Timber cutting device

A cutting device and wood technology, applied in the direction of sawing equipment, wood processing equipment, circular saws, etc., can solve the problems of manual pressing, affecting cutting effect and work efficiency, easy to get stuck in wood, etc., to improve work efficiency and enhance cutting Effect, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

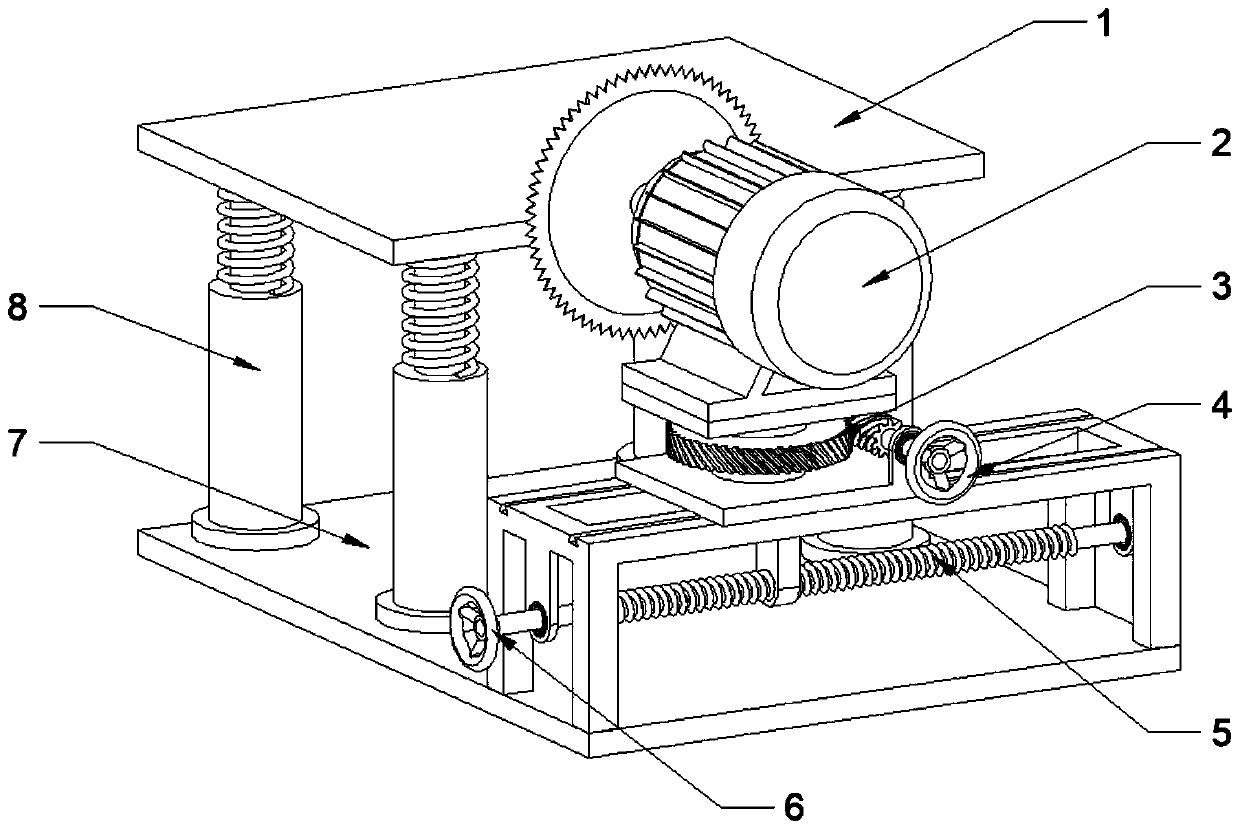

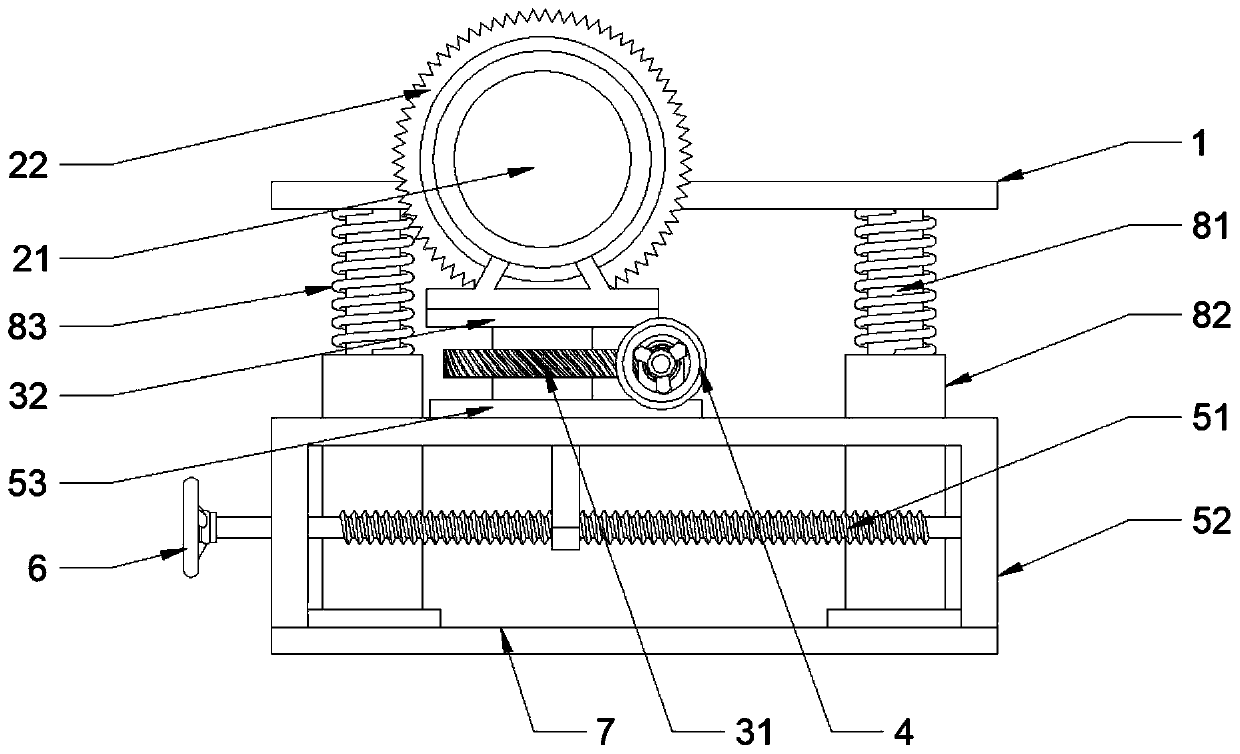

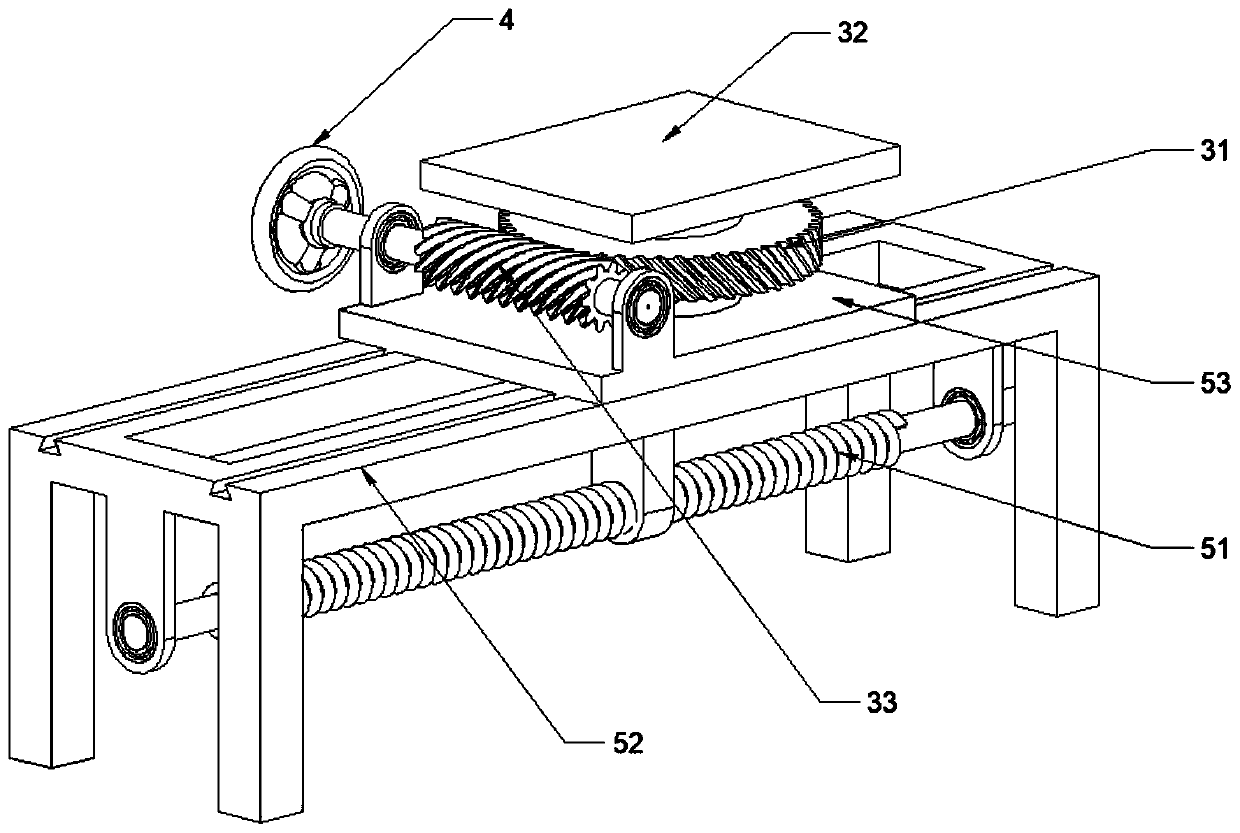

[0023] see Figure 1~3 , in an embodiment of the present invention, a wood cutting device includes a workbench 1 and a cutting assembly 2, the workbench 1 and the cutting assembly 2 are both arranged above the base 7, and the workbench 1 is installed on the base through a lifting assembly 8 On the base 7, one end of the lifting assembly 8 is