Automatic mattress bagging machine

A bagging machine and automatic technology, which can be used in household appliances, applications, interior decoration and other directions, can solve the problem of difficult bagging of artificial mattresses, and achieve the effect of good force point, smooth and stable movement, and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

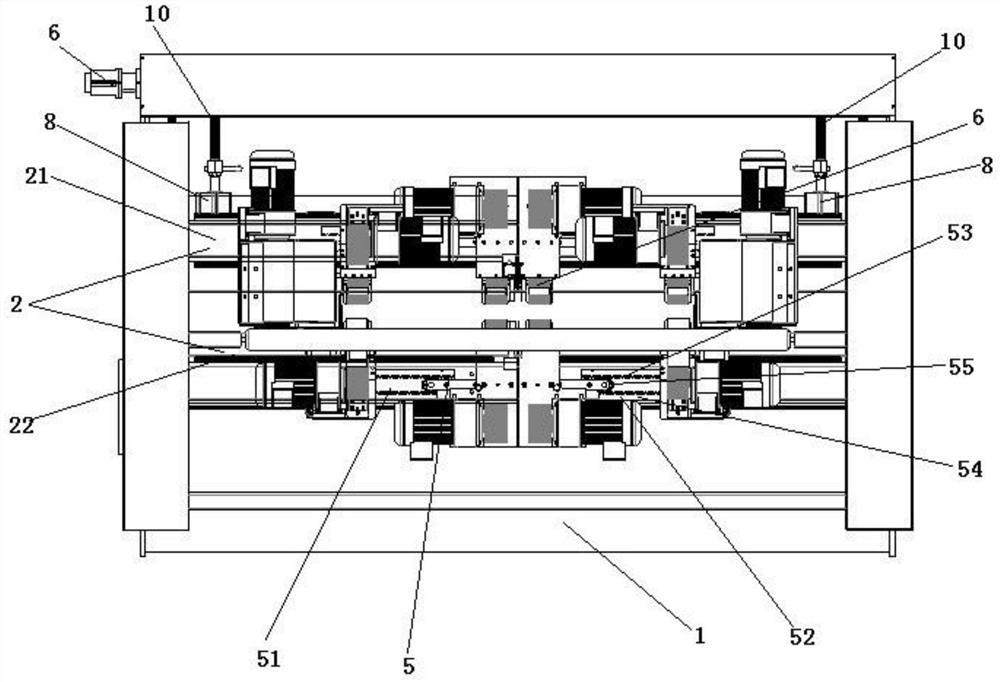

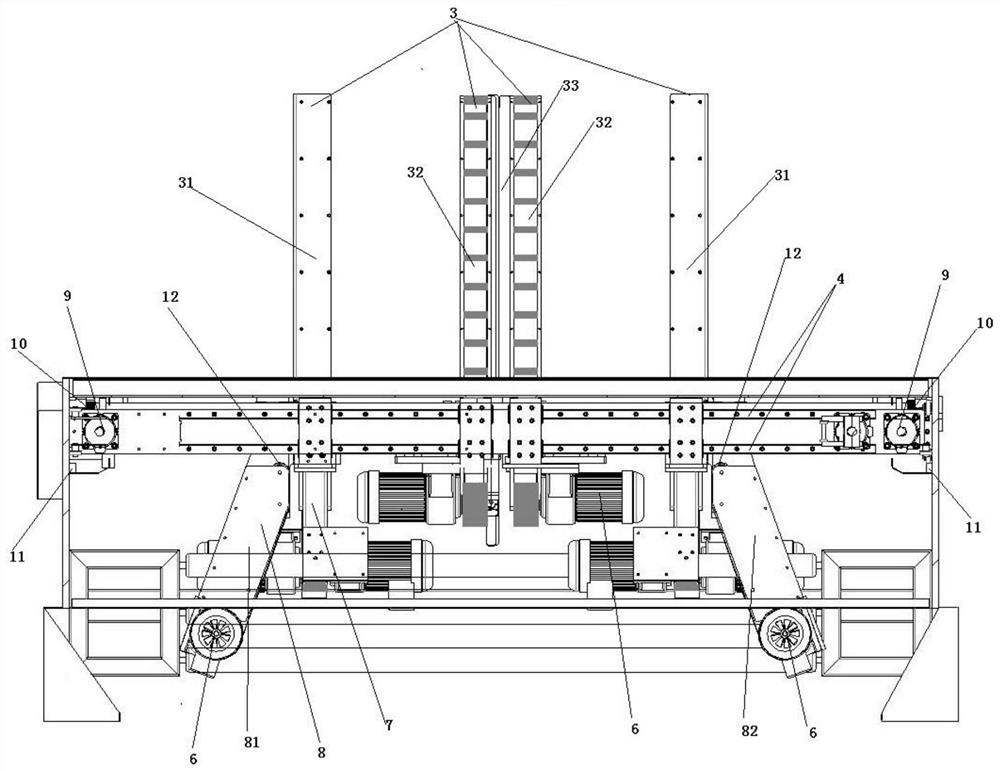

[0020] Such as figure 1 and figure 2 As shown, a mattress automatic bagging machine includes a frame 1, a beam 2, a swing arm 3, a wire rail 4, a connecting rod device 5 and a servo motor 6, the beam 2 includes an upper beam 21 and a lower beam 22, and the upper beam 21 and the lower crossbeam 22 are arranged in parallel inside the frame 1, and the upper crossbeam 21 and the lower crossbeam 22 are correspondingly provided with 4 pairs of swing arms 3, a total of 8 swing arms 3, and the swing arms 3 are respectively provided with guide belts 7, Driven by 8 servo motors 6 respectively, the line rail 4 and the connecting rod device 5 are arranged on the beam 2 , and the four pairs of swing arms 3 are respectively installed on the line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com