Mechanical product cutting equipment for intelligent manufacturing

A technology of mechanical products and cutting equipment, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of unreasonable use of power, affecting the cutting effect of metal plates, reducing the efficiency of production, etc., to achieve safe use The effect of convenience, improving fixation and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

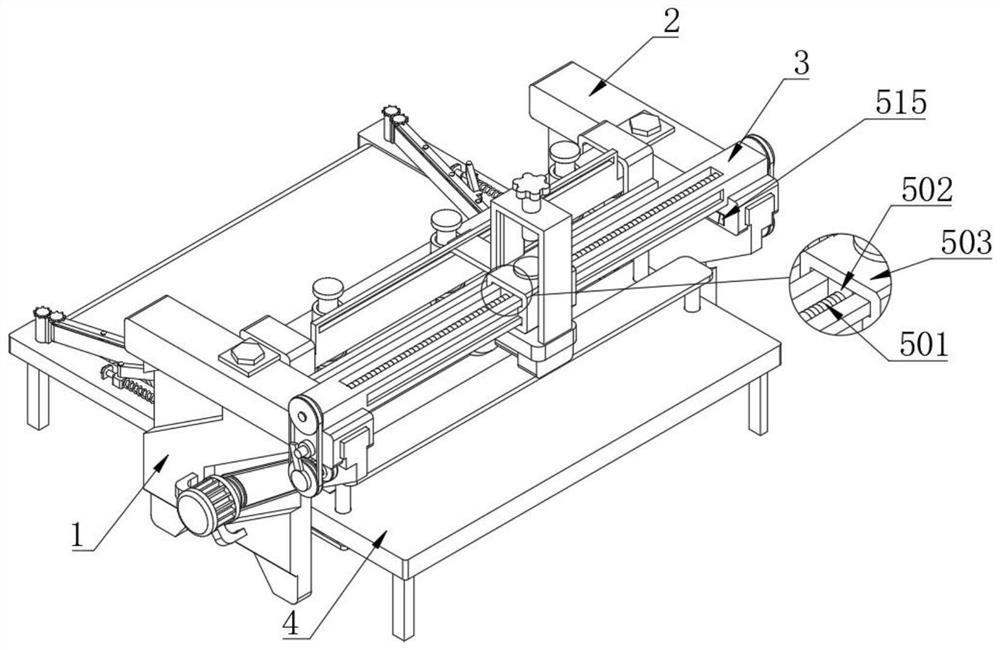

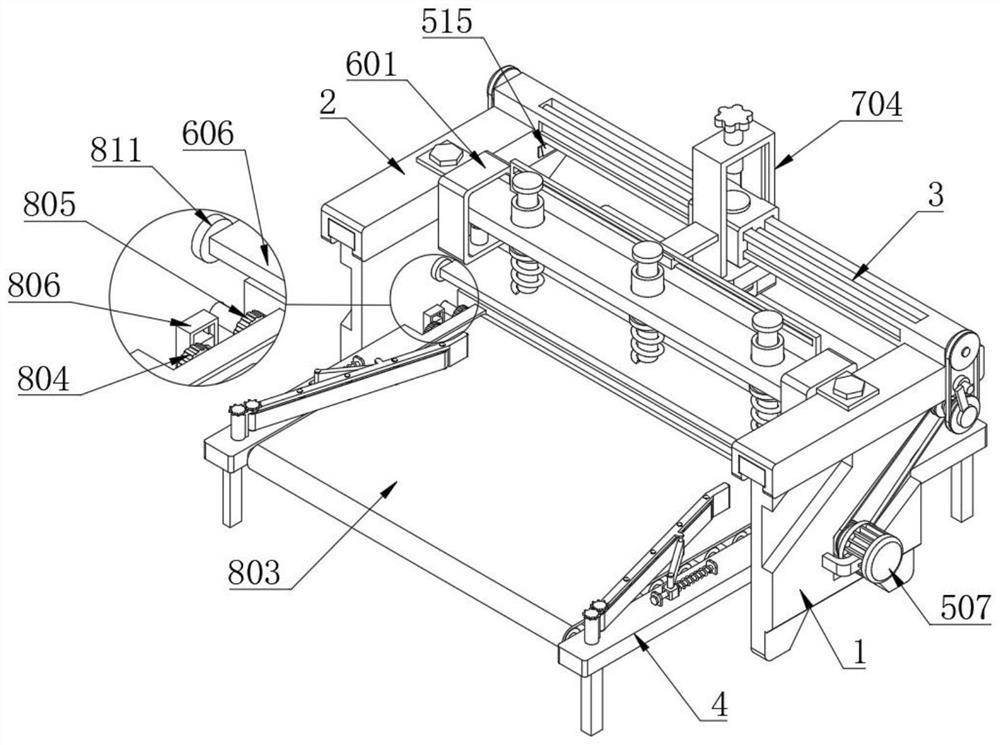

[0061] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a mechanical product cutting equipment for intelligent manufacturing, including a fixed frame 1, the tops of the two fixed frames 1 are fixedly connected with the mounting plate 2, and the position on one side