Automatic press-fitting equipment for plunger pump

A plunger pump, automatic technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of high labor cost, low installation efficiency, missing gaskets and star rings, etc., to reduce labor costs, Improve installation efficiency and solve the effect of missing and wrong installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

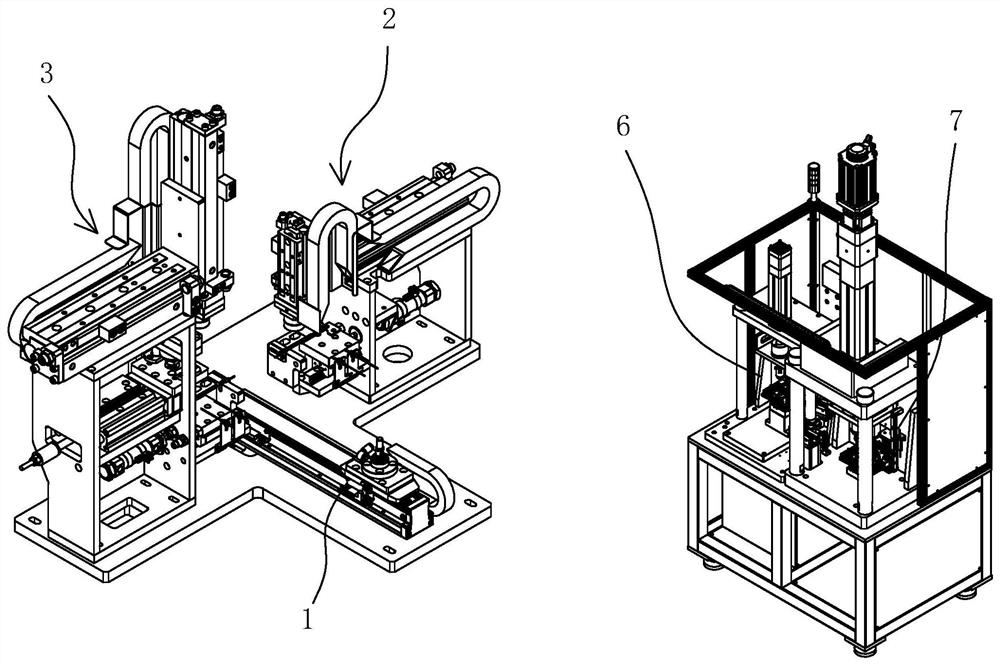

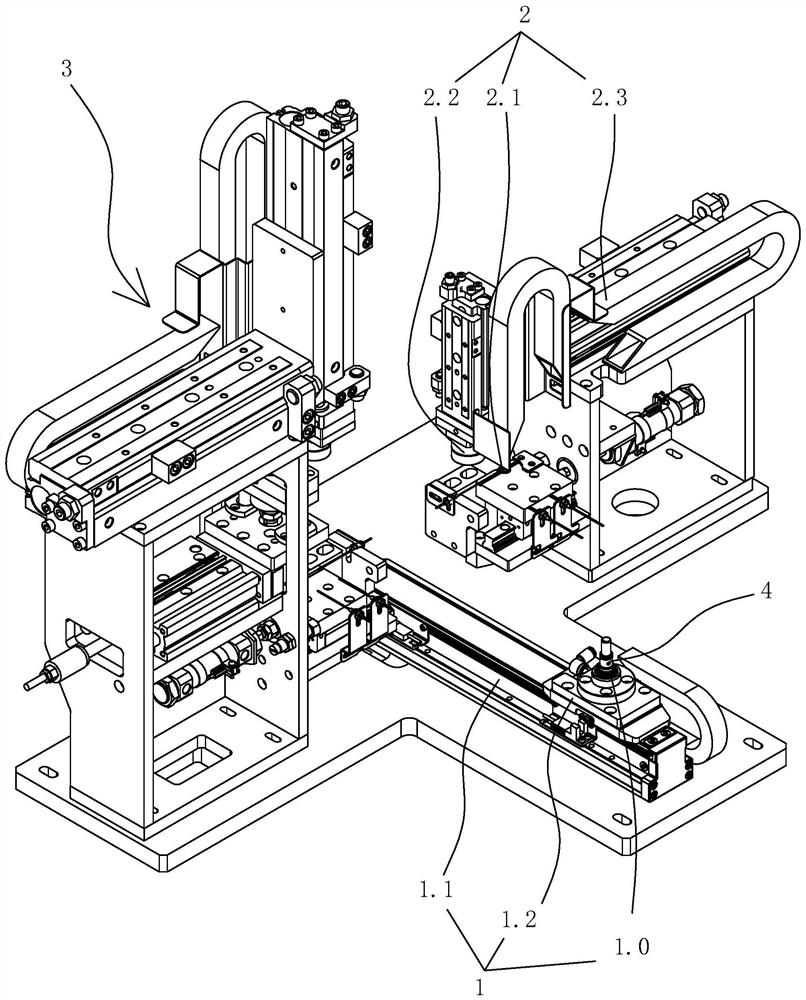

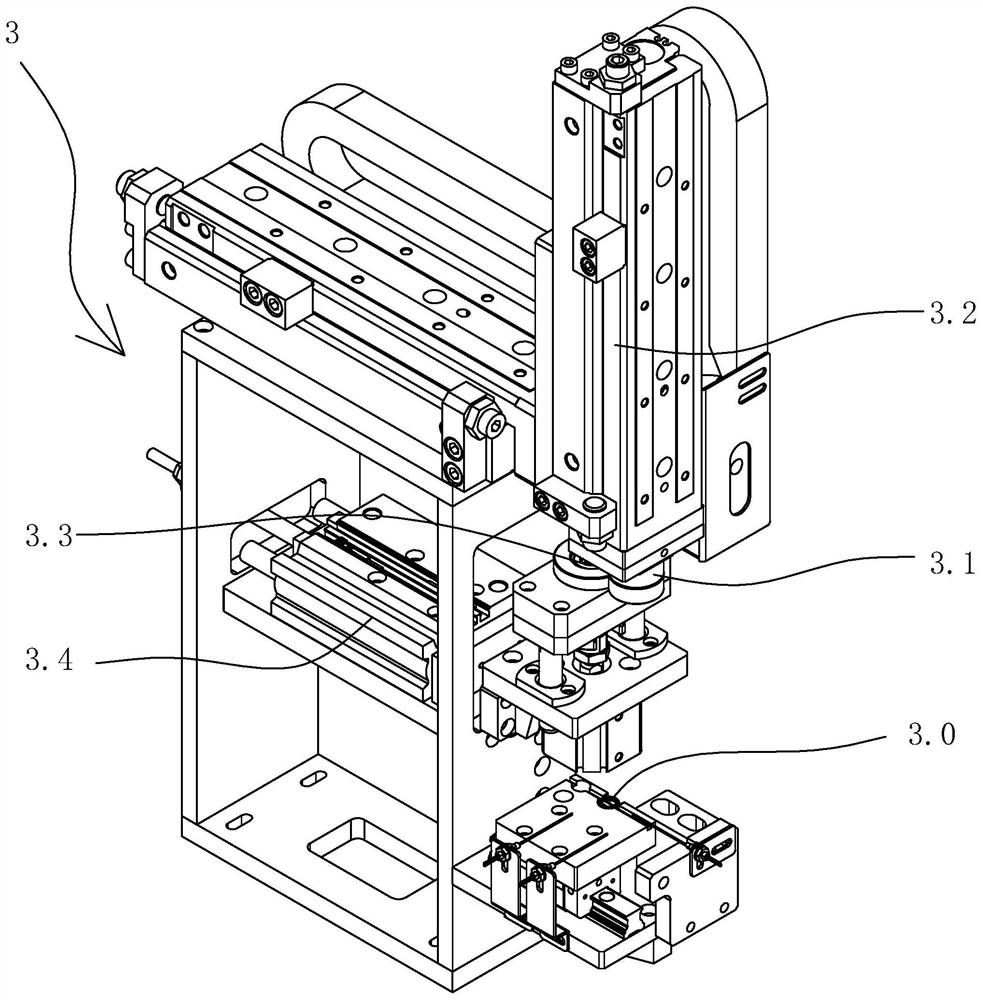

[0054] Specific embodiment one: as figure 1 , figure 2 , image 3 As shown, an automatic press-fitting equipment for plunger pumps, including frame, star ring and gasket assembly tooling, plunger pump press-fitting tooling 6 and plunger pump riveting tooling 7, star-shaped ring and gasket assembly tooling , plunger pump press-fitting tooling and plunger pump riveting tooling are installed on the frame.

[0055] Star ring and gasket assembly tooling includes plunger pump installation station 1, gasket assembly mechanism 2 and star ring assembly mechanism 3. The plunger pump installation station is provided with a vertical positioning hole 1.0, and the vertical positioning hole is used for positioning the plunger pump 4.

[0056] The gasket assembly mechanism 2 includes a gasket positioning groove 2.1, a gasket vacuum suction head 2.2 and a gasket assembly manipulator 2.3. The gasket vacuum head is used to pick up gaskets. The gasket assembly manipulator is used to move t...

specific Embodiment 2

[0075] Specific embodiment two, all the other structures in the present embodiment refer to specific embodiment one, and its difference is:

