Coal-gangue multistage-separation system with impact mechanisms arranged on side wings of rubber belts

An impact mechanism and multi-stage separation technology, applied in the direction of solid separation, sorting, screening, etc., can solve the problems of complex mechanical structure, slow separation speed, waste of equipment and energy, etc., to simplify the mechanical structure, prevent energy waste, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be described clearly and completely in further detail below in conjunction with the accompanying drawings in the embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

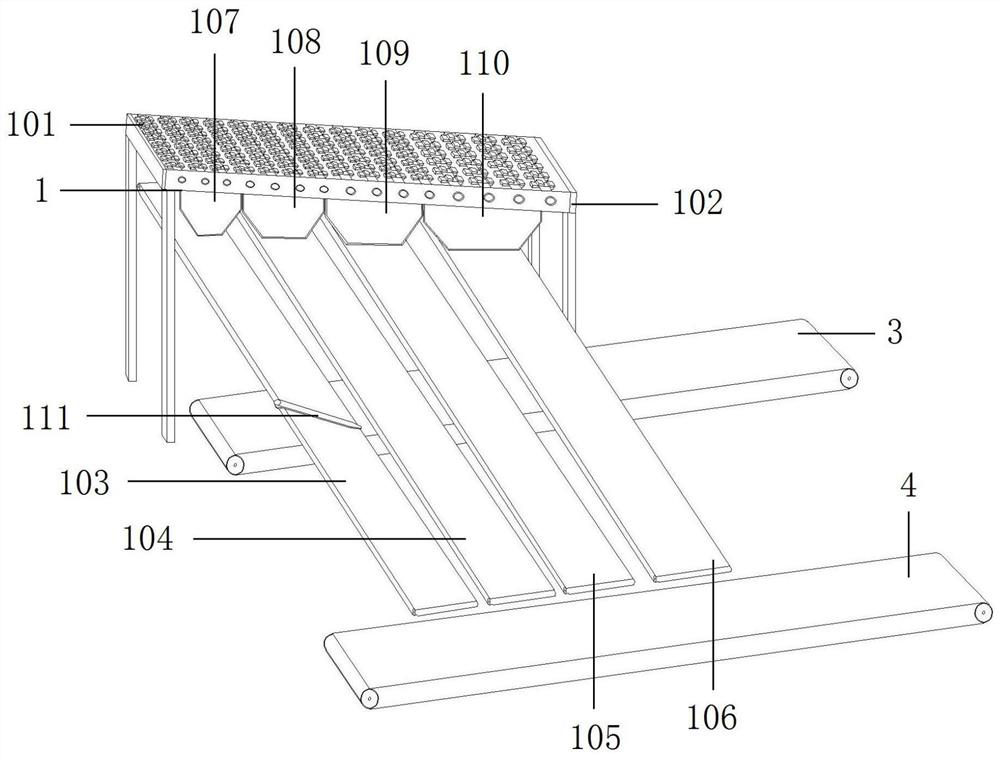

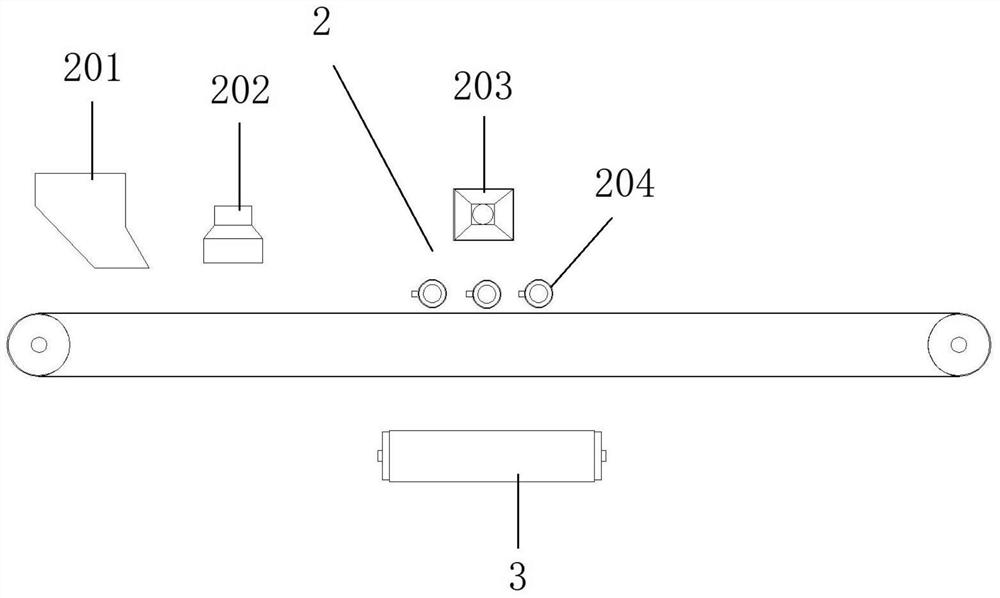

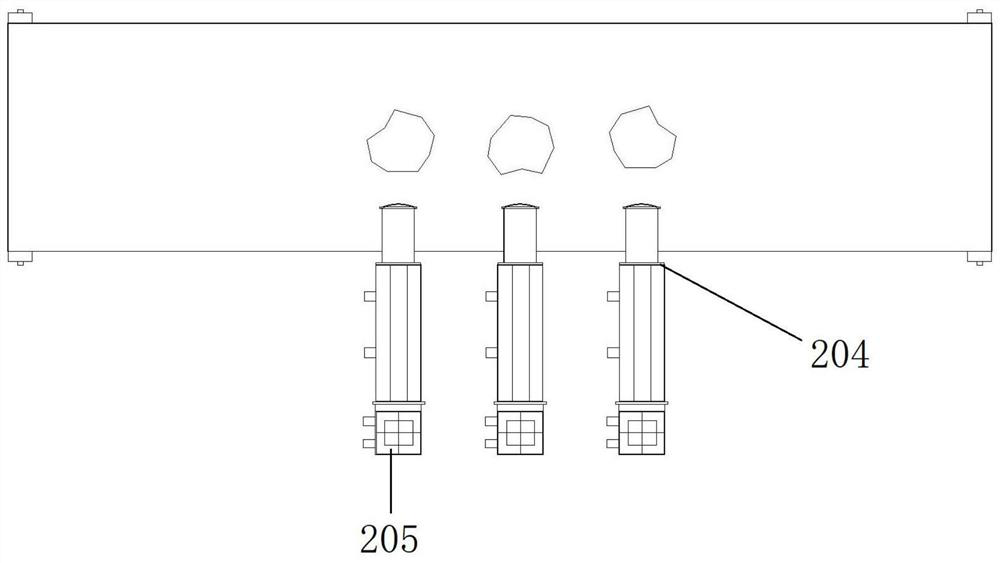

[0030] Such as Figure 1-5 As shown in the figure, an impact mechanism is arranged on the side of the tape and the system for multi-stage separation of coal gangue includes a classification transportation device 1 and a coal gangue separation device 2. The roller screen frame 102 provided by the classification transportation device 1 is installed at the outlet of the raw coal transportation system At the coal mouth, a number of roller screens 101 are installed on the roller screen frame 102 and the roller screen frame 102 is inclined to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap