Film coating method and clamp for conductive non-metal oxide material

A non-metallic oxide, fixture technology, applied in metal material coating process, nanotechnology for material and surface science, sputtering coating, etc., can solve the problems of radar fogging and frost, affecting detection effect, etc. The effect of restoring normal functioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

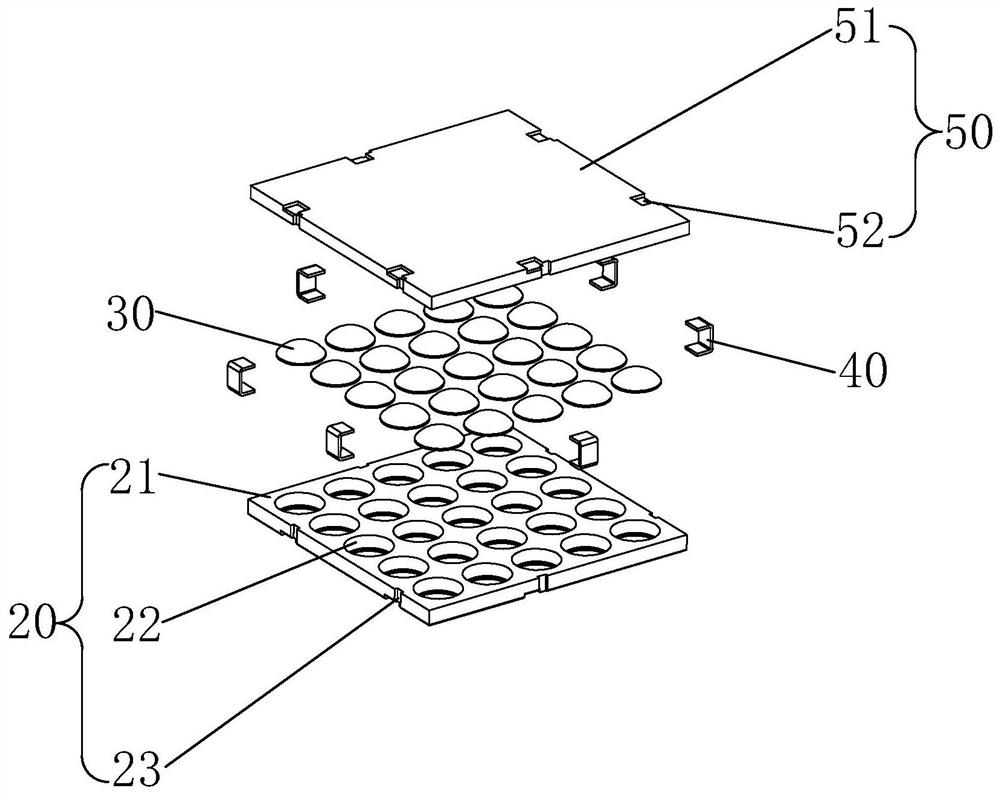

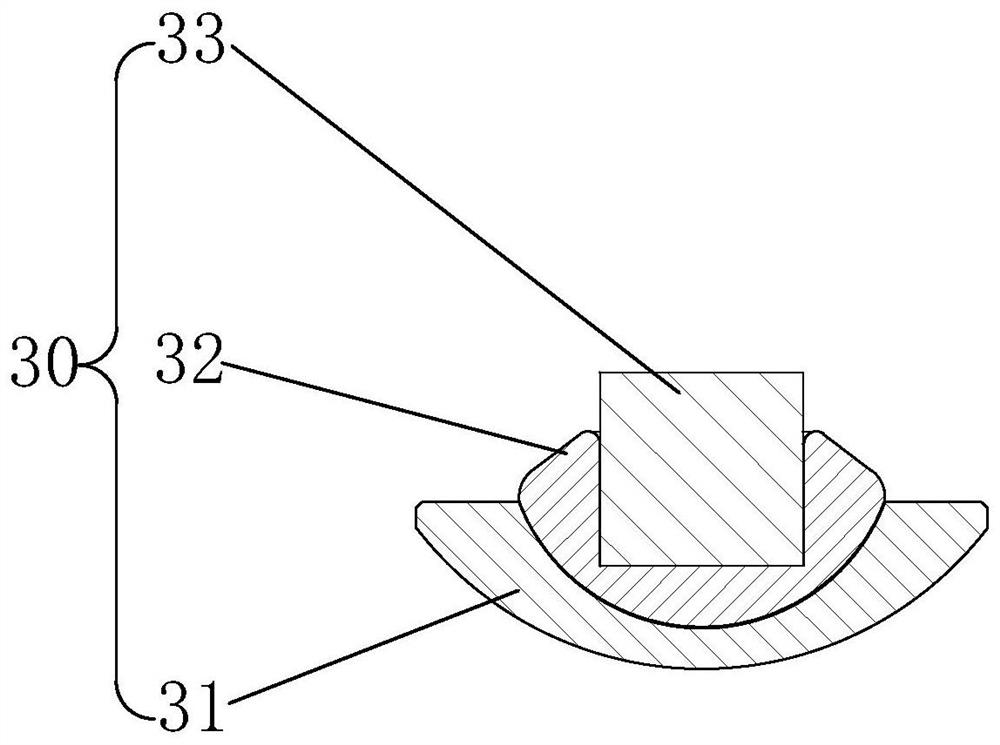

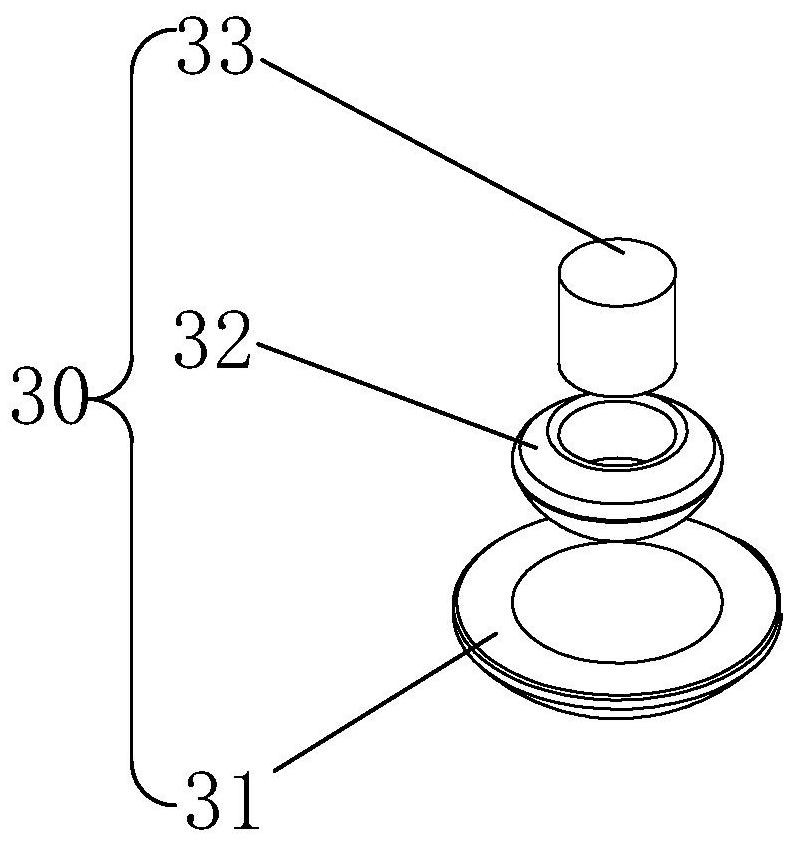

[0015] see figure 1 , figure 2 , image 3 and Figure 4 , showing an embodiment of the present invention, a coating method and fixture for conductive non-metal oxide materials, the coating piece forms a dense and firm nano-film layer on its surface through vacuum coating, and the film layer cannot affect The normal functional effect of the concave-convex surface can reach a certain standard resistance range, so that it can achieve rapid heating function through the inductive effect, so that the radar surface can be quickly defrosted and the normal function can be restored. The fixture includes a base 20, a magnetic cap 30, a card Buckle 40 and upper template 50, the base 20 includes a base body 21, a mold groove 22 and a buckle groove 23, the mold groove 22 is evenly distributed in the base body 21, and the buckle groove 23 is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com