Concrete conveying and pouring equipment

A technology of concrete and equipment, which is applied in the field of concrete pouring, and can solve problems such as the difficulty of parking concrete pump trucks, the labor cost of chute blocking materials, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

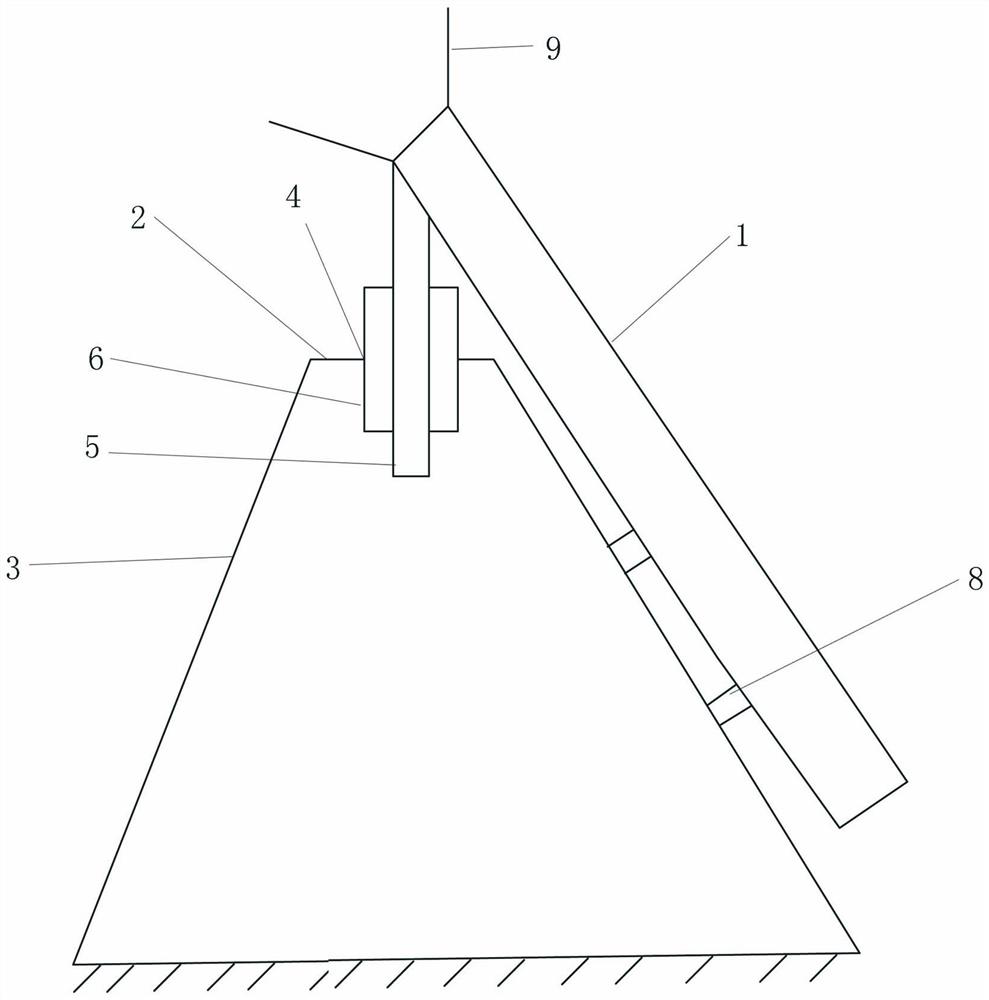

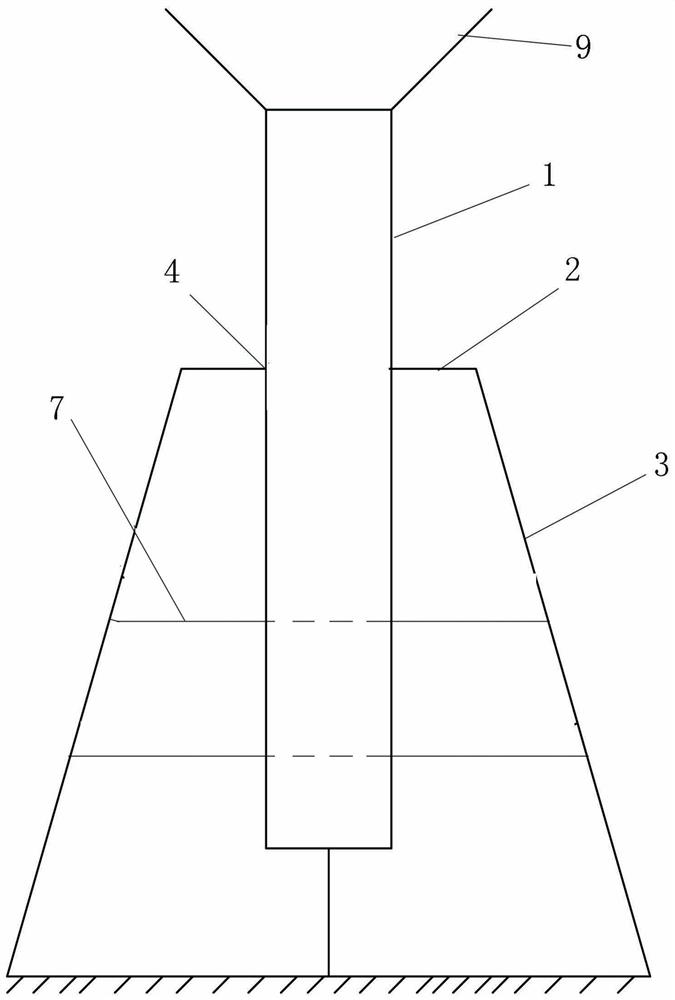

[0017] This embodiment takes Yiyi Expressway K78+199 Shengjigeng Bridge Left Section 5#, 6#, 7# as an example to describe in detail.

[0018] 1. Project overview

[0019] Newly build Yibin-Yiliang Expressway SG6 Subdivision II, line mileage pile number K77+034~K83+369, total length 6.235km, two-way four-lane, separated roadbed width 12.25m, design speed 80km / h.

[0020] Concrete pouring works for caps 5#, 6#, 7# on the left side of Shengjigeng Bridge, and 5#, 6#, 7# caps on the right side. The cumulative concrete volume is 1317 square meters. These caps have a special geographical location, located in a valley surrounded by high slopes and steep cliffs on three sides. The site is narrow and the terrain is steep, making transportation extremely inconvenient.

[0021] The existing sidewalk is 16 meters away from the nearest right 7# cap in a straight line, and the height difference is more than 30 meters. The concrete pump truck can only be supported on the sidewalk, which will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com