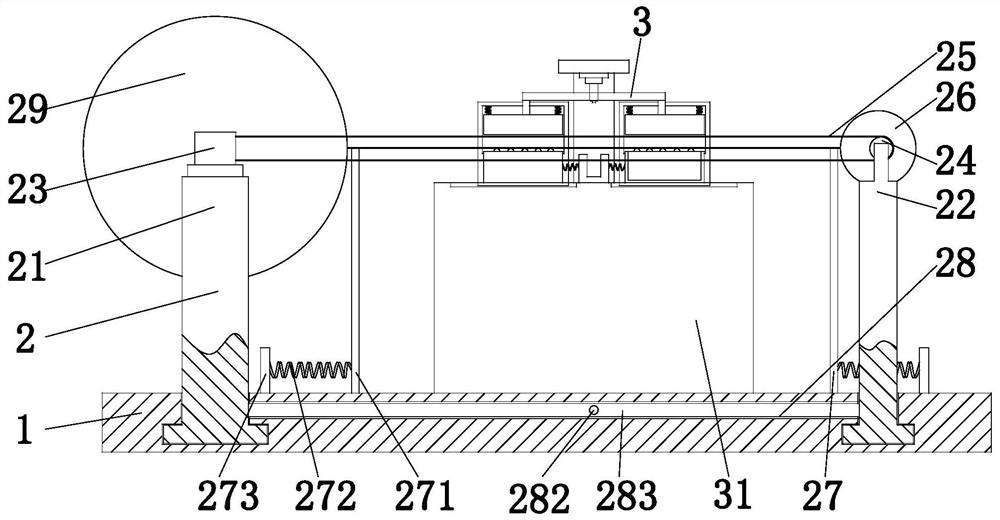

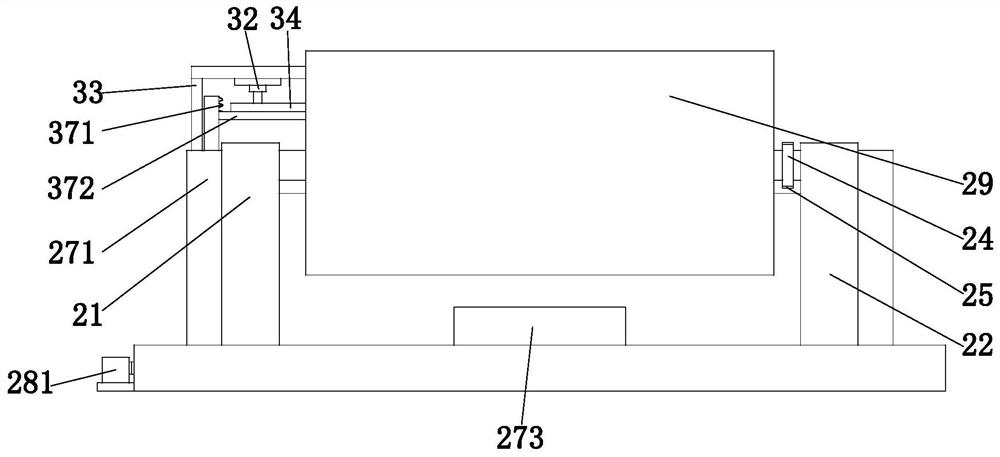

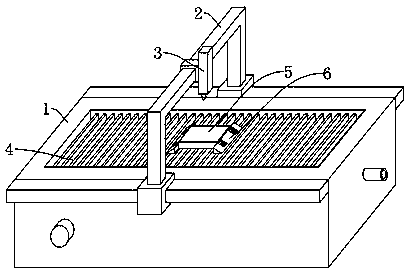

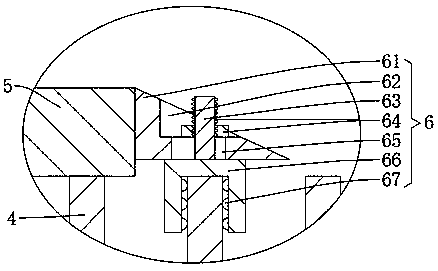

Decorative aluminum plate producing, manufacturing and cutting machining machine and machining method

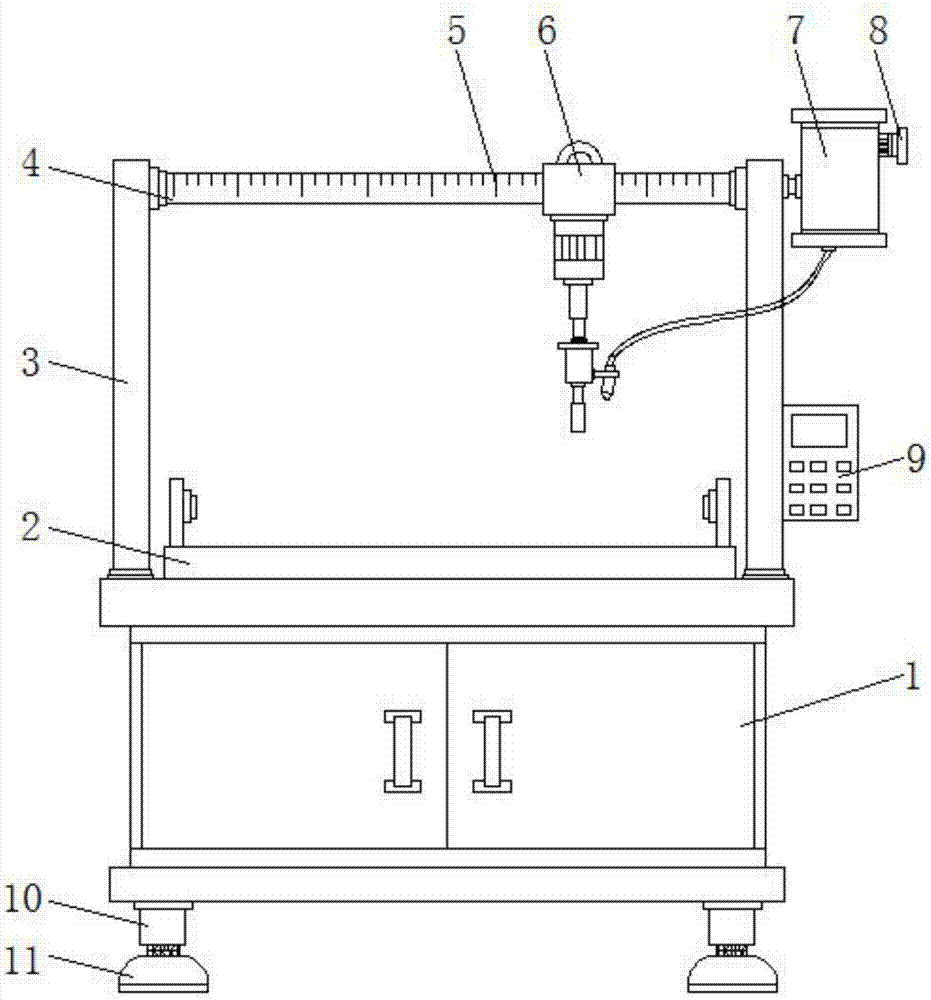

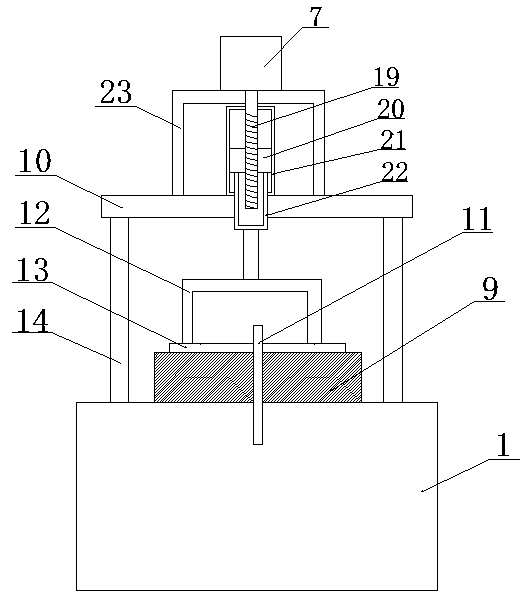

InactiveCN113182877AHigh precisionAvoid affecting the cutting effectMeasurement/indication equipmentsOther manufacturing equipments/toolsMachiningWorkbench

The invention relates to a decorative aluminum plate producing, manufacturing and cutting machining machine and a machining method. The decorative aluminum plate producing, manufacturing and cutting machining machine comprises a workbench, a fixing device and a cutting device, the fixing device is arranged at the top of the workbench, and the cutting device is arranged at the position, close to the right side, of the top of the workbench and located above the fixing device. According to the decorative aluminum plate producing, manufacturing and cutting machining machine and the machining method, through cooperation of the workbench, the fixing device and the cutting device, a decorative aluminum plate needing to be cut and machined is placed on the fixing device firstly, the decorative aluminum plate is moved to the proper cutting position through the fixing device, and the precision of cutting the decorative aluminum plate by the machine is improved; and after the cutting position is adjusted, the cutting edge of the decorative aluminum plate needing to be cut is clamped and fixed through the fixing device, the situation that the decorative aluminum plate generates the edge warping phenomenon in the cutting process, and the cutting effect is influenced is prevented, and finally the decorative aluminum plate is ground after being cut through the cutting device.

Owner:滕阳

Cutting and clamping device capable of cutting based on rotation and ensuring ordered notches

The invention relates to the technical field of ocean engineering and discloses a cutting and clamping device capable of cutting based on rotation and ensuring ordered notches. The cutting and clamping device comprises a rotary table, wherein a rotary shaft is movably connected into the rotary table; the rotary shaft rotates to drive the rotary table to rotate synchronously; a gear is movably connected with the outer side of the rotary shaft; a first connecting rod moves to drive a vertical rod to move synchronously; the side, far away from the gear, of the first connecting rod is movably connected with the vertical rod; through cooperative application of a connecting block and the rotary table, a cable is cut; the rotary speed of the rotary table keeps constant, so that the cable cuttinglength keeps constant; through cooperative application of a third connecting rod and a limiting clamp, the cable is clamped during the cutting process, so that the cable stability is ensured during the cutting process, and the cable is prevented from being cut irregularly; and through cooperative application of the gear and a sliding block, the limiting clamp is driven to move, so that the linkageof the entire cutting and clamping device is improved, and the operation is simpler.

