Self-lubricating sliding support for aluminum alloy doors and windows and using method of self-lubricating sliding support

A self-lubricating technology for aluminum alloy doors and windows, which is applied to door/window accessories, engine lubrication, hinge plates, etc., can solve the problems of doors and windows that cannot be opened smoothly, the opening and closing of doors and windows is awkward, and the sliding performance is reduced, so as to increase lubrication degree, reduce friction, reduce the effect of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

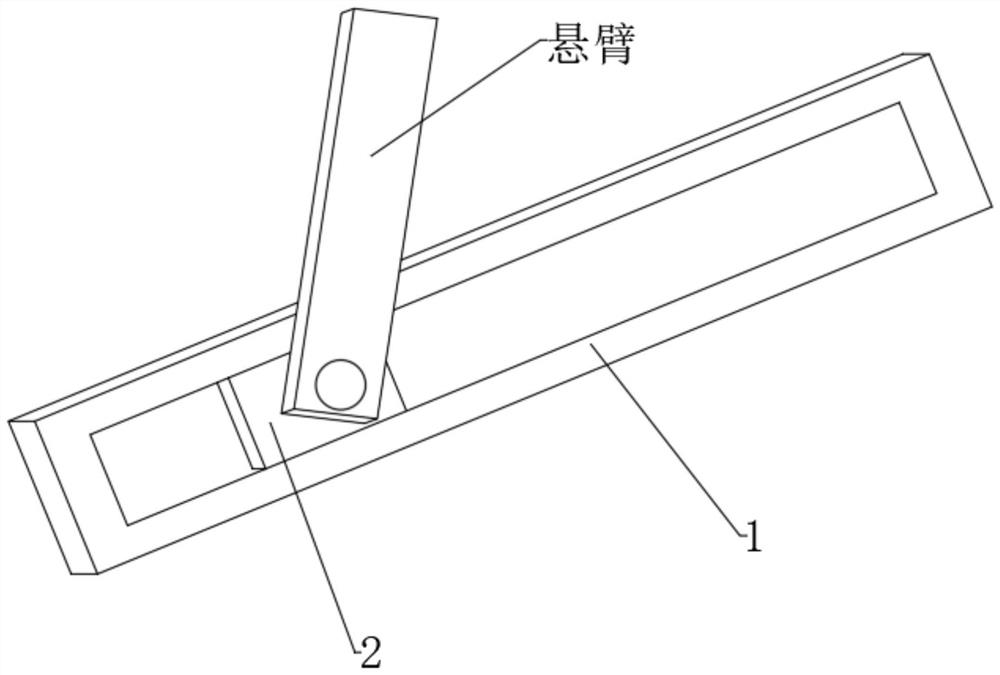

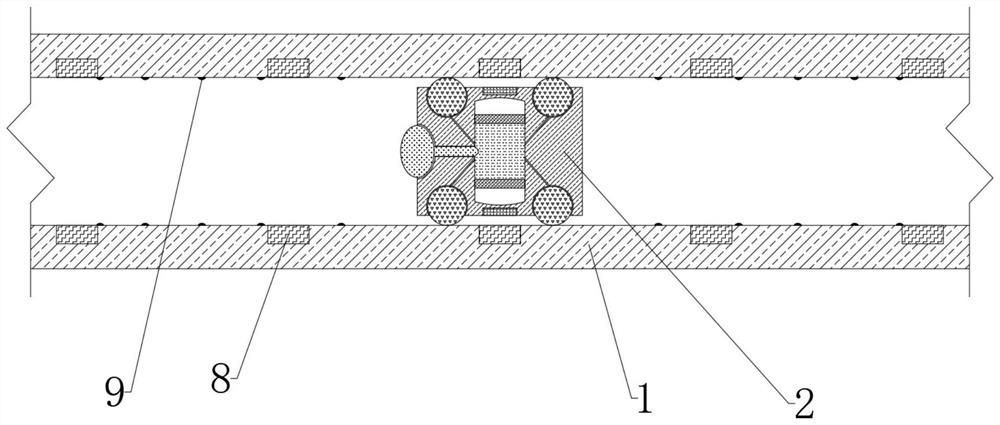

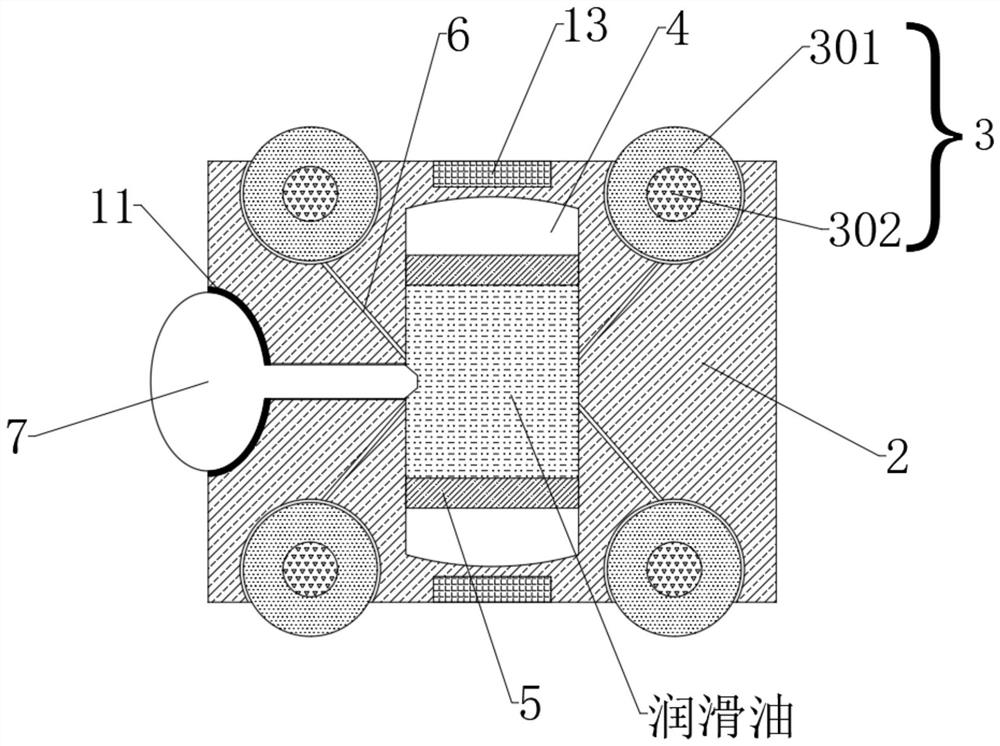

[0047] see Figure 1-8 , a self-lubricating sliding brace for aluminum alloy doors and windows, including a slide rail body 1, see figure 1 The slide rail body 1 is slidably connected with a slider body 2, and the slider body 2 is rotatably connected with a cantilever. Both side walls of the slider body 2 are provided with inlay grooves, and balls 3 are movably inlaid in the inlay grooves. Please refer to 3, the ball 3 includes a hollow sphere 301 and a magnetic ball 302, the magnetism of the magnetic ball 302 is the same as that of the magnetic resistance block 8, when the ball 3 is close to the magnetic resistance block 8, the magnetic resistance block 8 has a repelling force to the ball 3, Like this, when the wind blows the doors and windows, the amplitude of its swaying can be effectively weakened. The middle part of the slider body 2 is provided with an oil chamber 4, and the inner walls of the slider body 2 near the two ends of the oil chamber 4 are inlaid with magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com