Plastic film production and manufacturing slitting machine and processing process

A technology of plastic film and slitting machine, which is applied in the direction of thin material processing, winding strips, sending objects, etc., and can solve the problems of complex process, poor use effect, frequent differences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

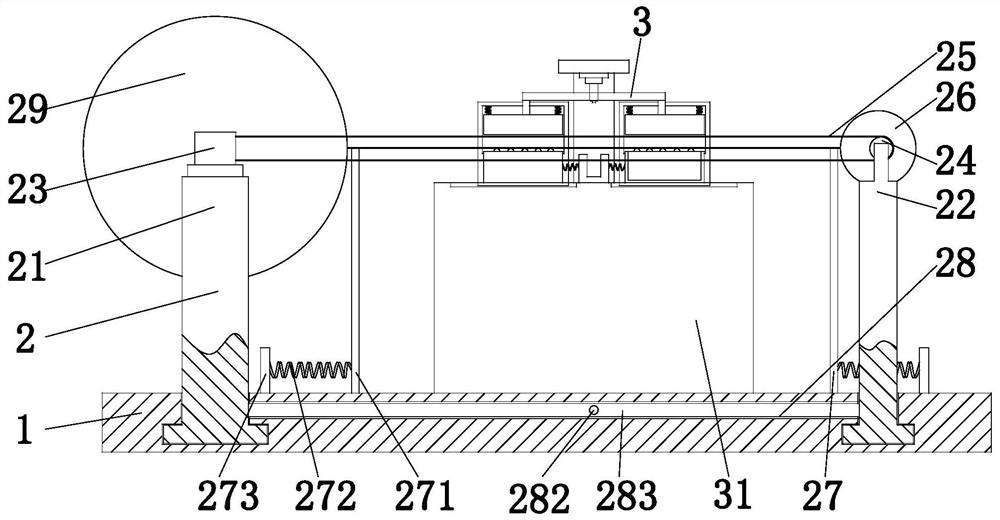

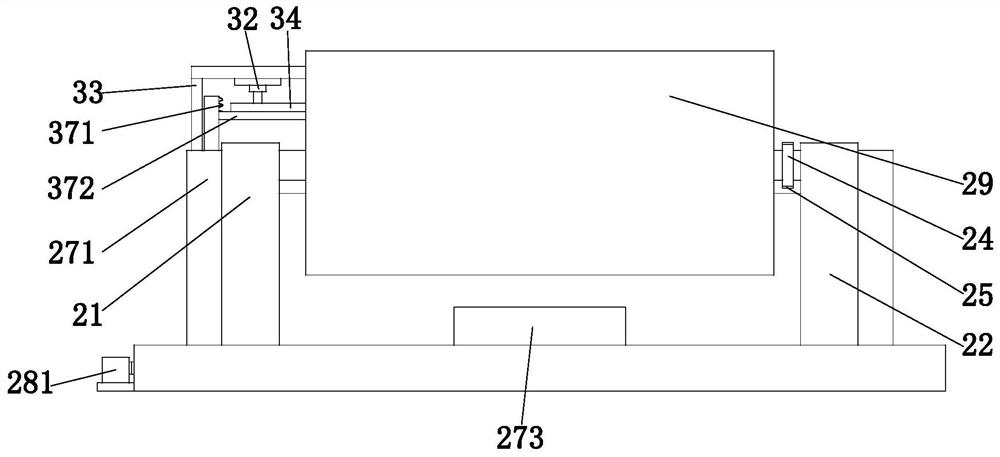

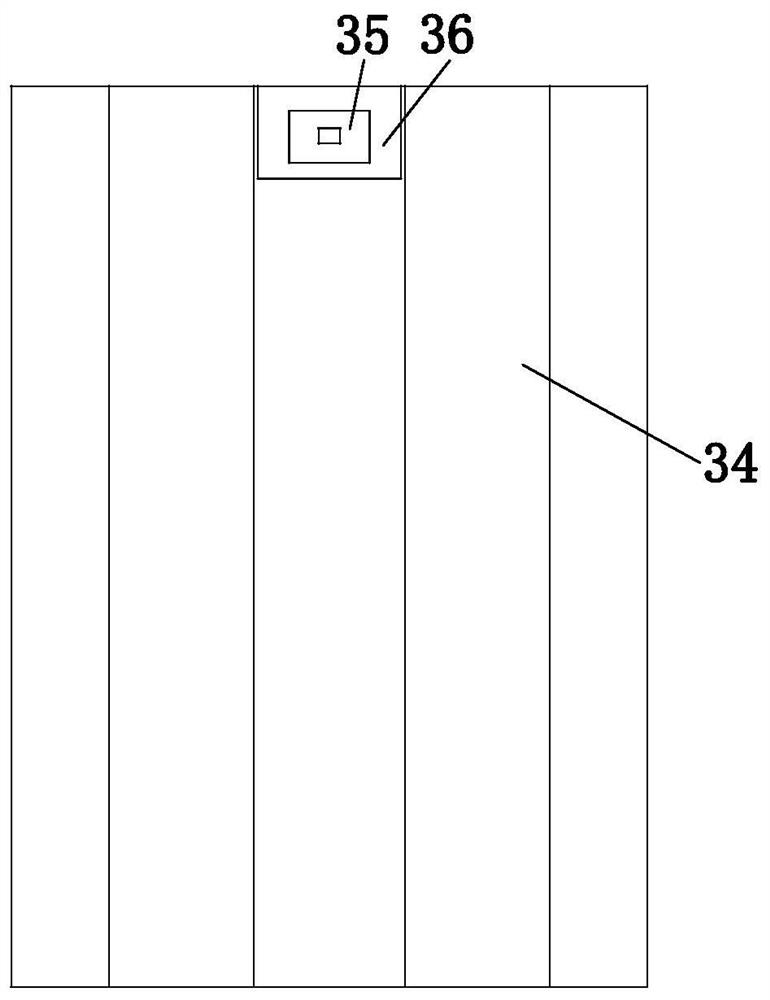

[0029] Such as Figure 1 to Figure 6 As shown, a plastic film production and cutting machine includes a bottom frame 1, a placement mechanism 2, and a clamping and cutting mechanism 3. The bottom frame 1 is installed on the ground, and the placement mechanism 2 is slidably installed on the bottom frame 1, the clamping and cutting mechanism 3 is arranged in the middle of the placement mechanism 2, and the clamping and cutting mechanism 3 is installed on the bottom frame 1.

[0030] The placement mechanism 2 includes a No. 1 support frame 21, a No. 2 support frame 22, a rotating motor 23, a gear 24, a chain 25, a winding roller 29, a collection roller 26, a limit branch chain 27 and a distance adjustment branch chain 28, Wherein said bottom frame 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com