Owner:汤苏花

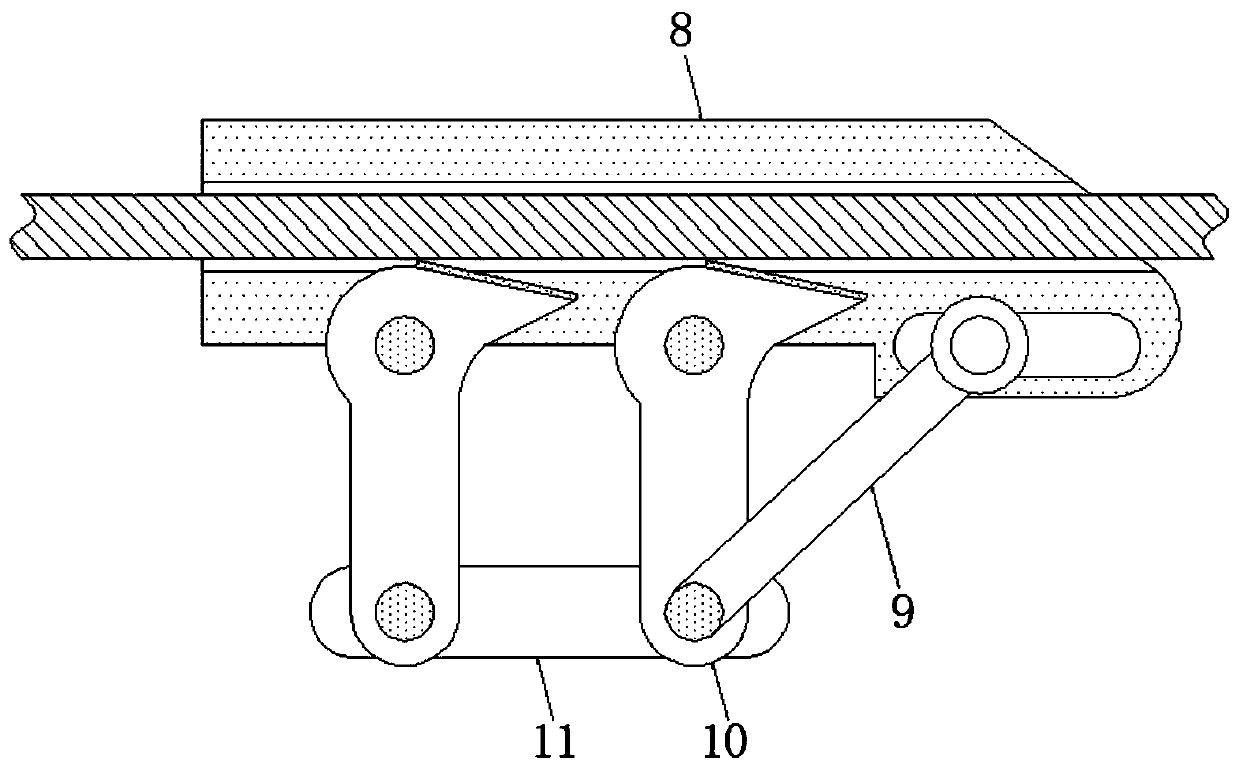

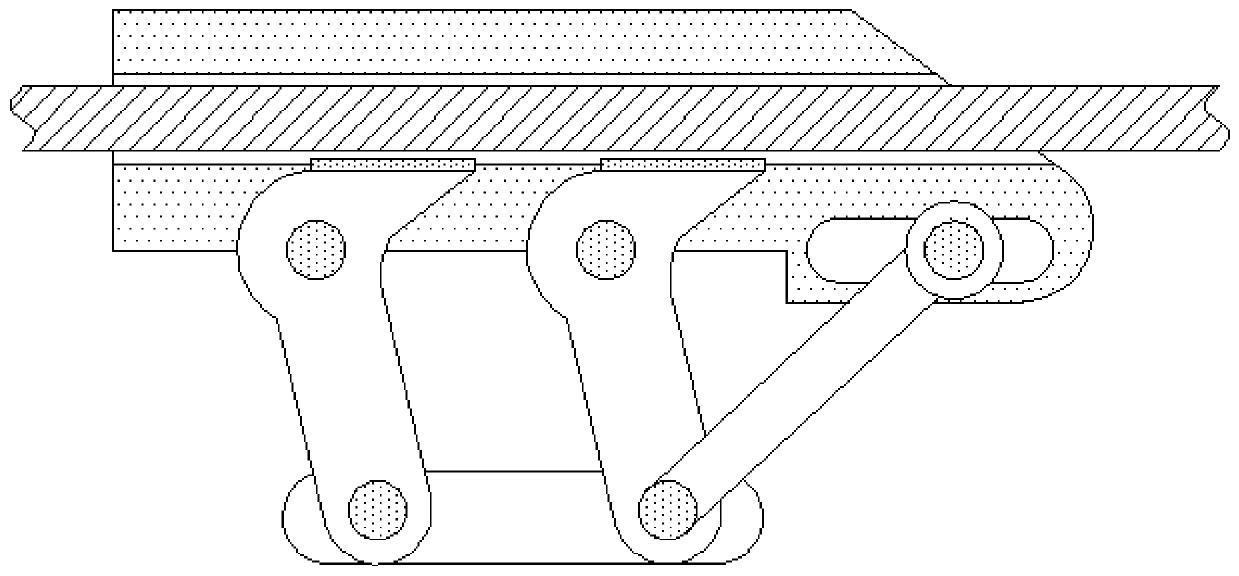

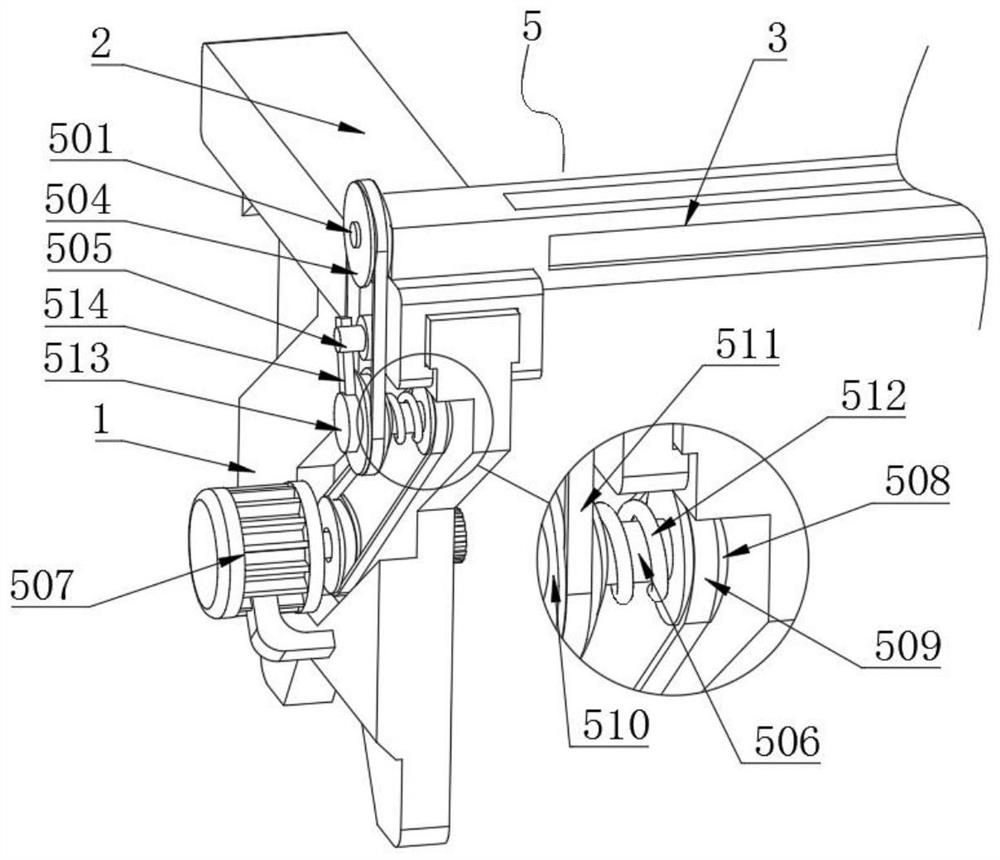

Cutting machine with pressing block mechanism

ActiveCN107081811AImprove tool change efficiencyAccelerateMetal working apparatusEngineeringMechanical engineering

The invention discloses a cutting machine with a pressing block mechanism. The cutting machine comprises an upper machine frame, a left machine frame and a right machine frame. The upper machine frame is provided with a cutting mechanism which can move on the upper machine frame left and right through a drive mechanism. A cutting workbench is further arranged between the left machine frame and the right machine frame, and comprises conveying rollers arranged at the front end and the rear end. A conveying belt is arranged on the conveying rollers at the front end and the rear end. At least three sets of pressing block holders are evenly distributed at the left end and the right end of the conveying belt. Press fitting table boards are arranged between the pressing block holders and at the lower end of an upper conveying belt section. The pressing block holders are provided with air cylinders, and a pressing block is arranged between every two air cylinders at the left end and the right end. Through arrangement of the pressing block mechanism, the pressing block mechanism can be pressed down when cutting is needed so as to press to-be-cut materials, and accordingly, the situation that materials shift and consequently the cutting effect is affected is avoided.

