Small space docking mechanism based on molded surface guiding three-jaw locking action time sequence

A technology of space docking and movement, which is applied to the docking devices of aerospace vehicles, motor vehicles, and space navigation equipment, etc., and can solve problems such as limited launch capabilities, low precision, and damage to electrical connector pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and advantages to solve the present invention more clearly, and will be described in detail below with reference to the accompanying drawings and specific examples.

[0022] The present invention provides a small spatial docking mechanism based on the timing of the type surface-directed trip.

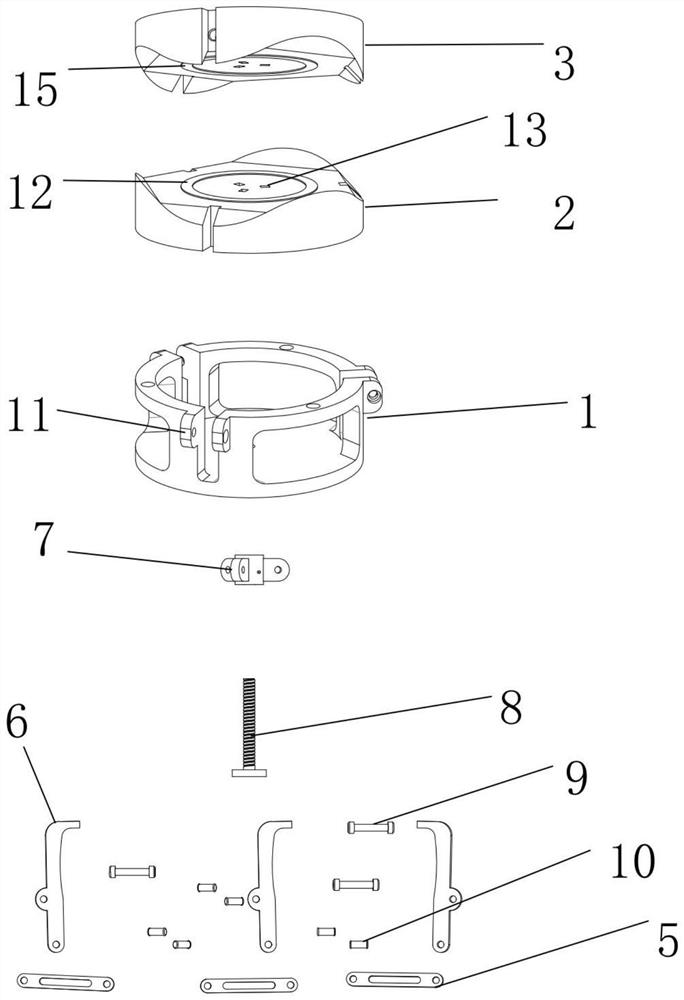