between the two mounting plates 2 The horizontal frame 3 is fixedly connected at each position, and the conveying platform 4 is fixedly connected with the bottom position of the horizontal frame 3 between the two fixed frames 1;

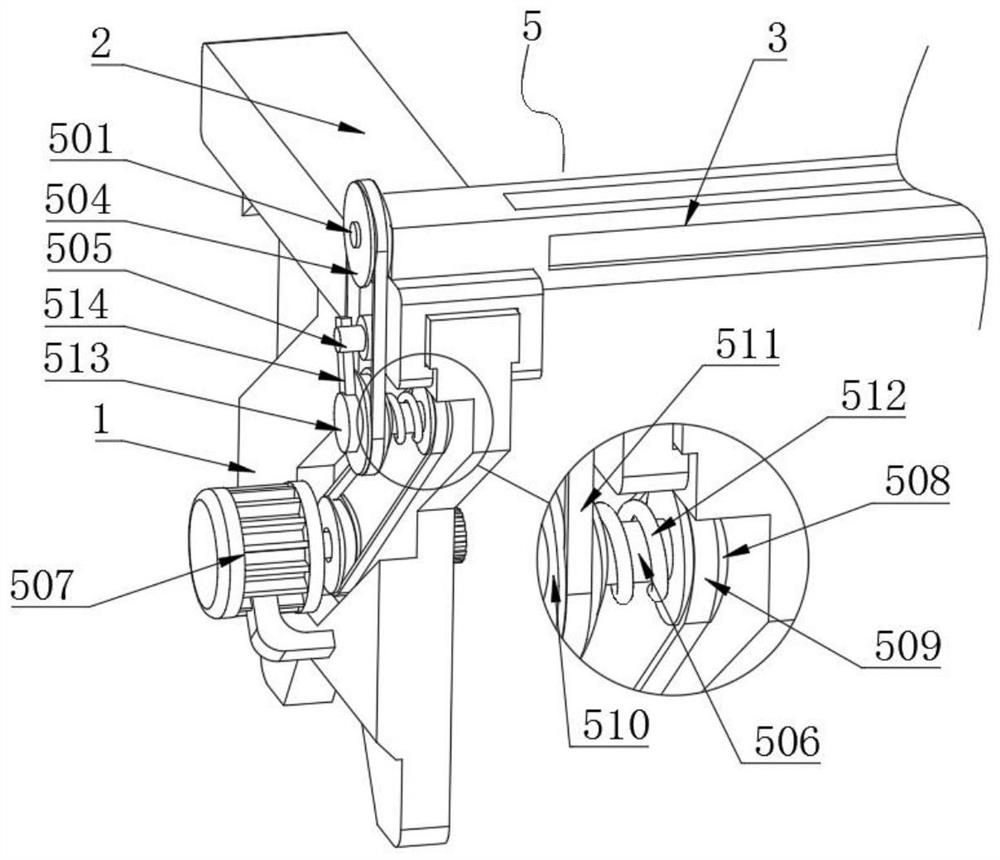

[0062] The top of the horizontal frame 3 is provided with a reciprocating translation mechanism 5, and the reciprocating translation mechanism 5 includes a screw mandrel 501, a movable block 502, a movable frame 503, a runner 504, an electric push rod 505, a cross bar 506, a rotating motor 507, a transmission wheel 508, a second One belt 509, guide pulley 510, second belt 511, tension spring 512, protruding rod 513, turning block 514 and touch swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com