Owner:HONGCHENG SCI & TECH LTD

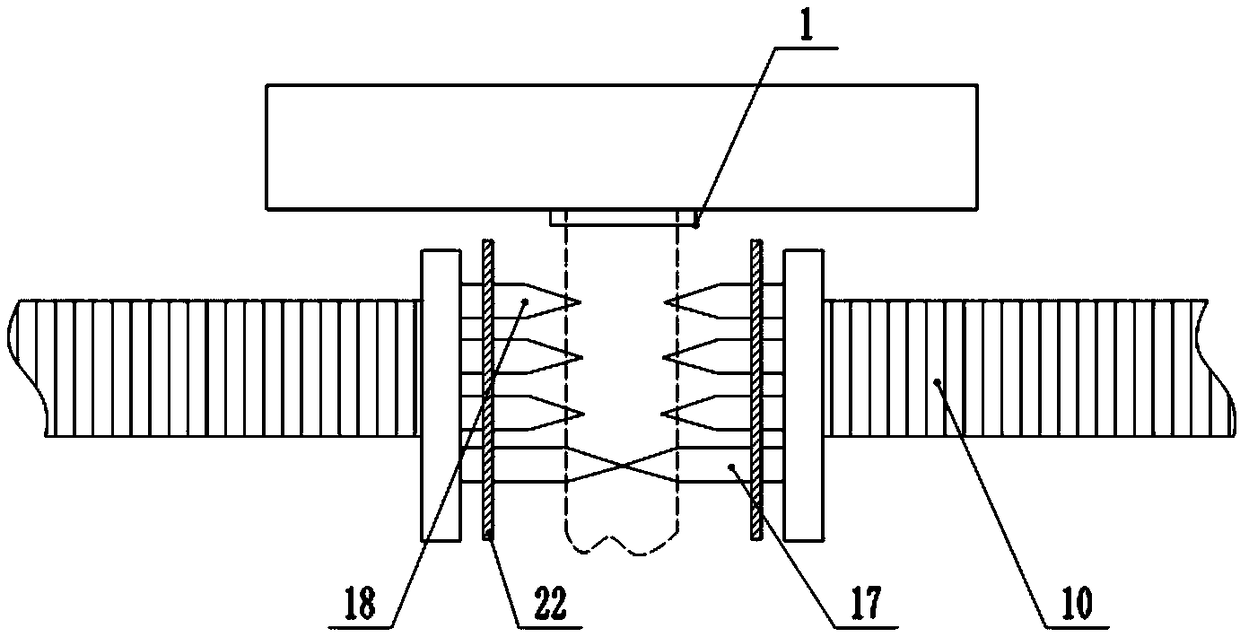

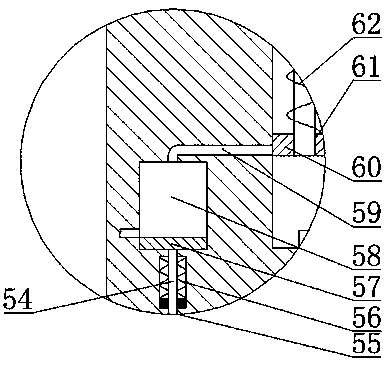

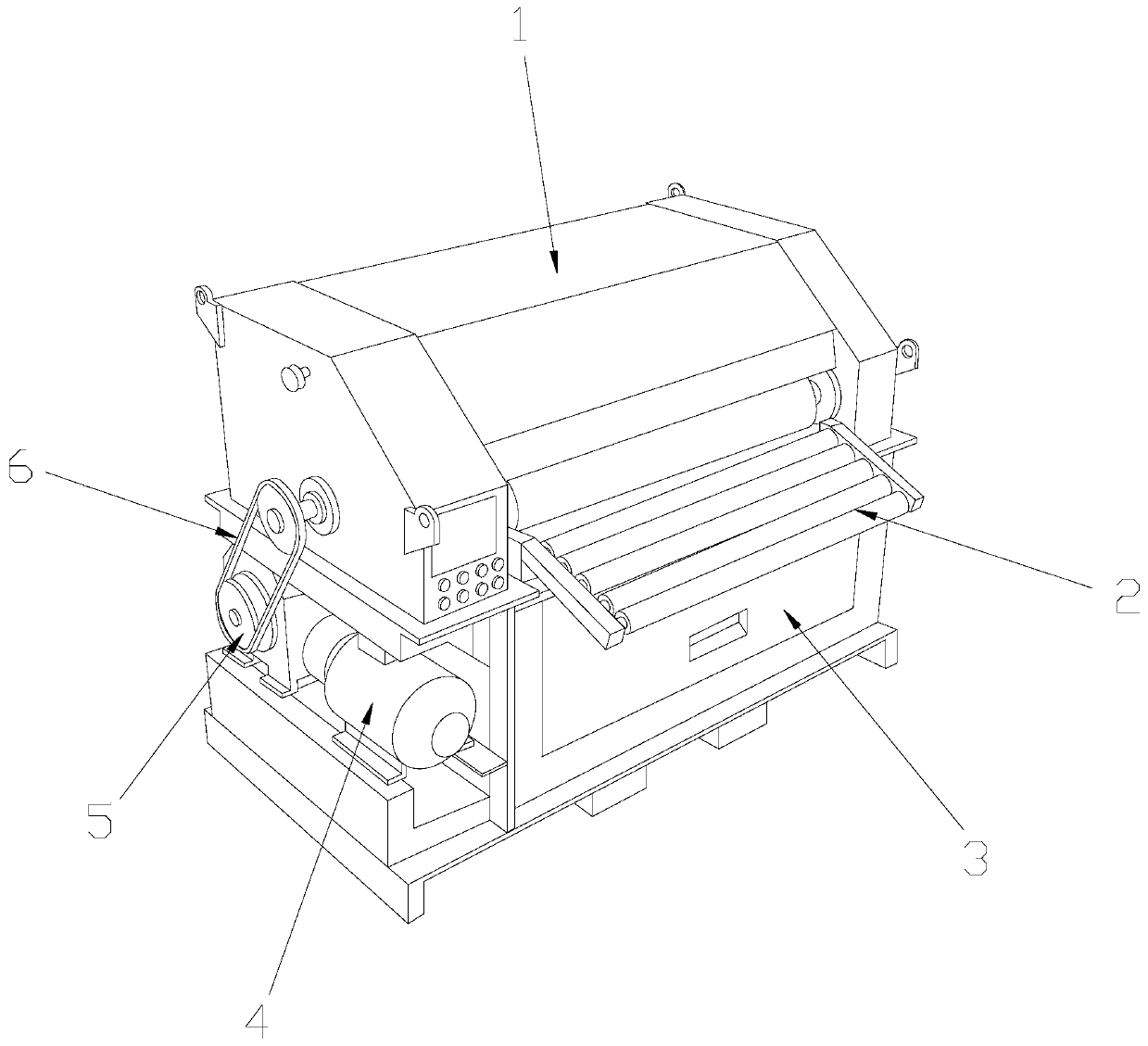

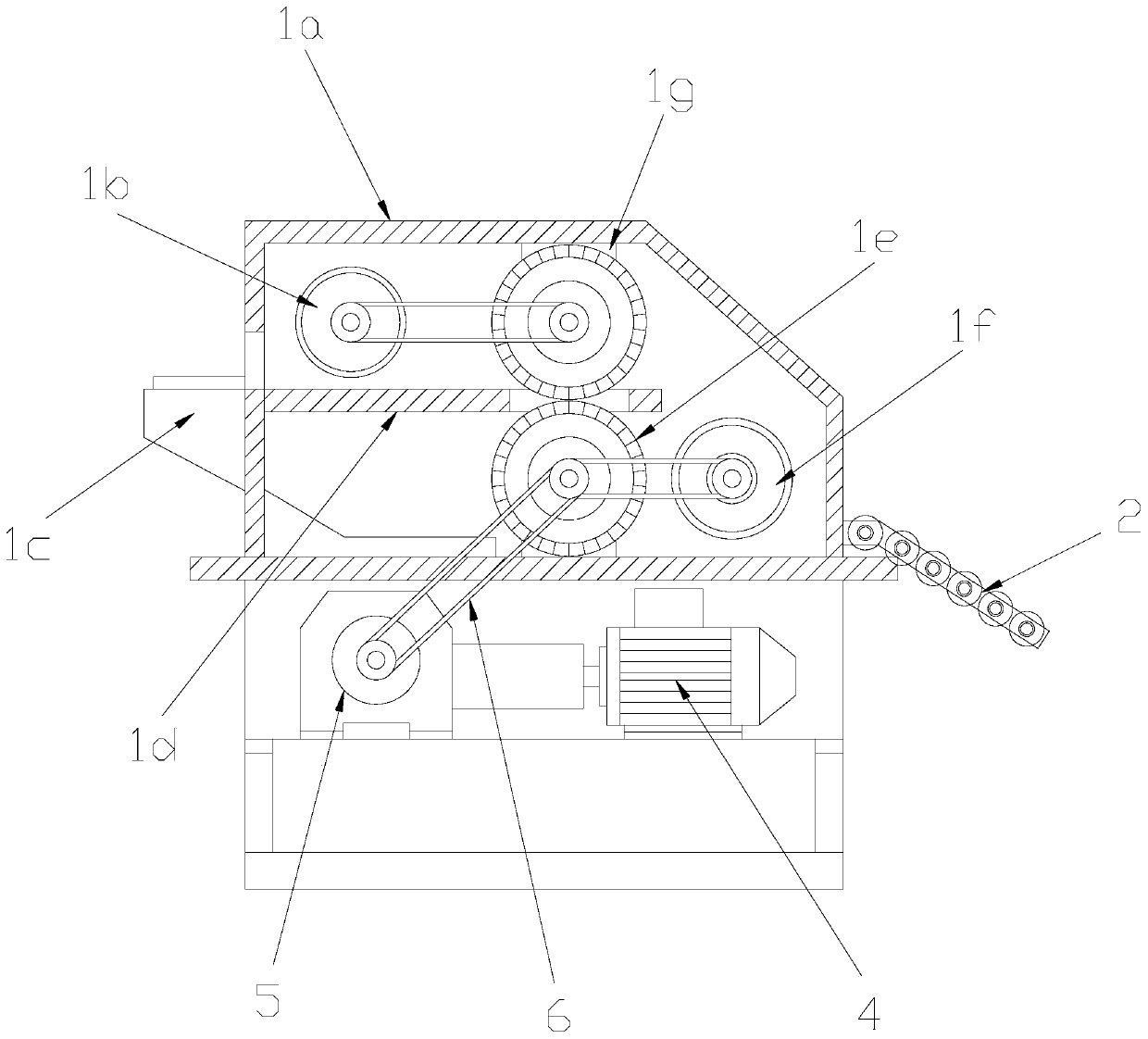

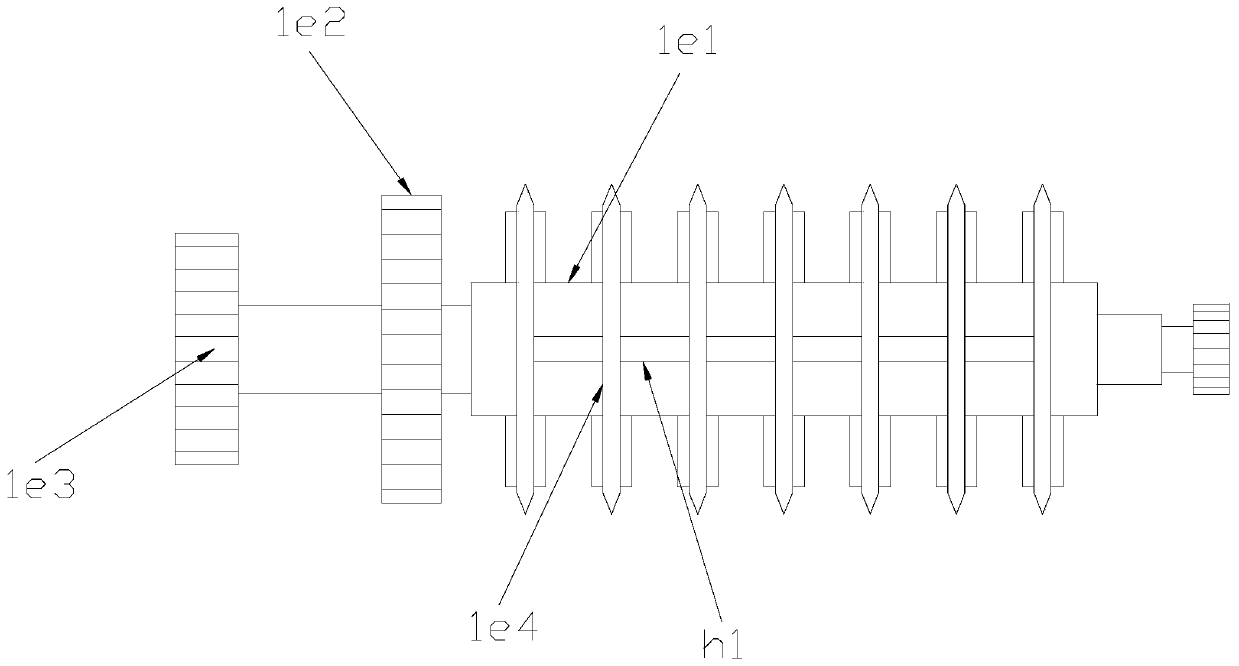

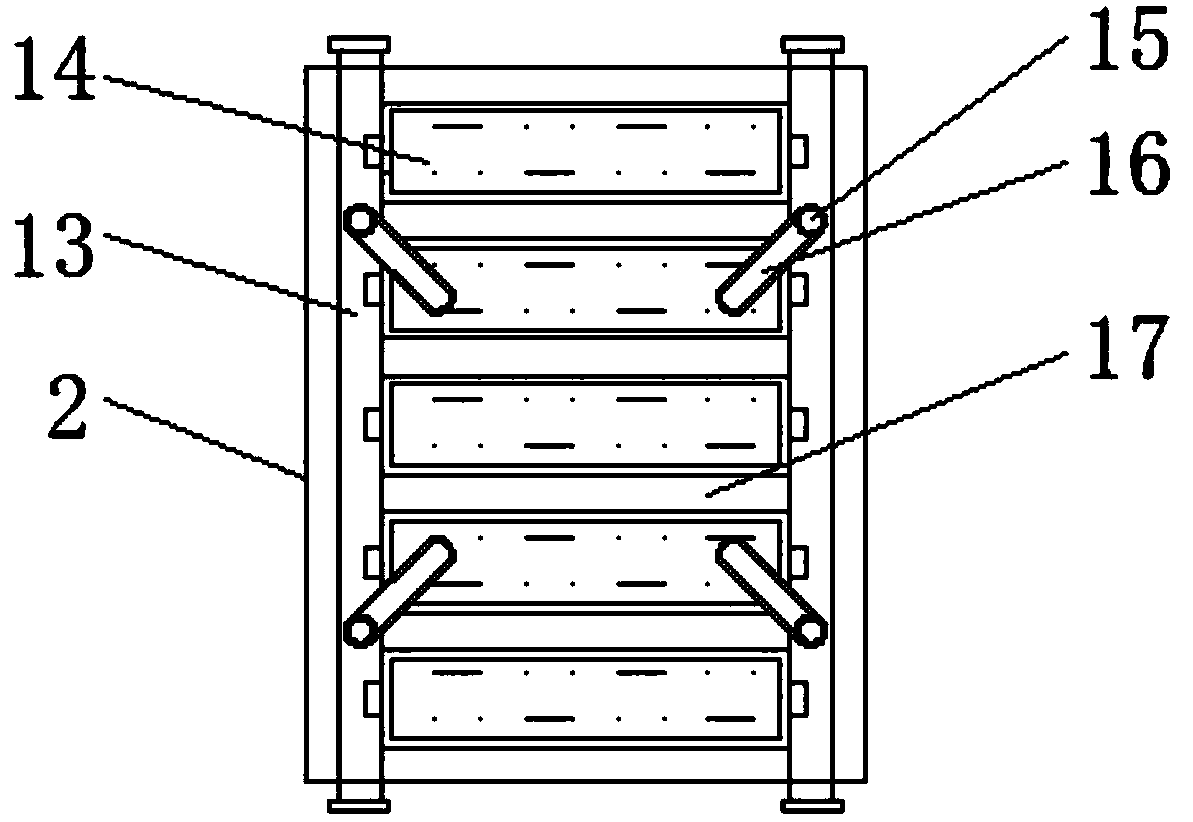

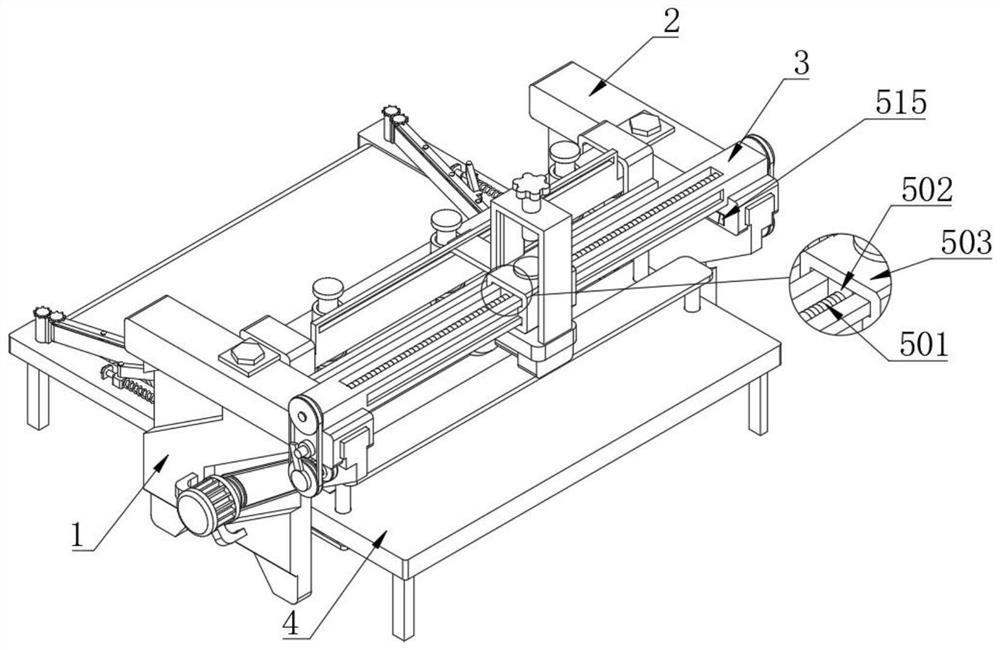

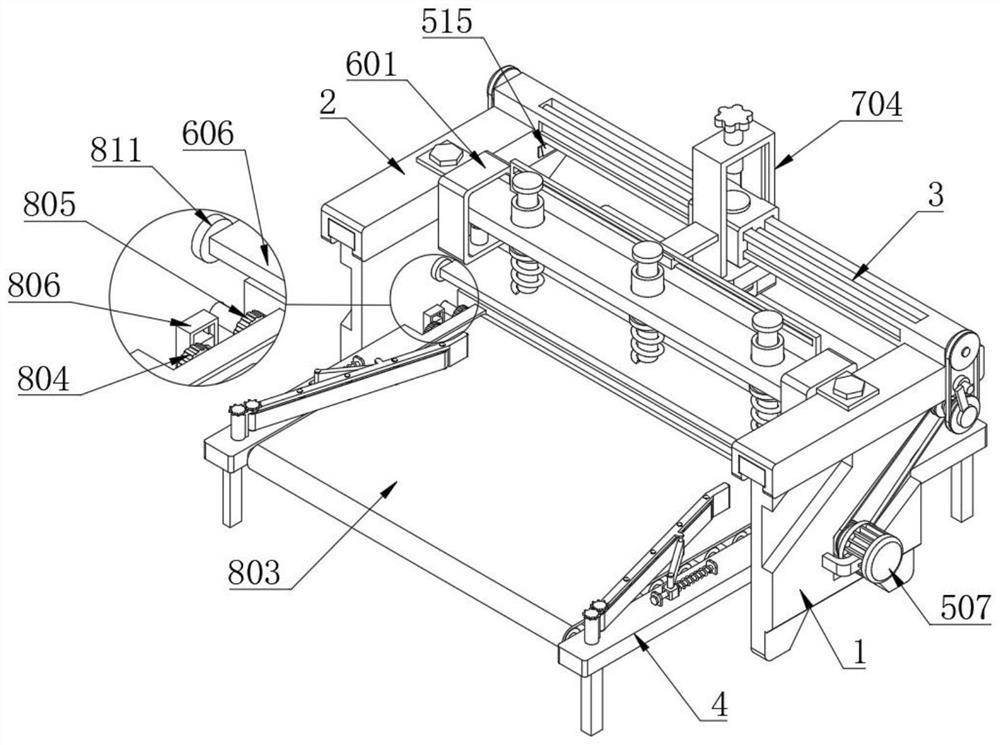

Special rubber processing equipment

ActiveCN111185960AShorten or lengthen the distanceAvoid affecting the cutting effectMetal working apparatusKnife bladesIndustrial engineering

The invention discloses special rubber processing equipment. The special rubber processing equipment structurally comprises a rubber canvas strip cutting machine, a roller receiver, a waste chip recovery box, an engine, a gearbox and a transmission chain, wherein the rubber canvas strip cutting machine feeds rubber canvas into a workbench for cutting through guide rollers, a size-adjustable cutting mechanism cuts the rubber canvas into strips at the same time by using a plurality of cutting blades, the rubber canvas is cut into a plurality of strips at a time, the distance among the cutting blades is controlled to be shortened or lengthened through a first rotary cap, the width of the cut rubber canvas strips is changed, the working flexibility is improved, the cutting blades press the rubber canvas through an auxiliary abutting plates, the rubber canvas is prevented from shaking to affect the strip cutting effect during strip cutting, the cutting blades are automatically ground by using a grindstone, the working efficiency is improved, operation is easy, according to the design, the cutting blades do not need to be detached for the grinding, and manual grinding is also not needed.

Owner:四川道弘新材料有限公司

Food packaging bag cutting equipment

InactiveCN112223364AAffect the cutting effectAvoid wastingBag making operationsPaper-makingAgricultural engineeringStructural engineering

The invention relates to the technical field of food packaging bags, and discloses food packaging bag cutting equipment which comprises a bottom plate. A fixing frame is fixedly connected to the top of the bottom plate, a base plate is horizontally arranged in the fixing frame, the base plate is fixedly connected with the top of the bottom plate, and a flattening mechanism is arranged above the bottom plate. A fixing mechanism is arranged on the left side of the inner wall of the fixing frame, and a cutting mechanism is arranged on the upper portion of the inner part of the fixing frame. By pulling a pull ring, the pull ring drives a pressing block and a rubber pad to move upwards through an inserting rod, after one end of a food packaging bag is placed at the bottom of the rubber pad, byloosening the pull ring, the food packaging bag can be extruded and fixed under the elastic action of springs, the situation that the cutting effect on the food packaging bag is affected due to movingof the food packaging bag during cutting is effectively avoided, waste of the food packaging bag is avoided, and the cutting quality of the food packaging bag is guaranteed.

