Special device for replacing belt by driving novel belt by old belt

A special device and belt technology, which is applied in the field of replacement and maintenance of large belt conveyor belts, can solve the problems of difficult storage of old belts, small maintenance space, and labor-intensive effort, and achieve the effects of shortening the construction period, reducing labor intensity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

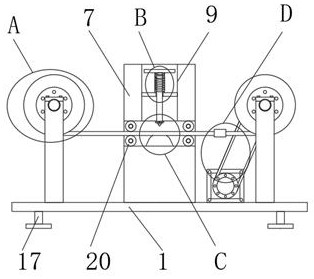

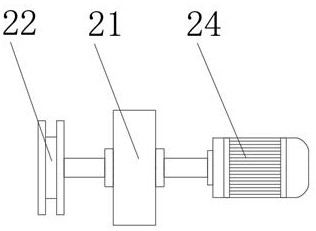

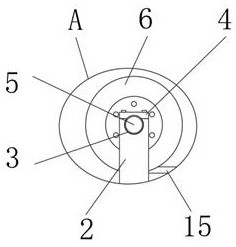

[0033] The difference between this embodiment and Embodiment 1 is that: the four corners of the bottom wall of the base 1 are fixedly connected with a support 17, and the bottom of the support 17 is provided with a non-slip foot pad, which plays the role of non-slip placement of the device body. 8 The openings on both sides are vertically symmetrically provided with guide rollers 20. The guide rollers 20 are slidably connected with the old belt 15 to guide the old belt 15. The output end of the driving motor 24 is connected to the input end of the reducer 21, which is beneficial to reducer speed. 21 deceleration output power, a spring 25 is fixedly connected between the top wall of the mounting plate 10 and the bottom wall of the grip bar 13, the slide bar 12 is located in the spring 25, the grip bar 13, the cutter 14 and the slide bar 12 are designed as elastic mechanisms, which is convenient for use Rear elastic return.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com