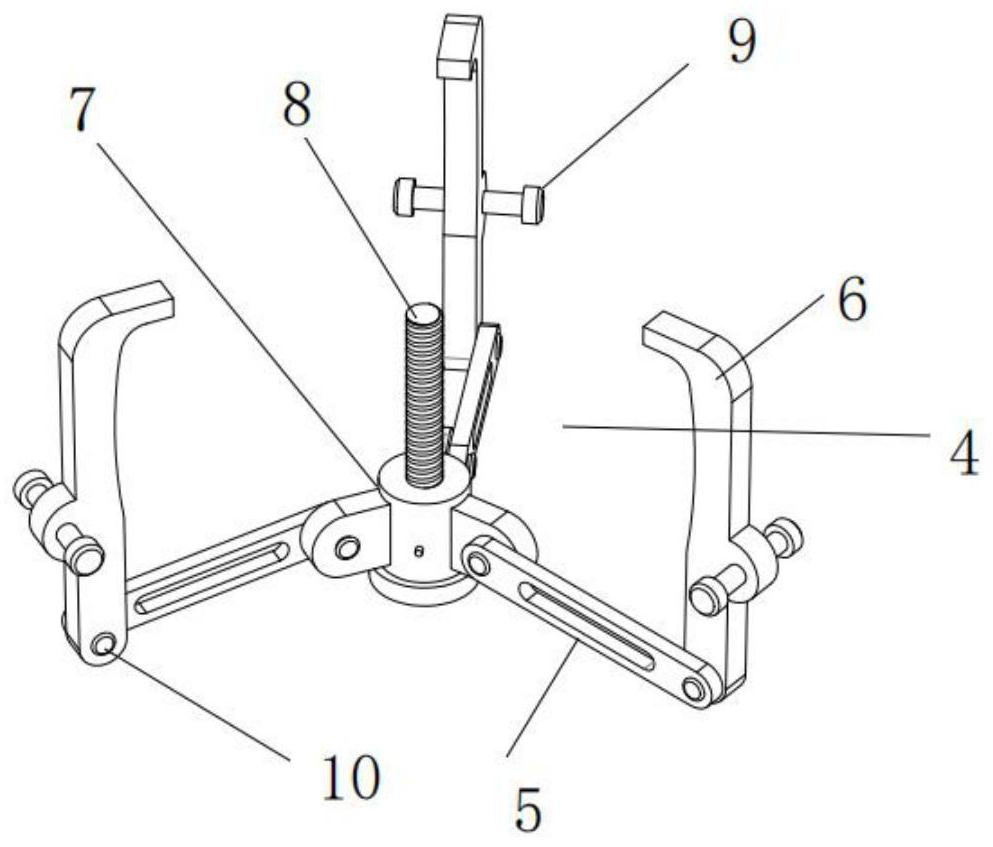

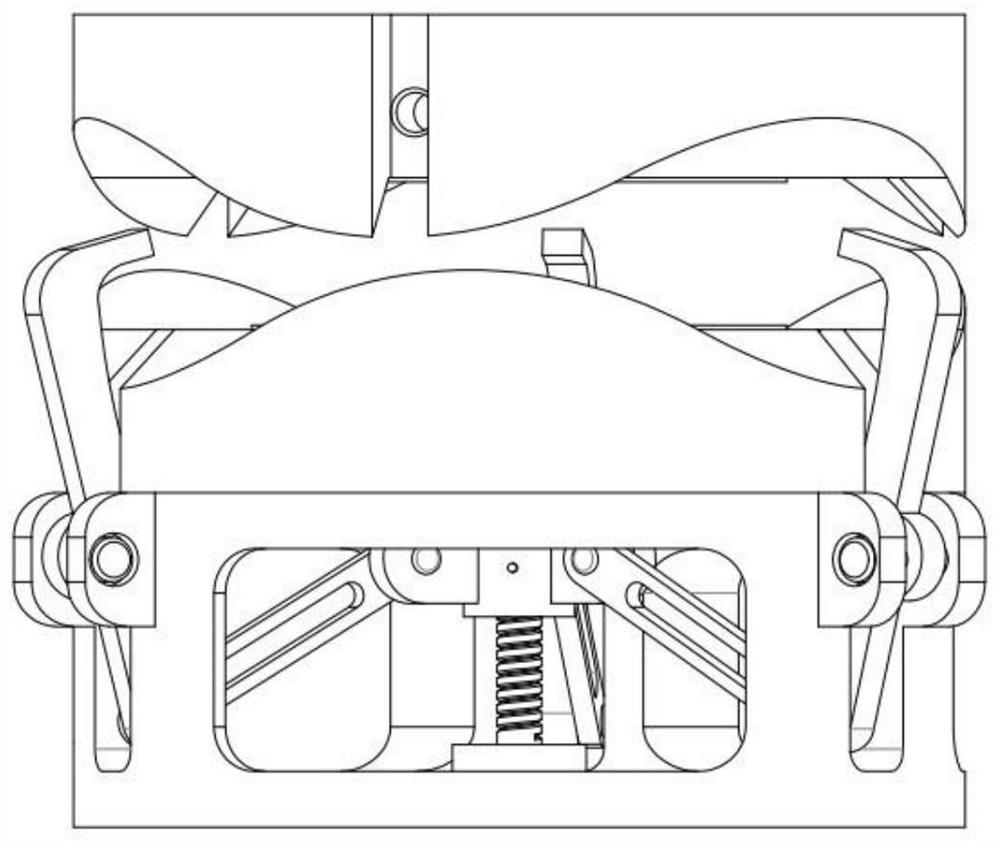

[0023] like figure 1 , figure 2 As shown, the apparatus includes a fixed stage 1, a service drive end 3, a target passive end 2, and a transmission system 4, a transmission system 4 includes a link 5, a lock arm 6, a three ear nut 7, a lead screw 8, a long pin 9 and Short sales 10, the fixing table 1 and the target passive end 2 are fixedly connected by the bolt, the target passive end 2 and the service active end 3 docking, the target passive end 2 and the service active end 3 pair the outer profile of the sinusoidal curve, the transmission system 4 Mounted in the fixed stage 1, the fixed stage is distributed in a fixed ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com