Owner:浙江时进包装有限公司

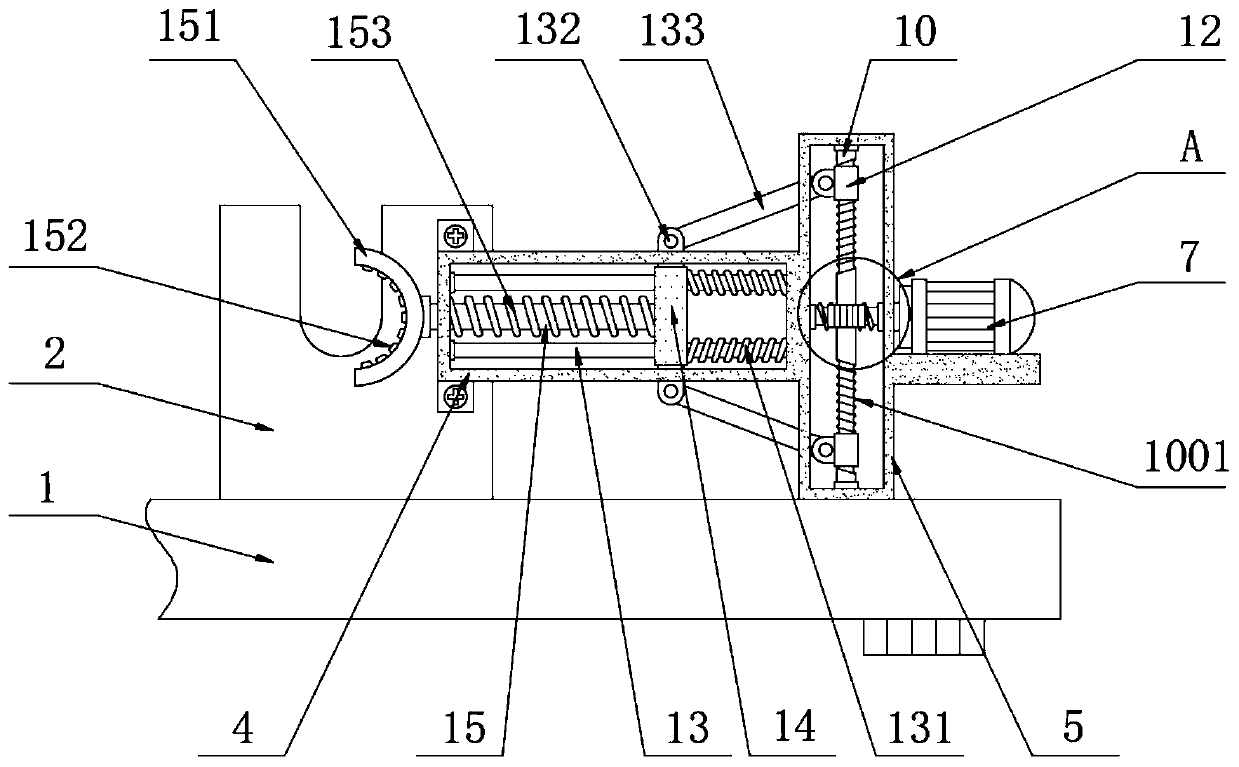

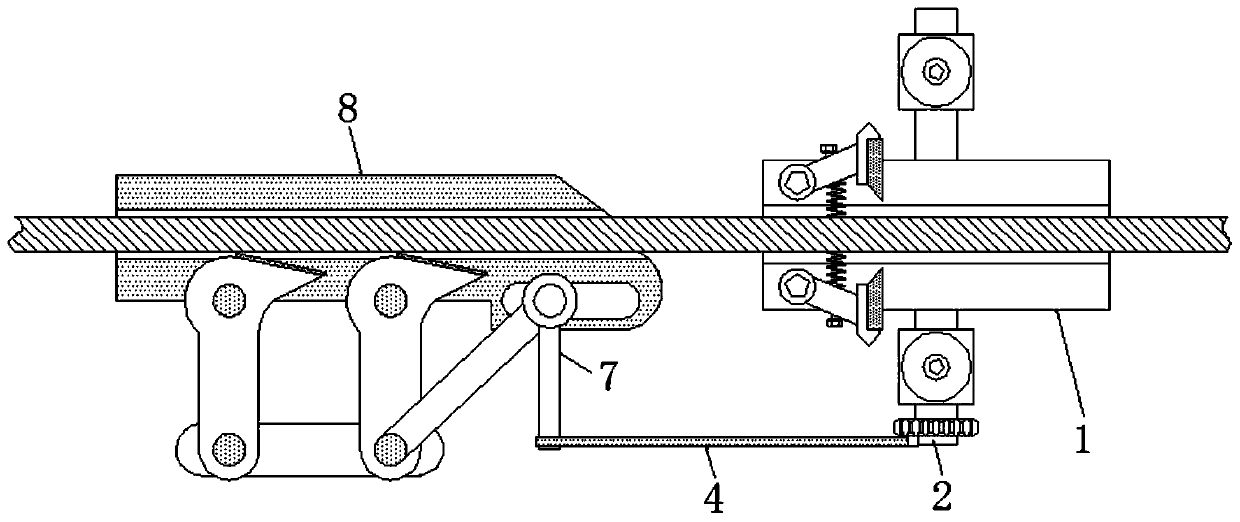

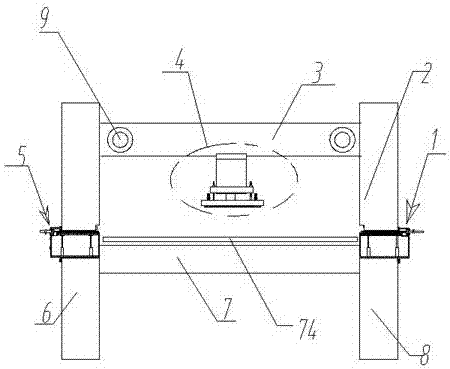

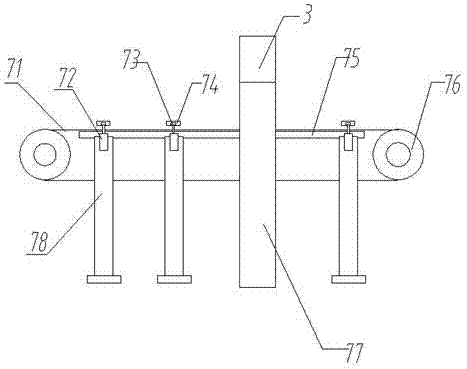

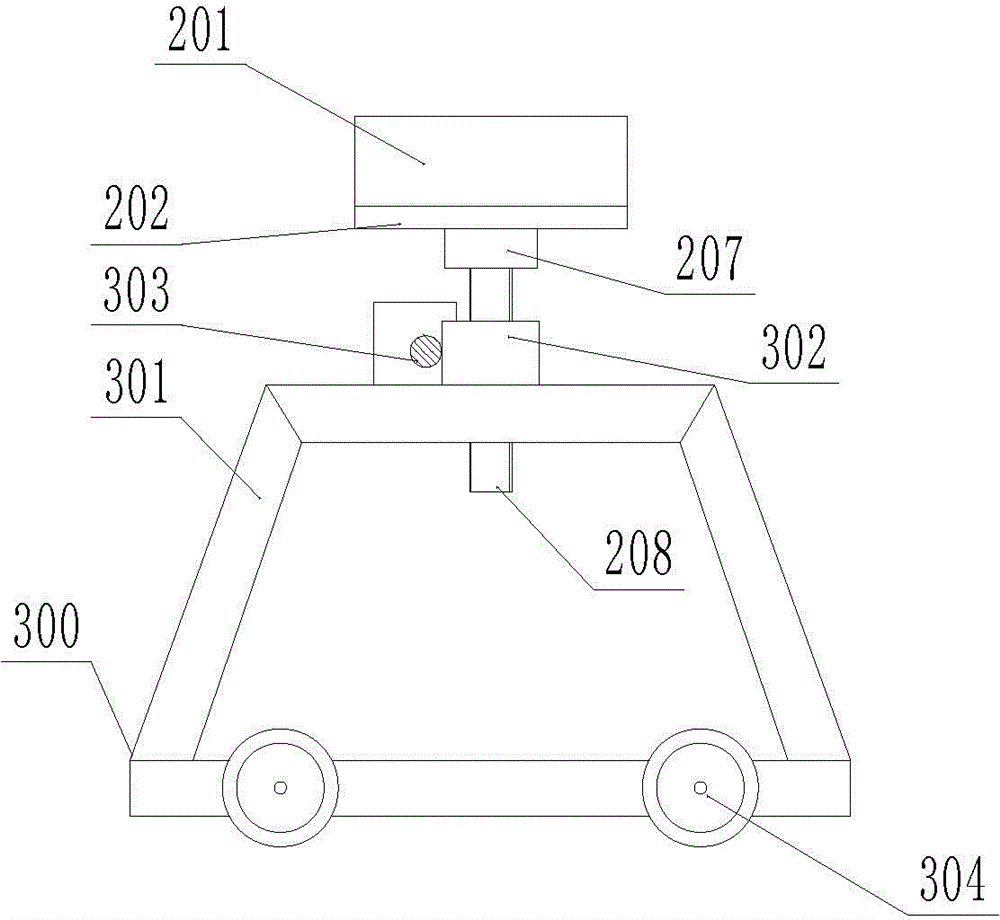

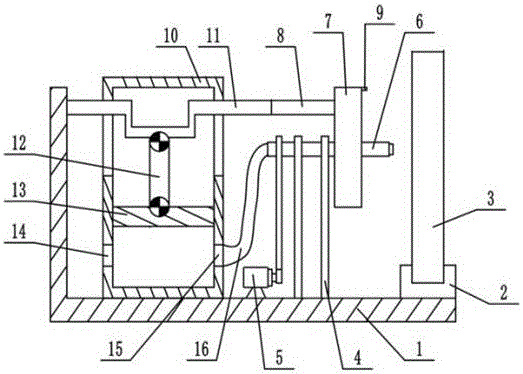

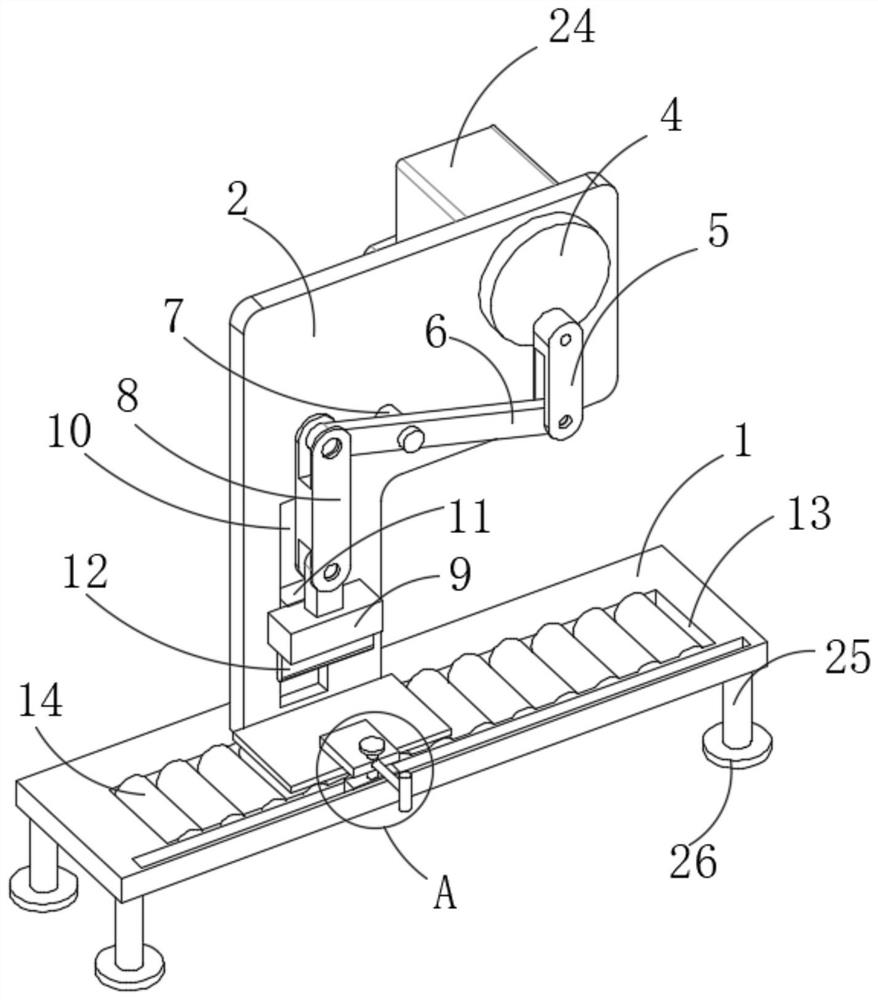

Feeding car for sawing machine

InactiveCN104385036AAvoid affecting the cutting effectMetal sawing accessoriesMetal working apparatusAgricultural engineeringThreaded rod

The invention discloses a feeding car for a sawing machine. In order to overcome the defects that height adjustment is difficult and bar handling efficiency is low by adopting the existing sawing machine support frame, the invention provides the feeding car for the sawing machine. The feeding car for the sawing machine comprises a support frame and a material shelf; the material shelf is located above the support frame; the material shelf comprises a material bottom plate, a material fixed baffle, a material movable baffle and a threaded pore plate; the material movable baffle is located between the material fixed baffle and the threaded pore plate; a threaded rod is arranged between the material movable baffle and the threaded pore plate; the bottom part of the material bottom plate is provided with a sleeve; a threaded shaft is arranged between the support frame and the material shelf; the sleeve is sheathed with the threaded shaft; the support frame comprises a support framework; the upper part of the support framework is provided with two worm support plates; a worm is arranged between the two worm support plates; the upper part of the support framework is also provided with a worm gear; a threaded hole is formed in the middle part of the worm gear; the worm gear is in threaded connection with the threaded shaft; the worm is meshed with the worm gear.

Owner:CHONGQING SHUAICHANG MACHINE MFG

Intelligent high-speed laser cutting machine control system

InactiveCN108436307AAvoid accumulationEasy to moveWelding/cutting auxillary devicesAuxillary welding devicesIntelligent lightingMachine control

The invention discloses an intelligent high-speed laser cutting machine control system which comprises a machine body, a control display screen and a wind opening. A machine tool is arranged above themachine body. Supporting rods are installed on the two sides of the machine tool. A cross beam is fixed onto the supporting rods. A supporting arm is arranged above the cross beam. A laser cutting head is installed at the lower end of the supporting arm. The control display screen is arranged on the right of the machine body. An installing support is fixed below the control display screen. Sliding blocks are installed at the lower ends of the supporting rods. Sliding rails are arranged on the left sides of the sliding blocks. Limiting plates are installed at the lower ends of the sliding blocks. A fixing base is fixed to the bottom of the machine body. Pipelines are installed on the left side and the right side below the machine tool. A water tank is arranged in the machine tool. A movingshaft is installed above the right of the machine tool. The intelligent high-speed laser cutting machine control system is provided with a fan, dust generated by cutting can be sucked into a dust collecting groove, and the influence on the body of a user from the dust is avoided.

Owner:盐城市雷鸣电器制造有限公司

Anti-collision induction device for profile laser cutting and control method thereof

PendingCN112192035AAvoid damageEasy to assemble and disassembleLaser beam welding apparatusPhysicsLaser cutting

The invention discloses an anti-collision induction device for profile laser cutting. The anti-collision induction device comprises a laser cutting head body. A control method of the anti-collision induction device for profile laser cutting comprises a step of separately inserting two rectangular clamping blocks into two rectangular clamping grooves in a U-shaped protection plate. According to theanti-collision induction device for profile laser cutting and the control method thereof, the rectangular clamping blocks are inserted into the rectangular clamping grooves in the U-shaped protectionplate, so that elastic pieces are in contact with an annular block in an abutting manner. In addition, the laser cutting head body penetrates through a circular through groove in the U-shaped protection plate, so that the position of the U-shaped protection plate is effectively limited, and the dismounting and mounting are convenient. The U-shaped protection plate cooperates with the stainless steel elastic pieces to protect the lower end of the laser cutting head body, and first pressure springs and second pressure springs cooperate with first permanent magnet blocks and second permanent magnet blocks of the same magnetism to provide buffer protection to the laser cutting head body. Therefore, the impact on the cutting effect due to the contact between the U-shaped protection plate and profiles is avoided, and the damage to the laser cutting head body is prevented.