[0076] like Image 6 As shown, the star-shaped ring vacuum suction head 3.1 includes a star-shaped ring suction head, an annular suction groove 3.11 arranged on the lower end surface of the star-shaped ring suction head, and a suction pump that is arranged in the star-shaped ring suction head and communicates with the annular suction groove. Vacuum channels 3.10. When the star-shaped ring vacuum suction head absorbs the star-shaped ring, the annular suction groove is aimed at the end face of the star-shaped ring, and the end face of the star-shaped ring covers the annular suction groove. In this way, the annular suction groove is in a negative pressure state through the vacuuming channel. Therefore, the star-shaped ring is adsorbed, and the adsorption strength is good, and it is not easy to fall off.

[0077] A star-shaped ring limitin...

specific Embodiment 3

[0078] Specific embodiment three, all the other structures in the present embodiment refer to specific embodiment two, and its difference is:

[0079] like Figure 7 , Figure 8 , Figure 9 As shown, a plunger pump automatic press-fitting equipment also includes a leak-proof packing mechanism 5.

[0080] The vacuum channel 3.10 includes a vertical transfer channel 3.13 arranged in the star-shaped ring suction head, a vertical suction channel 3.14 located above the vertical transfer channel, and a connecting channel 3.15 connecting the vertical transfer channel and the annular suction groove . The lower end of the vertical suction channel communicates with the upper end of the vertical transfer channel, and the inner diameter of the vertical transfer channel is larger than the inner diameter of the vertical vacuum channel. The star ring vacuum suction head draws the air out of the annular suction groove through the vertical suction channel.

[0081] The anti-leakage instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com