Method for evaluating ripening degree of sturgeon meat based on flavor fingerprint spectrum and partial least square regression analysis

A partial least squares, flavor fingerprinting technology, applied in the evaluation of sturgeon meat maturity, can solve problems such as affecting taste, microbial infection, and more influence, achieving strong innovation and practicability, high detection efficiency, and short detection time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Assay method of the present invention is specifically summarized as follows:

[0034] (1) Sample processing

[0035] After thawing in running water for 0.5 h, the frozen male Russian sturgeon was cut and sampled along the direction of the spine, and the fillets were shaped into 3cm×3cm×1cm and washed with sterile water.

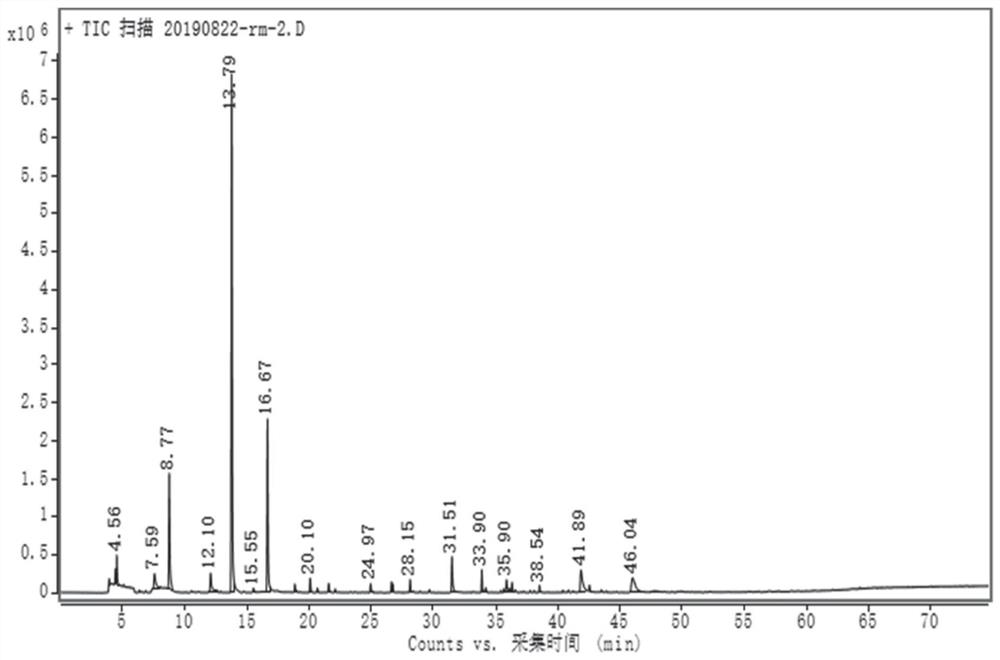

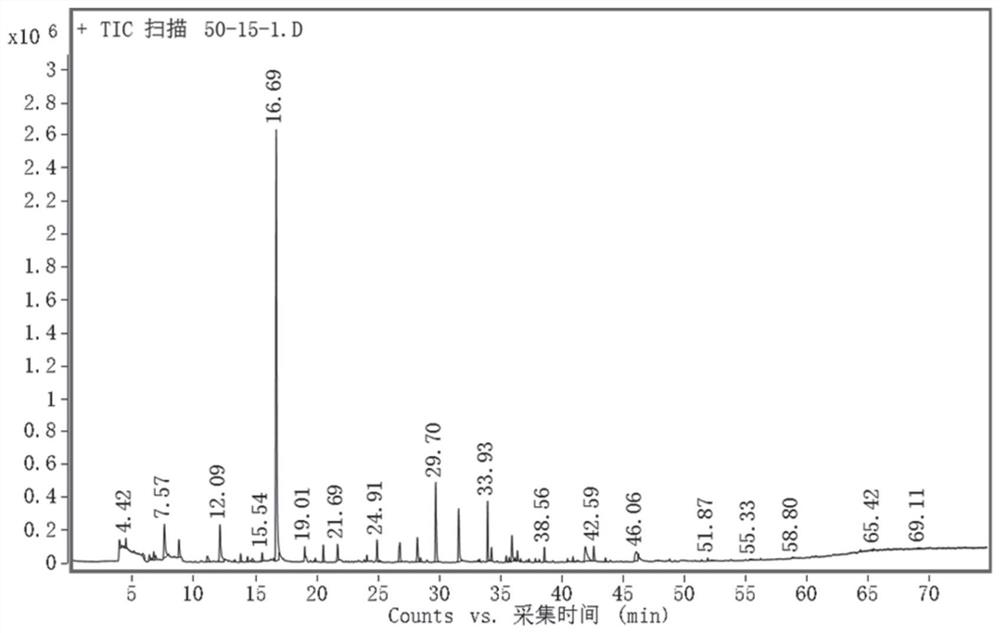

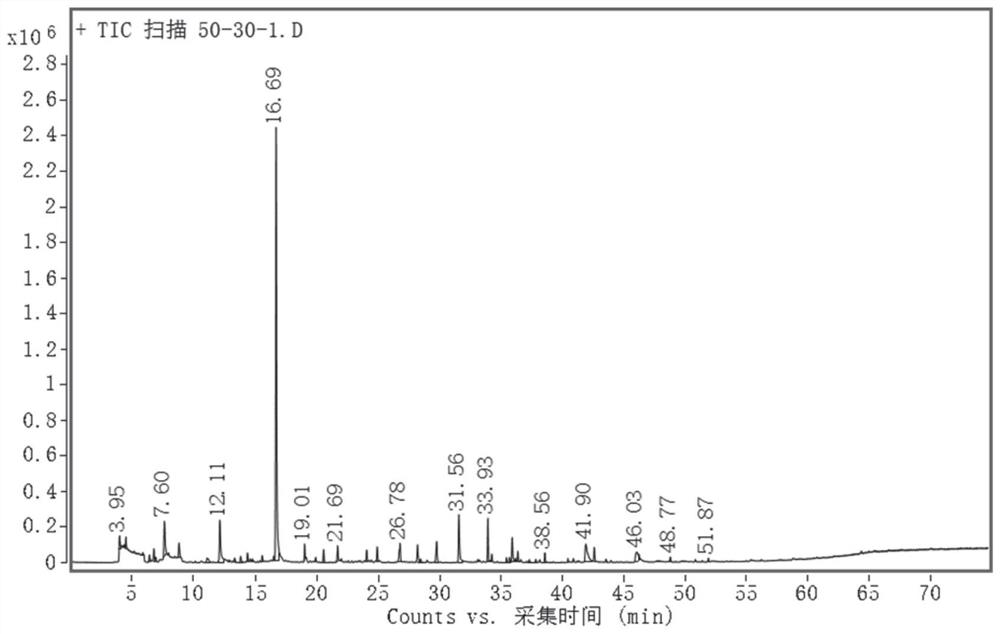

[0036]Set the temperature of the vacuum pot to 50°C (-880bar), 70°C (-700bar), and 100°C (1.01bar), which are the boiling points under the corresponding vacuum degree. Completely immerse the fish fillets in water, take them out after heating for 15min and 30min respectively, and vacuum-pack them with PA+CPP composite packaging bags. The raw meat sample group is directly vacuum-packed with PA+CPP composite packaging bags after being washed with sterile water, and they are numbered RAW, LTVH5015, LTVH5030, LTVH7015, LTVH7030, and TC10015.

[0037] (2) GC-MS (gas chromatography-mass spectrometry) determination

[0038] ①Extraction of volatile flavor su...

Embodiment 2

[0071] Assay method of the present invention is specifically summarized as follows:

[0072] (1) Sample processing

[0073] After thawing in running water for 0.5 h, the frozen male Russian sturgeon was cut and sampled along the direction of the spine, and the fillets were shaped into 3cm×3cm×1cm and washed with sterile water.

[0074] Set the temperature of the vacuum pot to 50°C (-880bar), 70°C (-700bar), and 100°C (1.01bar), which are the boiling points under the corresponding vacuum degree. Completely immerse the fish fillets in water, take them out after heating for 15min and 30min respectively, and vacuum-pack them with PA+CPP composite packaging bags. The raw meat sample group is directly vacuum-packed with PA+CPP composite packaging bags after being washed with sterile water, and they are numbered RAW, LTVH5015, LTVH5030, LTVH7015, LTVH7030, and TC10015.

[0075] (2) GC-MS (gas chromatography-mass spectrometry) determination

[0076] ①Extraction of volatile flavor sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com