Owner:徐东新

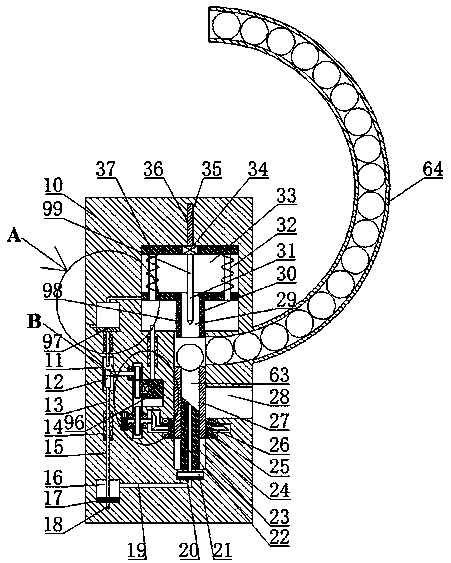

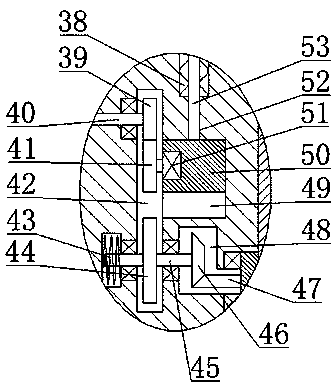

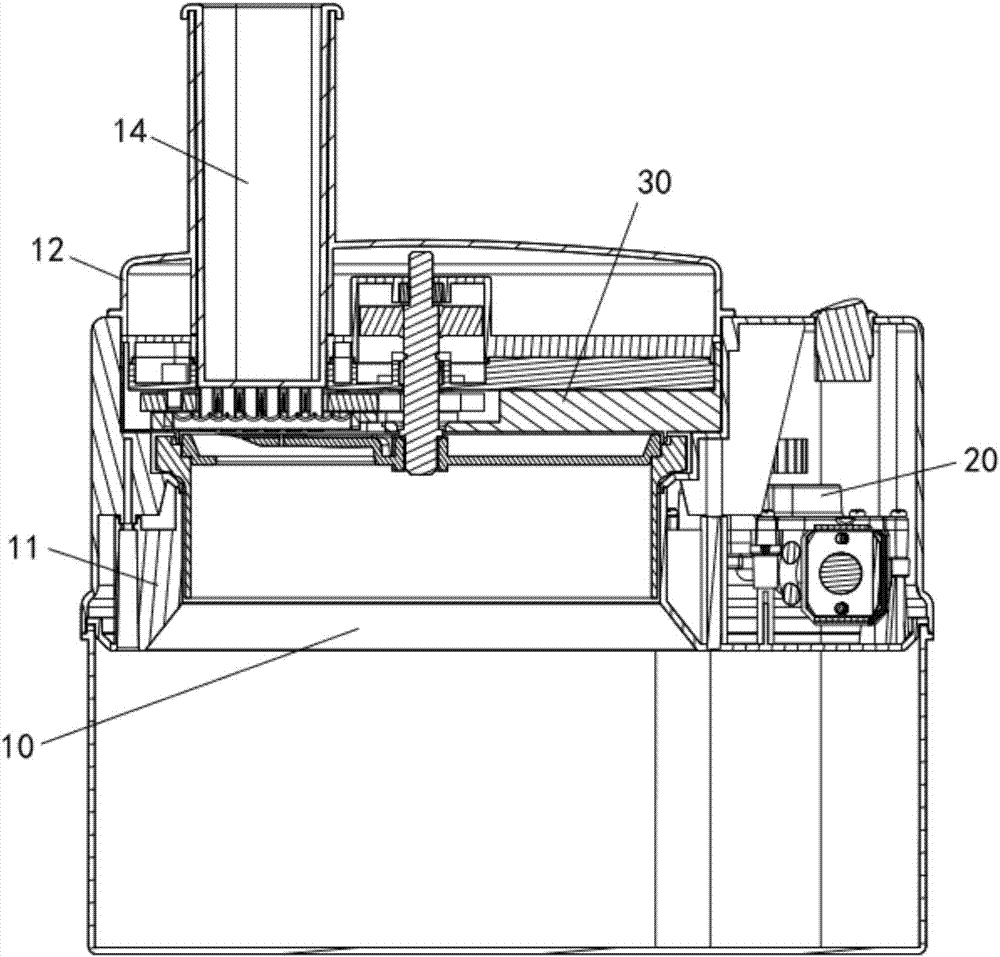

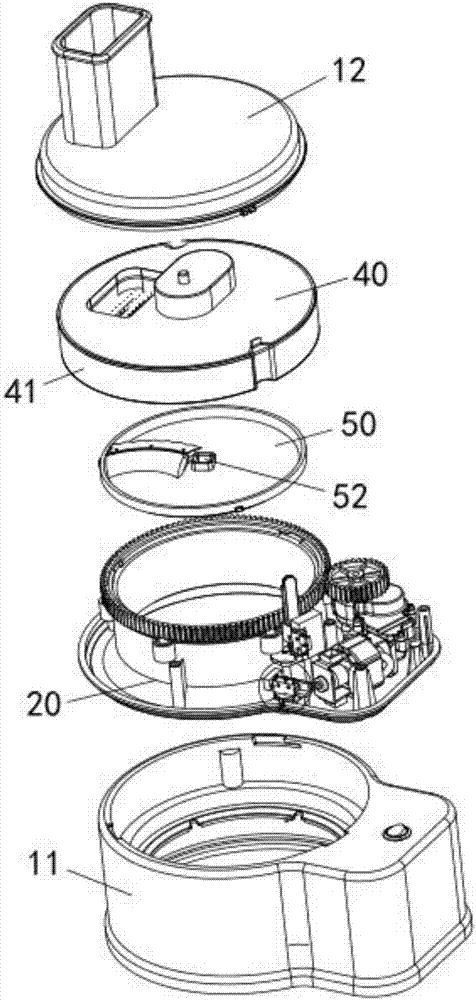

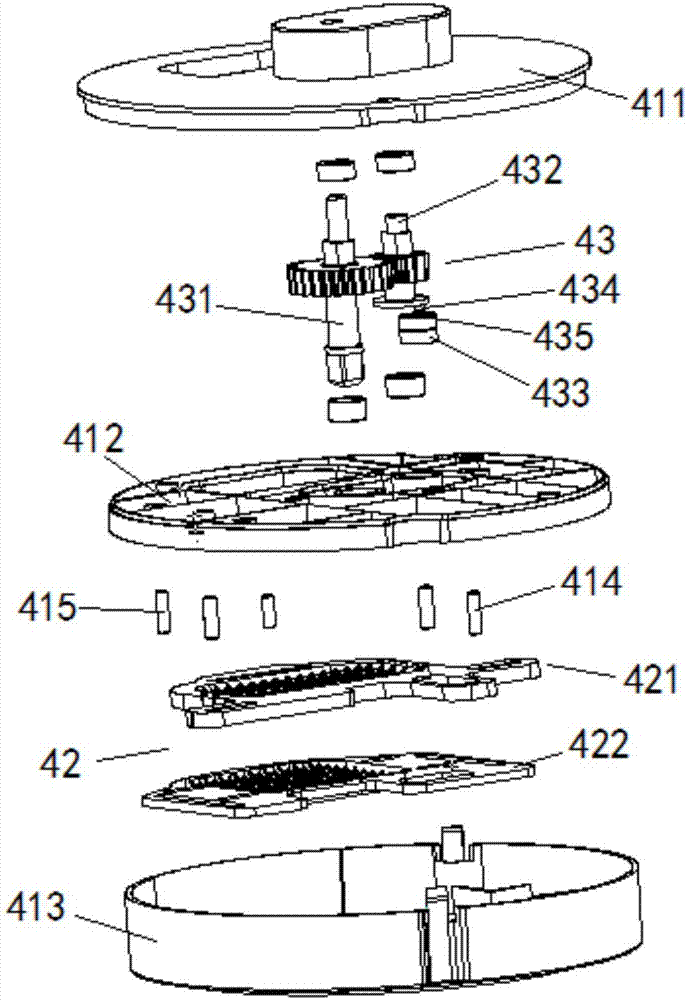

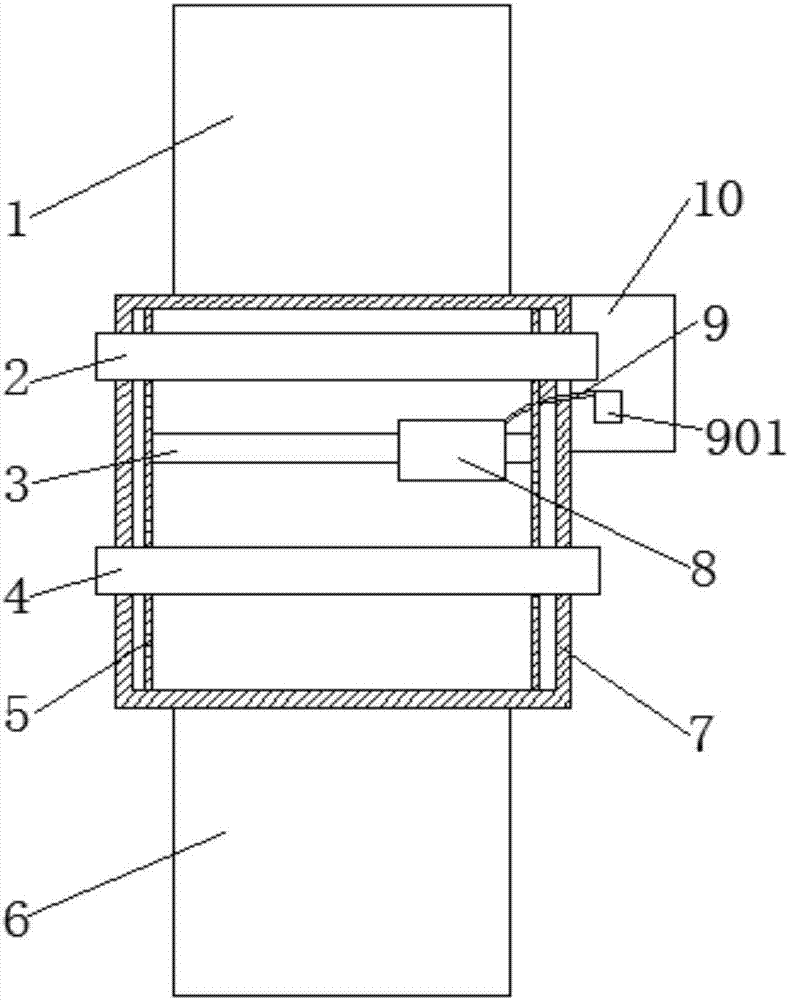

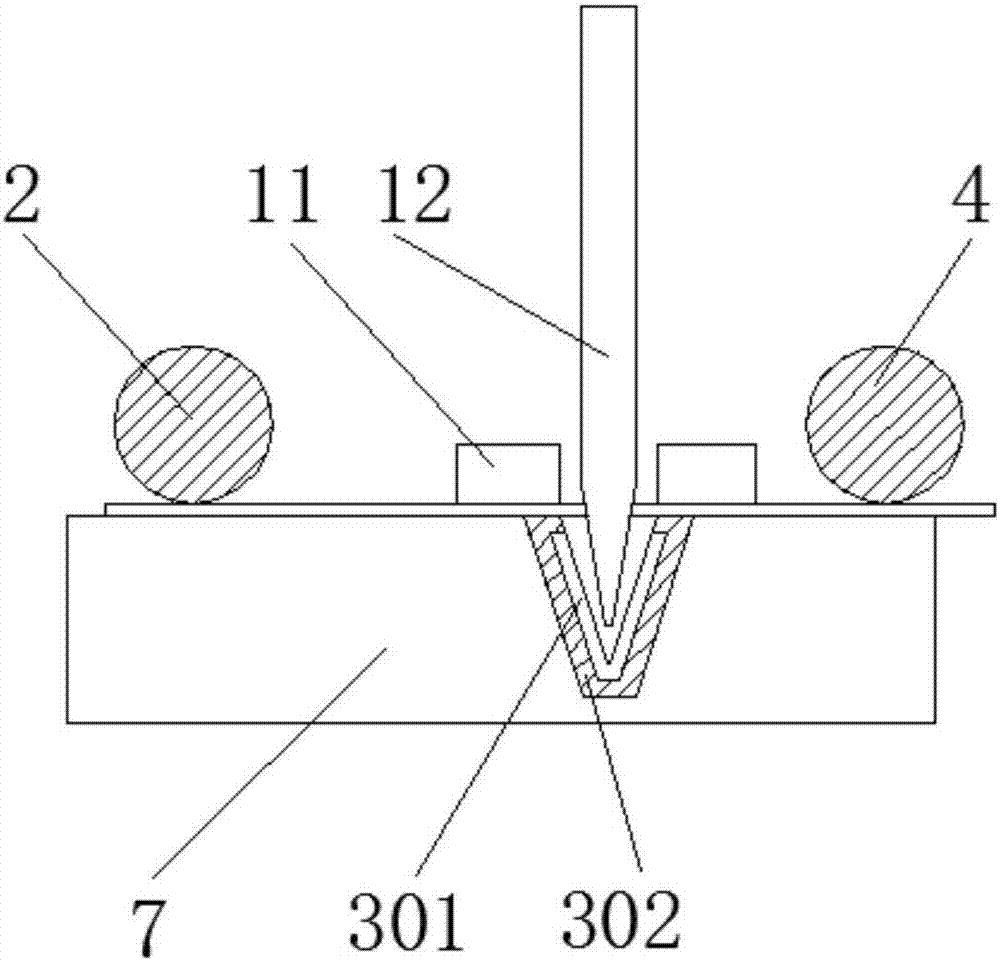

Food processor

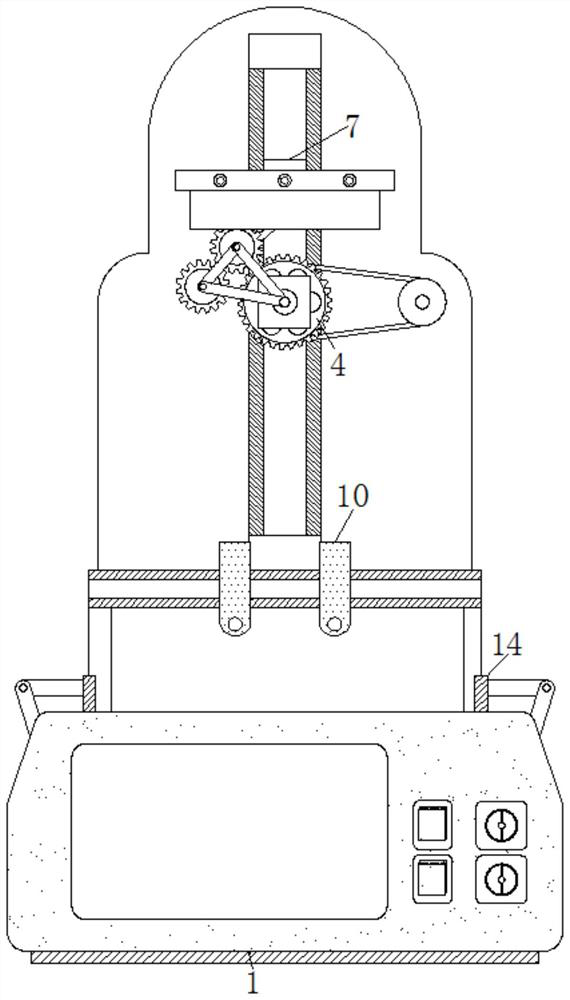

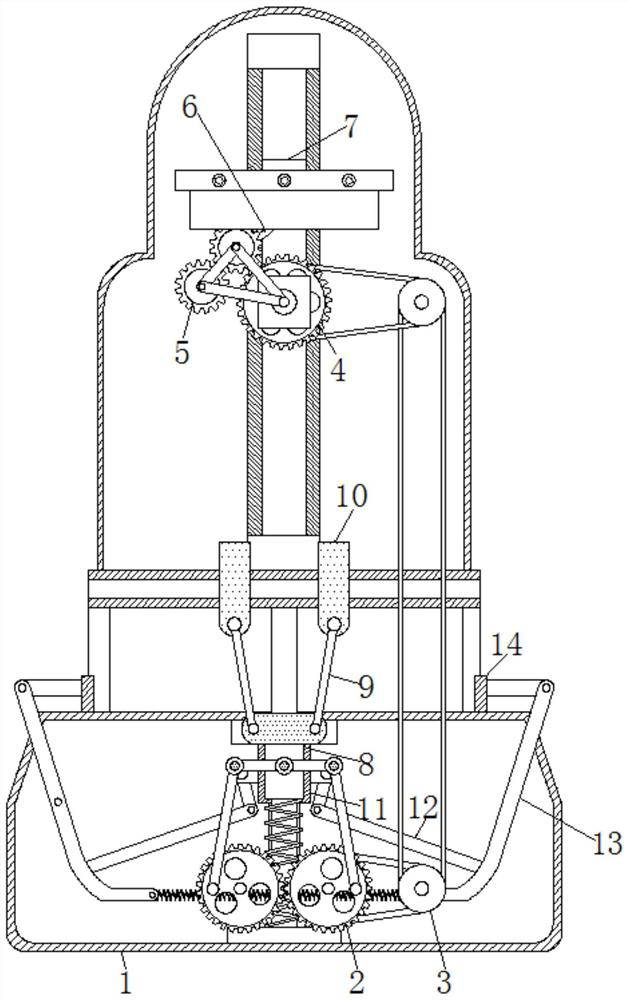

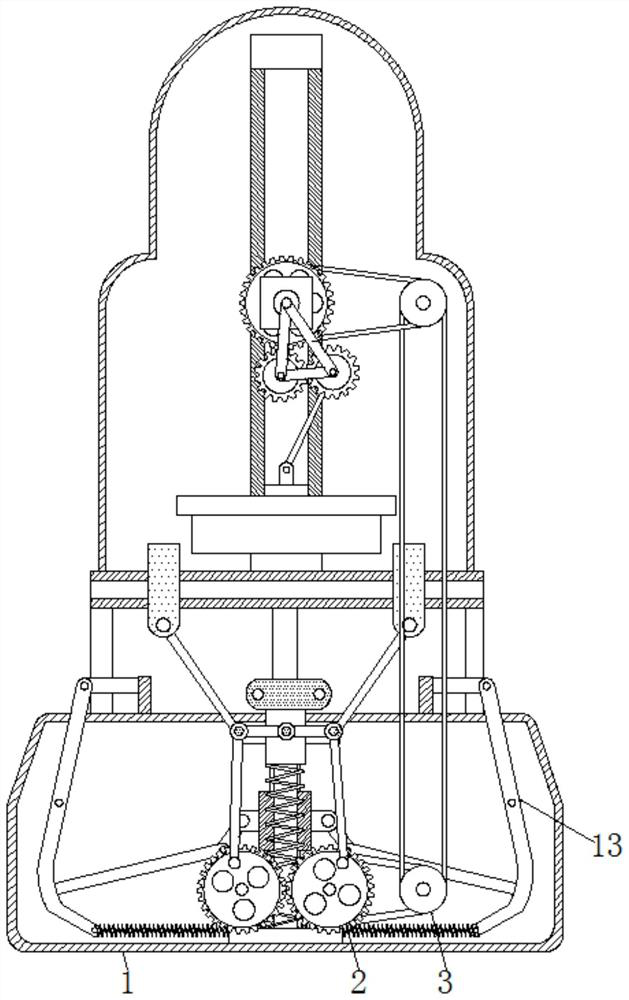

PendingCN106889915AStrong cutting forceStraight line cutting method is reasonableKitchen equipmentReciprocating motionEngineering

The invention relates to the technical field of food processing equipment, in particular to a food processor. The food processor comprises a host with a driving unit, a feed inlet and a discharge outlet are arranged in the host, a processing component in transmission connection with the driving unit is installed in the host and is located between the feed inlet and the discharge outlet, the processing component comprises a cutting module, the cutting module comprises a shell and a cutter component and an eccentric wheel component which are installed in the shell, and one end of the eccentric wheel component is in transmission connection with the driving unit while the other end of the same is in transmission match with the cutter component to enable the cutter component to move linearly and reciprocatingly. The food processor has the advantages that the cutter component moves linearly and reciprocatingly during cutting, cutting force is large and not easy to get stuck, soft food materials can be cut, smooth cutting is achieved, and better effect in dicing is achieved.

Owner:GUANGDONG BARSETTO ELECTRIC IND CO LTD

Novel high-precision cloth cutting machine for preventing cloth from moving

ActiveCN107500008AAvoid dullingAvoid sticking to each otherArticle deliveryWebs handlingEngineeringControl switch

The invention discloses a novel high-precision cloth cutting machine for preventing cloth from moving. The novel high-precision cloth cutting machine comprises a feeding conveying belt, a front pressurizing roller, a cutting sliding rail, limiting blocking plates, a discharging conveying belt, a rack, a spray device, a cutting cutter blade, insulation balance iron, a control switch and an electromotor. The cutting sliding rail is arranged on the upper surface of a cutting platform and located between the front pressurizing roller and a back pressurizing roller. The limiting blocking plates are located on the two sides of the cutting platform. The insulation balance iron is located on the left side of the rack. The control switch is located at the tail end of the rack. The electromotor is located on the right side of the rack and connected with the cutting cutter blade. According to the novel high-precision cloth cutting machine for preventing the cloth from moving, the cutting sliding rail is arranged, the cutting sliding rail comprises a cutter grinding device and a sliding rail groove, arranging of the cutter grinding device can grind the cutting cutter blade while the cutting cutter cuts the cloth, and the fact that a cutter edge is blunt, and the cloth can not be effectively and fast cut due to the fact that the cutting cutter blade is not ground for a long time is prevented.

Owner:江苏优恩服饰辅料有限公司

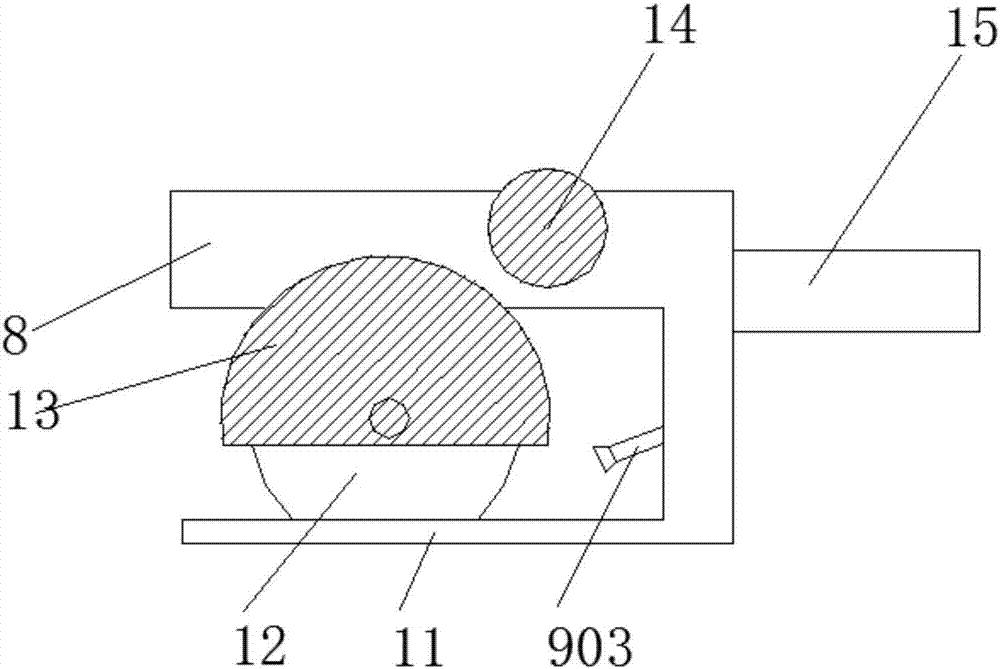

Dustproof type powder grinding machine with unblocking function for coal chemical industry

InactiveCN109731665AImprove dustproof effectAvoid affecting the cutting effectDirt cleaningGrain treatmentsEngineeringCoal chemical industry

The invention relates to a dustproof type powder grinding machine with an unblocking function for coal chemical industry. The dustproof type powder grinding machine comprises a main body, a feeding port, a discharging port and four supports, and further comprises a dustproof mechanism and a unblocking mechanism, wherein the dustproof mechanism comprises two shielding assemblies, each shielding unit comprises a supporting shaft, a supporting rod and a baffle plate, the unblocking mechanism comprises two fixing chambers, reciprocating assemblies and unblocking assemblies are arranged in the fixing chambers, each unblocking assembly comprises a first motor and a moving block. According to the dustproof type powder grinding machine with the unblocking function for the coal chemical industry, through the unblocking mechanism, a feeding pipe can be unblocked, the situation that due to the fact that large-scale coal is clamped in the feeding pipe, the discharging effect is influenced is avoided, through the dustproof mechanism, the feeding pipe can be plugged, so that the situation that due to the fact that dust scatters, the dust is raised, and the surrounding environment is influenced is avoided, and the environmental protection performance of the equipment is improved.

Owner:GUANGZHOU LINDIAN TECH CO LTD

Timber cutting device

InactiveCN110524636APrecise control anglePrecise arc controlCircular sawsBark-zones/chip/dust/waste removalEngineeringMechanical engineering