arranged on the bottom of the workbench 1, and the other end is fixedly installed on the base 7, and the cutting assembly 2 is arranged on the base 7 through an adjusting device, and the adjusting device includes a rotating assembly 3 and a sliding assembly 5, the cutting assembly 2 is fixedly installed on the rotating assembly 3, the bottom of the rotating assembly 3 is connected to the sliding assembly 5 in rotation, and the sliding assembly 5 is fixedly installed on the base 7; the workbench 1 It is used to place and fix the wood, which is convenient for the cutting assembly 2 to cut. The rotating assembly 3 can drive the cutting assemb...

Embodiment 2

[0029] see Figure 4 , in the embodiment of the present invention, a wood cutting device, on the basis of embodiment 1, the rotating handle 4 and the sliding handle 6 are respectively replaced by a rotating motor 9 and a sliding motor 10, and the rotating motor 9 is fixedly installed on the sliding bottom plate 53, and set in linkage with the worm 33 through a coupling, the rotating motor 9 drives the worm 33 to rotate, and can adjust the cutting angle of the cutting assembly 2; the sliding motor 10 is fixedly installed on the base 7, and through the coupling The device is set in linkage with the adjusting screw 51, the sliding motor 10 drives the adjusting screw 51 to rotate, and the cutting width of the cutting assembly 2 can be adjusted; the angle, radian and width of wood cutting are precisely controlled by the rotating motor 9 and the sliding motor 10, and the cutting effect is enhanced , Change manual mode to automatic mode, reduce labor intensity and improve work effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com