Liquid coating device and method

A coating device and coating technology, which is applied in the direction of architecture and building construction, etc., can solve the problems of increasing the penetration rate of liquid coating tools, etc., and achieve the effect of uniform and continuous material supply, uniform quality, and improved coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Embodiment 1 of a liquid coating method using the above-mentioned liquid coating device comprises the following steps,

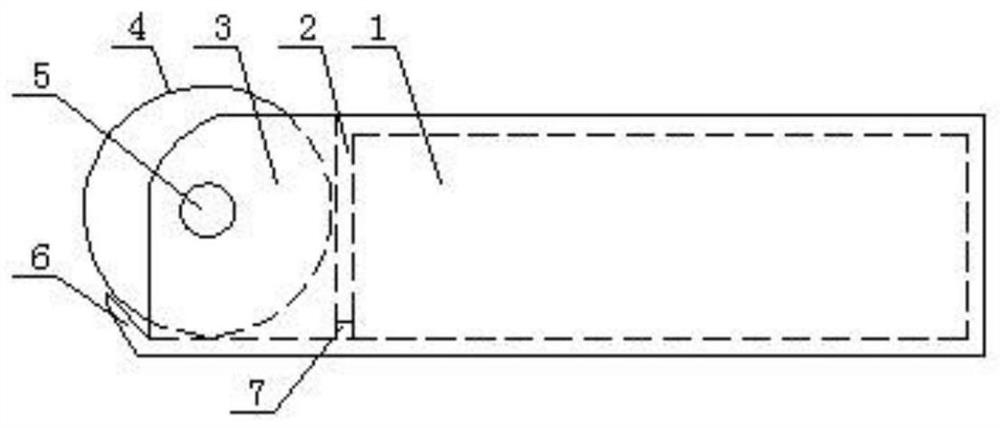

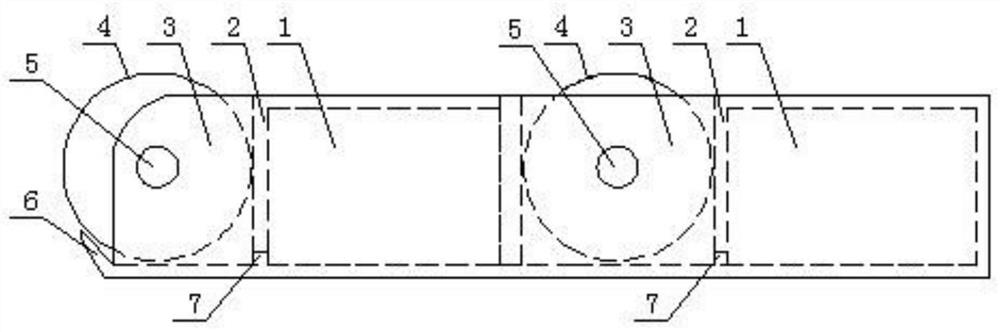

[0091] Step 1, use figure 1 The device in the above is used to coat the liquid on the horizontal top surface. The operator mounts on the support, and within the range of the support, holds the horizontal liquid storage tank 1 with his hand to ensure the horizontal state. The operator moves his body and adjusts it by hand. The degree of fit and compaction between the horizontal coating roller 4 and the horizontal top surface allows the upper half of the horizontal coating roller 4 at one end to roll and paint sequentially row by row on the horizontal top surface.

[0092] Step 2, when adding liquid, tilt the coating roller to the highest point, inject liquid from between the horizontal coating roller 4 and the common side wall 2, and make it flow into the horizontal liquid storage bin 1 through the air inlet 7.

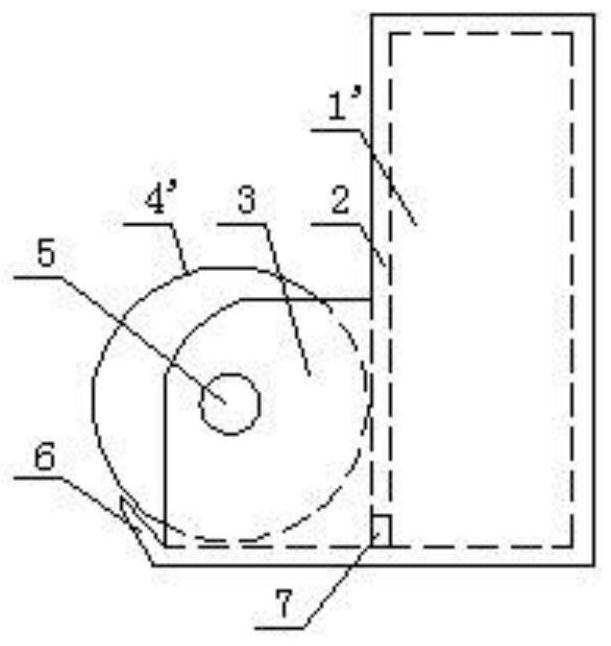

[0093] Step 3, use figure 2 In the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com