The invention discloses a timber cutting device. The device comprises a workbench and a cutting assembly, the workbench and the cutting assembly are both arranged above the base. The workbench is installed on the base through a lifting assembly. One end of the lifting assembly is arranged at the bottom of the workbench. One end of the cutting assembly is fixedly installed on the base, the other end of the cutting assembly is fixedly installed on the base, the cutting assembly is arranged on the base through an adjusting device, the adjusting device comprises a rotating assembly and a sliding assembly, the cutting assembly is fixedly installed on the rotating assembly, the lower portion of the rotating assembly is rotationally connected with the sliding assembly, and the sliding assembly isfixedly installed on the base. The rotating assembly and the sliding assembly are adopted, the angle, radian and width of timber cut by the electric saw blade are adjusted, timber cutting with special cutting requirements is met, and the application range is wide; and the lifting assembly is adopted, wood chips at the cutting position can be shaken off in time, the situation that the cutting effect is affected by wood chip accumulation is avoided, meanwhile, the cutting assembly is prevented from being clamped by wood, and working efficiency is improved.

Owner:任宇飞

Cooling device for automobile part cutting

PendingCN106514020AComplete separationImprove cutting effectLaser beam welding apparatusPistonLaser cutting

The invention belongs to the field of machining and particularly discloses a cooling device for automobile part cutting. The cooling device for automobile part cutting comprises a fixing seat. One end of the fixing seat is provided with a clamping mechanism. A laser cutting mechanism is arranged in the middle of the fixing seat and comprises a supporting frame. A first rotating shaft is rotationally connected to the supporting frame. The work end of the first rotating shaft is statically connected with an eccentric wheel. A laser cutter is arranged on the edge of the eccentric wheel. A second rotating shaft is further statically connected with the eccentric wheel. The other end of the fixing seat is connected with a cooling mechanism. The cooling mechanism comprises a cylinder body, a piston, a water inlet, a water outlet, a water outlet pipe, a crankshaft and a connecting rod. The work end of the water outlet pipe is arranged in the first rotating shaft in a penetrating manner and is aligned with part raw materials. The crankshaft is connected with the second rotating shaft. The cooling device for automobile part cutting can cool finished part products obtained after laser cutting and prevent the finished part products from being fused with the part raw materials in the cutting process.

Owner:重庆寅悦恒工贸有限公司

Convenient-to-adjust cutting device

InactiveCN111217517AAdjustable distanceAdjust cutting pressureGlass severing apparatusDrive wheelElectric machine

The invention discloses a convenient-to-adjust cutting device, which comprises a workbench, wherein supporting plates are fixedly connected to the left side and the right side of the top of the workbench, the tops of the two supporting plates are fixedly connected through the bottom of a fixing plate, a driving motor is fixedly connected to the left side of the top of the fixing plate, a driving rotating shaft is fixedly connected to the output shaft of the driving motor, and the bottom end of the driving rotating shaft penetrates through the fixing plate and extends to the exterior of the fixing plate. According to the invention, through the matching of the driving motor, the driving rotating shaft, the driving wheel, the first bearing, the rotating shaft, the driven wheel, the transmission belt, the threaded rotating shaft, the threaded block, the second bearing, the electric push rod, the cutting motor, the cutting rotating shaft and the cutting blade, when glass is cut, the distance between a glass plate and a cutting knife can be adjusted, so that the cutting pressure can be adjusted, the cutting speed is increased, the application range is large, the production cost is reduced, and great convenience is brought to a user.

Owner:侯正建

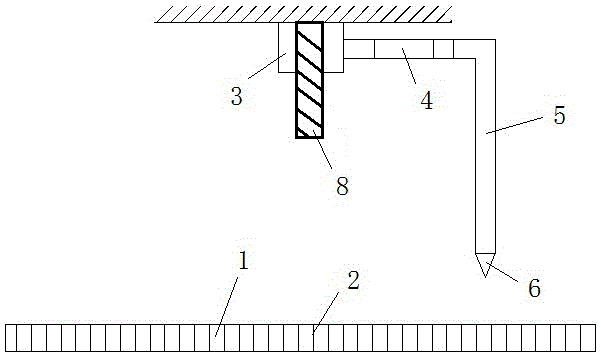

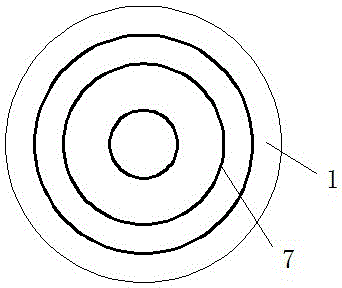

Novel adjustable glass cutting device

The invention discloses a novel adjustable glass cutting device. The novel adjustable glass cutting device is characterized by comprising a workbench used for placement of to-be-cut glass, a fixing column is arranged at a position away from the center of the workbench by a certain height, a rotating shaft is arranged on the outer side of the fixing column, can be adjusted along the fixing column and is provided with an extensible rod along the horizontal direction, a cutting tool used for cutting glass is arranged at the tail end of the extensible rod through a connecting frame, cutting of a circle is completed by the cutting tool when the rotating shaft rotates by a circle, and a heating device is arranged at the bottom of the workbench. Preferably, the heating device is an electric heating device. Preferably, the heating device is composed of a plurality of annular heating wires which are concentric and different in radius. Influence on cutting effect and appearance due to large time difference in the process of cutting is avoided, and convenience is brought to cutting of large-area glass.

