A split pin bending pliers

A technology of cotter pins and bending pliers, which is applied in the field of cotter pin assembly, can solve the problems of difficult assembly of cotter pins, process standard requirements and low assembly efficiency, and achieve the effects of light tools, convenient and quick bending, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

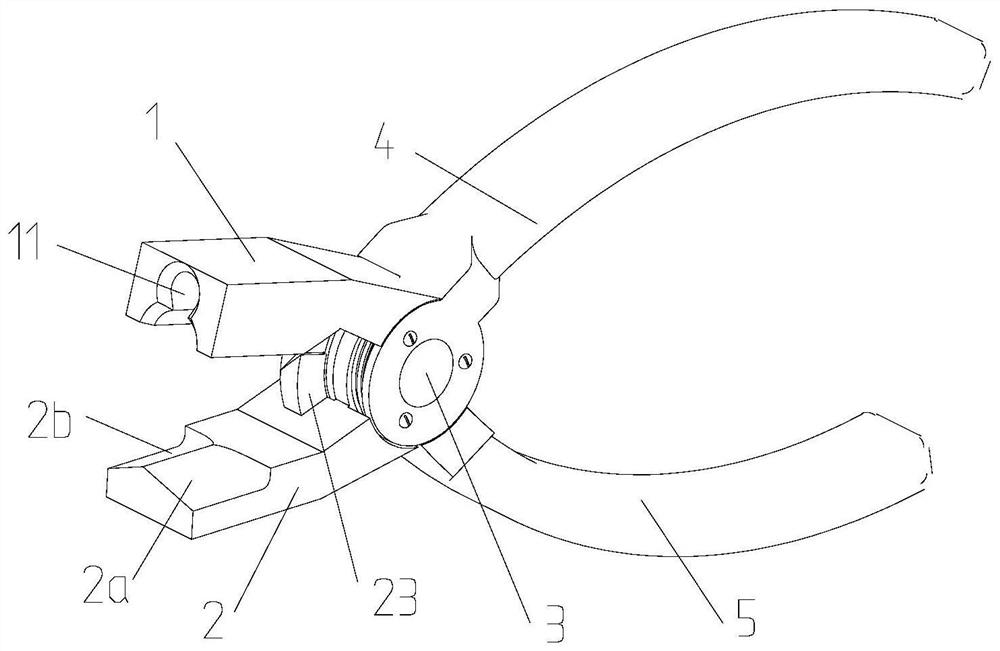

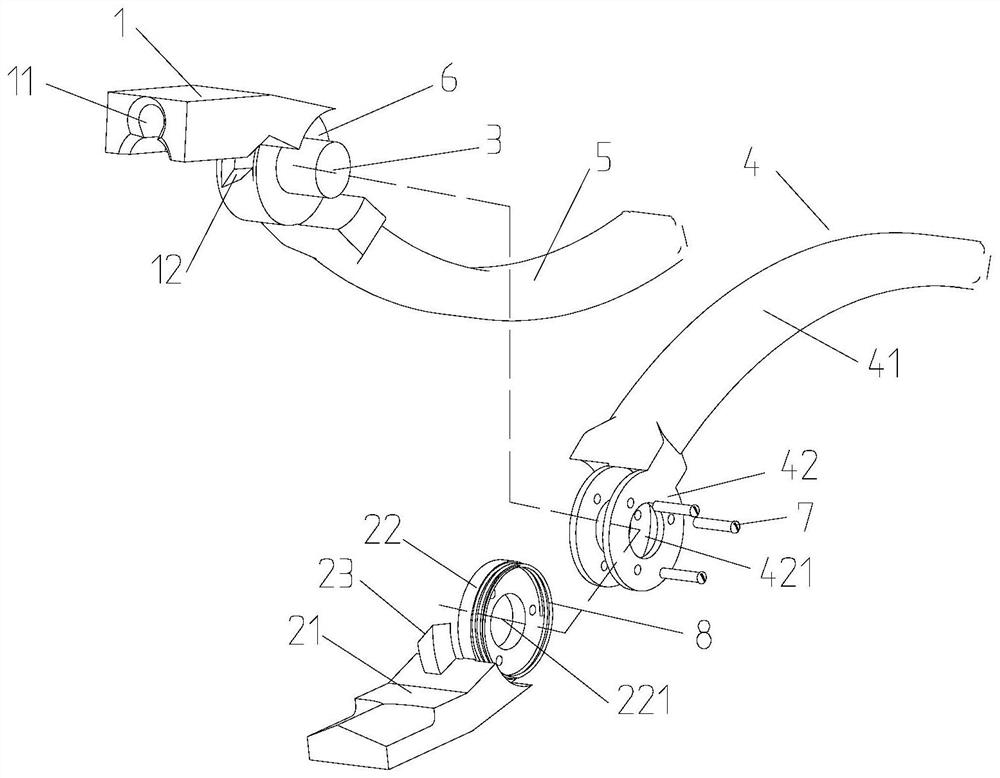

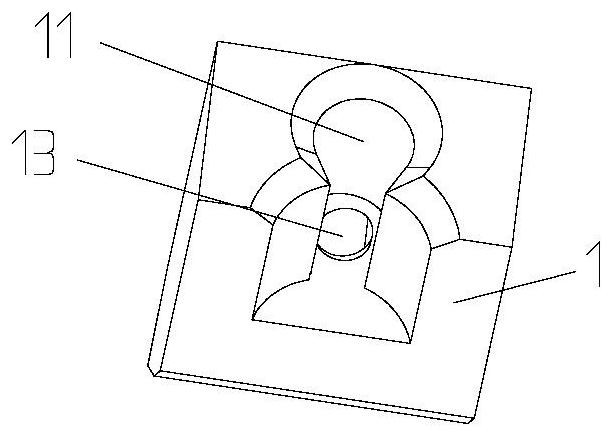

[0031] like Figure 1-7 It is a specific embodiment of the split pin bending pliers of the present invention, which includes: an upper pliers body 1 and a lower pliers body 2 hinged by a first rotating shaft 3 , and the upper pliers body 1 is at the end away from the first rotating shaft 3 . There is a positioning groove 11 for accommodating the arc end A1 of the split pin A; the lower jaw body 2 is provided with an intersecting first action surface 2a and a second action surface 2b on the upper surface of the end portion away from the hinge shaft , the first action surface 2a and the second action surface 2b are respectively used to cooperate with the first leg A2 and the second leg A3 of the cotter pin A; also include a device for driving the lower clamp body 2 to be opposite to the upper The trigger part for sliding of the forceps body 1 includes a first bump 12 arranged on the lower side of the upper forceps body 1 and a second bump 23 arranged on the upper side of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com