Power plant inspection method based on wireless Bluetooth equipment

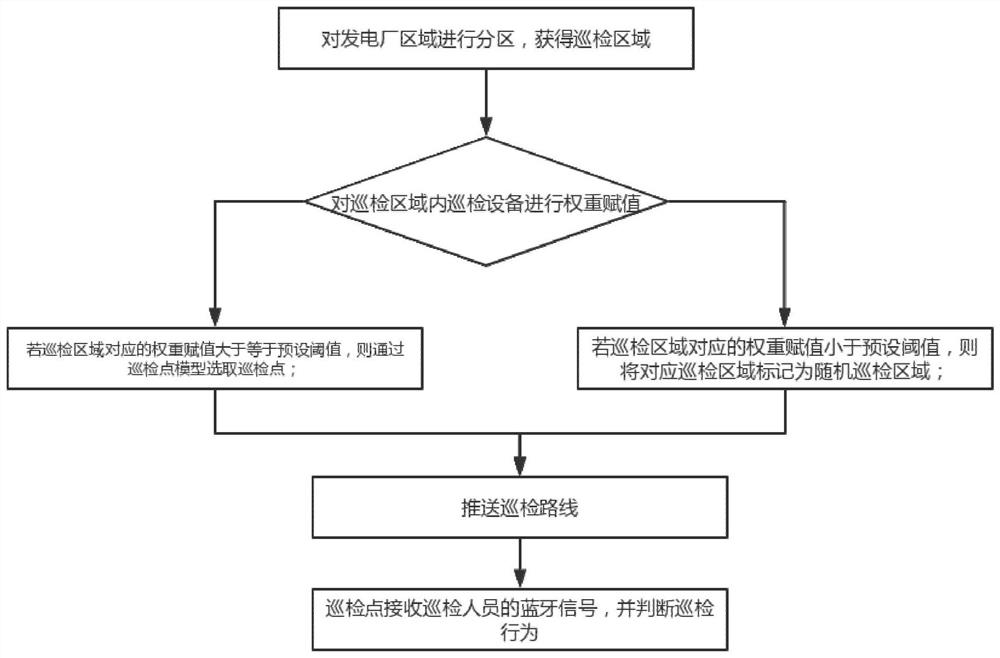

A technology for Bluetooth devices and power plants, applied in the field of artificial intelligence, can solve problems such as non-standard inspection methods, inconvenient statistics, and inability to assess, so as to improve inspection efficiency, production safety and personnel safety, and improve production work. Efficiency, the effect of reducing statistical complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

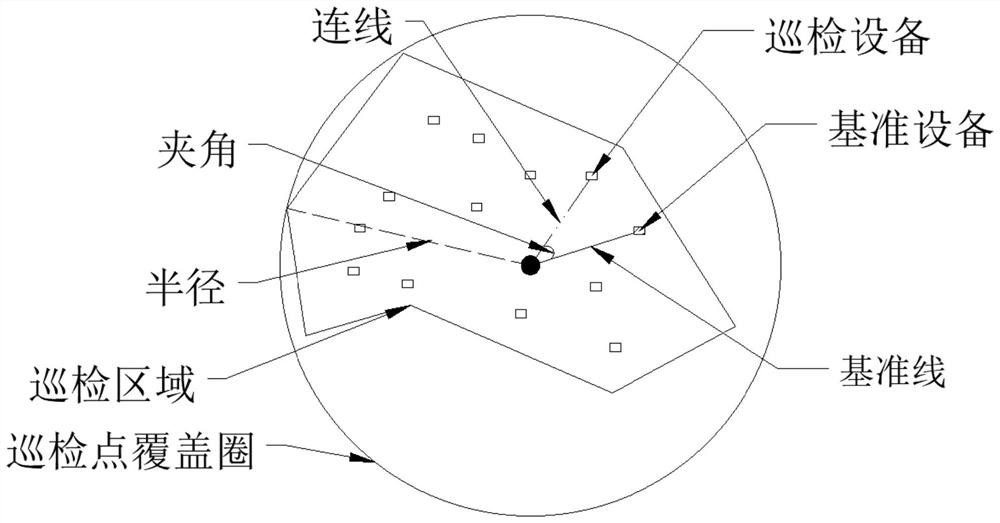

[0098] Collect several satellite photos of the power plant area, and divide several satellite photos of the power plant area into the first area and the second area;

[0099] In the specific implementation, several satellite photos of the power plant area can be satellite photos of the same power plant area in different time periods in the same region, or satellite photos of power plant areas in different regions; by selecting satellite photos, the power plant area can be obtained to the greatest extent. Topographic map, which ensures the integrity of the inspection area;

[0100] Exemplarily, it is possible to select several satellite photos of the power plant area corresponding to different time periods within 3 years of the power plant, and realize the division of the satellite photos of the power plant area by manual labeling, wherein the division results are the first area and the second area;

[0101] Among them, the first area is an irrelevant area, and the second area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com