Owner:SUZHOU KAIDE MICRO ELECTRONICS CO LTD

Building steel bar cutting device convenient to reduce vibration

The invention discloses a building steel bar cutting device convenient to reduce vibration. The building steel bar cutting device comprises a workbench, the workbench is connected with a protective cover, two sides of the inner top of the protective cover are connected with first electric cylinders, the bottom of the first electric cylinders are connected with clamping blocks, supporting rods located on the same vertical line of the first electric cylinders are arranged on the two sides of the upper end face of the workbench, the upper end of the supporting rods are connected with containing plates, U-shaped grooves are arranged in the containing plates. According to the device, the safety coefficient of the cutting work can be improved through the arrangement of the protective cover, thesupporting rods, the placing plates and the U-shaped grooves are arranged, so that the steel bar can be conveniently placed, the buffering effect can be achieved through the arrangement of the rubbergaskets in the U-shaped grooves, the vibration generated when the steel bar is cut is reduced, through the arrangement of the first electric cylinders and the clamping blocks, the steel bar can be fixed by matching with the U-shaped grooves in the containing plates, so that the phenomenon that the cutting effect is influenced due to vibration is avoided.

Owner:GUILIN JIEYU ENVIRONMENTAL PROTECTION SCI & TECH

Leftover material reprocessing device for computer hardware technology development

InactiveCN112476501AAvoid harmCause some damagesMetal working apparatusTechnology developmentElectric machinery

The invention discloses a leftover material reprocessing device for computer hardware technology development, and relates to the technical field of computer engineering. The leftover material reprocessing device comprises a placing plate, wherein the upper surface of the placing plate is fixedly connected with a supporting plate, the back surface of the supporting plate is fixedly connected with afixing plate, the upper surface of the fixing plate is fixedly connected with a motor, and the output end of the motor extends to the front surface of the supporting plate. The leftover material reprocessing device is reasonable in design structure, through the cooperative arrangement of the motor, a rotating disc, a first connecting rod, a second connecting rod, a limiting rod, a third connecting rod, a fixing block and a cutting knife, a worker does not need to hold a cutting machine to cut, so that the damage to the worker during cutting is avoided, and the potential safety hazard is effectively reduced; and through the cooperative arrangement of a clamping plate, a spring, a moving plate, a moving rod, a clamping plate and a limiting plate, materials can be more conveniently fixed, the materials are prevented from shaking during cutting, and the influence on the cutting effect is avoided.

Owner:阜阳市鑫格特机电设备有限公司

Mechanical product cutting equipment for intelligent manufacturing

ActiveCN113547368AScientific and reasonable structureEasy to useFeeding apparatusMetal working apparatusElectric machineStructural engineering

The invention discloses mechanical product cutting equipment for intelligent manufacturing. The equipment comprises fixing frames; mounting plates are fixedly connected with the top ends of the two fixing frames; a transverse frame is fixedly connected with one side position between the two mounting plates; a conveying platform is fixedly connected with the position, corresponding to the bottom of the transverse frame, between the two fixing frames; a reciprocating translation mechanism is arranged at the top end of the transverse frame; and the reciprocating translation mechanism comprises a lead screw, a movable block, a movable frame, a rotating wheel, an electric push rod, a transverse rod and a rotating motor. The mechanical product cutting equipment for intelligent manufacturing is scientific and reasonable in structure, and safe and convenient to use. The reciprocating translation mechanism is arranged, so that power is transmitted through the cooperation of two transmission wheels and a first belt; through the telescopic characteristic of a tensioning spring, a cushion block is tightly attached to a guide wheel, so that the transverse rod and the guide wheel are driven to rotate; and then through cooperation of a second belt, the rotating wheel and the lead screw are driven to rotate, the movable block and one end of the movable frame are pushed, and a metal plate is cut.

Owner:JIANGSU VOCATION & TECHNICAL COLLEGE OF FINANCE & ECONOMICS

Plastic film production and manufacturing slitting machine and processing process

InactiveCN111824840AWill not be damagedAffect subsequent useArticle deliveryWebs handlingThin membranePlastic film

The invention relates to a plastic film production and manufacturing slitting machine and a processing process. The film production and manufacturing slitting machine comprises a bottom frame, a placing mechanism and a clamping and cutting mechanism. The film production and manufacturing slitting machine and the processing process can solve the following problems existing in the slitting process of plastic films that a, during conventional cutting, a plastic film is typically cut by a common cutting tool, incomplete notches may exist, and the using effect is therefore poor; b, after slitting,because the cut plastic film retracts due to inertia, the effect of clamping the plastic film on two sides of a cutter is poor, the film may be torn, and the process flow is affected; and c, the lengths of plastic film rollers differ due to different width specifications of the plastic films, plastic films of one specification correspond to one supporting rack with regard to traditional equipment,and supporting racks of different specifications need to be switched when the plastic films of different specifications need to be placed, and the process flow is complicated.

Owner:尤晨曦

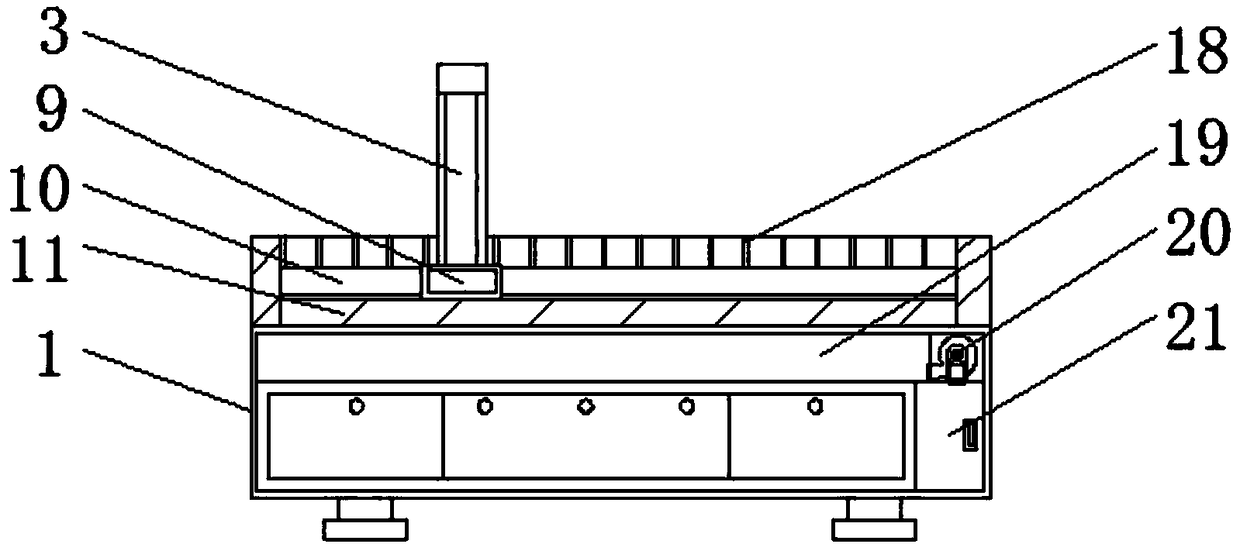

Physical sample cold-state processing equipment

ActiveCN110385648AAvoid cloggingAvoid affecting the cutting effectAbrasive machine appurtenancesAbrasive blasting machinesEngineeringWater cut

The invention discloses physical sample cold-state processing equipment which comprises a case, a guide rail is mounted on the two side walls of the case; a portal frame is in sliding fit with the guide rail in a clamping manner; a water cutting head is mounted on the portal frame; a plurality of placing plates are fixedly mounted between the tops of the inner walls of the two sides of the case; aworkpiece is placed on the placing plate below the water cutting head; flow-guiding clamping plates are mounted on the placing plates on the two sides of the workpiece and tightly press the two sidesof the workpiece; and a dynamic filtering mechanism is mounted between the inner walls of the case below the placing plates. The workpiece is placed on each of the placing plates, clamped and fixed by the flow-guiding clamping plates; the water cutting head cuts the workpiece; the dynamic filtering mechanism pushes the water body in the case to fluctuate the water surface; the water surface fluctuation pushes through the surface of the workpiece along the flow-guiding clamping plates, so that carborundum and cuttings are pushed in the water body in the case; the dynamic filtering mechanism dynamically filters the water body in the case; and during the filtering process, the water bodies at the upper part and the bottoms of the case are divided, and the water body at the drainage part is kept clean, so that drainage and cyclic utilization are facilitated.

Owner:JIANGSU DAIMIPU PRECISION EQUIP CO LTD

Anti-obstruction type concentrator with automatic feeding function for ore dressing

InactiveCN110124370AImprove practicalityReduce workloadSettling tanks feed/dischargeEngineeringSettling basin

The invention relates to an anti-obstruction type concentrator with an automatic feeding function for ore dressing. The concentrator comprises a body, a settling basin, and two support rods and also comprises a feeding mechanism and two vibration mechanisms. The feeding mechanism comprises a feeding box, a moving plate, a moving rod, a push plate, and two driving assemblies. Each vibration mechanism comprises a support plate, a slide block, an adjusting rod, an adjusting assembly, a support shaft, a swing plate, a vibration block, and a contact block. Through the vibration mechanisms, the settling basin is vibrated intermittently, the obstruction of the settling basin is avoided, the discharge effect is guaranteed, through the feeding mechanism, automatic feeding is realized, and the workload for an operator is relieved.

Owner:SHENZHEN ANSIKE ELECTRONICS TECH CO LTD

Novel thermoplastic polyurethane elastomer cutting machine capable of sucking dust

InactiveCN105500418AAvoid offsetImprove cutting efficiencyMetal working apparatusThermoplastic polyurethaneEngineering

The invention discloses a novel thermoplastic polyurethane elastomer cutting machine capable of sucking dust. The machine comprises a shell and a blade, and is characterized in that a guide base is arranged in the shell; a chute is formed in the guide base; a slide plate is arranged on the guide base; a guide rail matched with the chute is arranged at the lower end of the slide plate; a driving device is arranged at the upper end of the slide plate, and is connected with the blade; a cutting motor is arranged in the shell; a bevel gear is arranged at an output end of the cutting motor; a thread matched with a ball nut is arranged on an output shaft of a pressing motor; the shell is provided with a controller; the controller is respectively connected with a sensor and the pressing motor; multiple fans are arranged on the inner wall of the shell, and are provided with pipes; the pipes extend into a collecting barrel; and support legs are arranged between the fixed plate and the shell. The novel thermoplastic polyurethane elastomer cutting machine capable of sucking dust can improve the working efficiency.

Owner:CHENGDU DUOLIDUO NEW MATERIAL

Printing paper cutting device capable of ensuring quantitative cutting and smoothing printing paper

InactiveCN111687897ASame sizeGuaranteed uniformityMetal working apparatusReciprocating motionIndustrial engineering

The invention relates to the technical field of printing, and discloses a printing paper cutting device capable of ensuring quantitative cutting and smoothing printing paper. The printing paper cutting device capable of ensuring the quantitative cutting and smoothing the printing paper comprises a base, the base is used for supporting and stabilizing the whole device, and a second gear, a third gear, a first connecting rod and a moving block match for use, so that a moving block is used for driving a cutting knife to do reciprocating motion to quantitatively cut the paper, it is guaranteed that the size of the cut paper is consistent, the uniformity of products is guaranteed, through cooperative use of a first gear, a first sliding sleeve, a second connecting rod and a smoothing block, thepaper can be smoothened when the printing paper is cut, the flatness of the paper is guaranteed, the situation that creases exist in a cutting process and influence the cutting effect is prevented, through cooperative use of a second sliding sleeve, a first supporting rod, a second supporting rod and a clamping plate, it is guaranteed that the folded paper is kept stable through the clamping plate when the paper is cut, and therefore shaking generated in the paper cutting process is avoided, and the cutting face is more neat.

Owner:熊浩浩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com