Electric supercharging Miller cycle engine power system

A Miller cycle, electric supercharging technology, applied in engine control, combustion engine, machine/engine, etc., can solve problems such as affecting power output, application range and thermal efficiency limitations, and less applicable working conditions

Pending Publication Date: 2021-08-03

胡勤伟

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the supercharger will affect the power output at high speed, and the efficiency is low

[0005] Existing supercharging technology cannot take into account the performance and thermal efficiency at low and high speeds at the same time. It is applicable to few working conditions, the efficiency is low under non-ideal working conditions, and the supercharging intensity cannot be flexibly adjusted.

These disadvantages make the traditional supercharging technology have some limitations in the scope of application and thermal efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0031] The present invention can output mechanical power and electric power to the outside at the same time, and can also output mechanical power or electric power separately. The invention can be used in oil-electric hybrid vehicles and high-efficiency generators.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

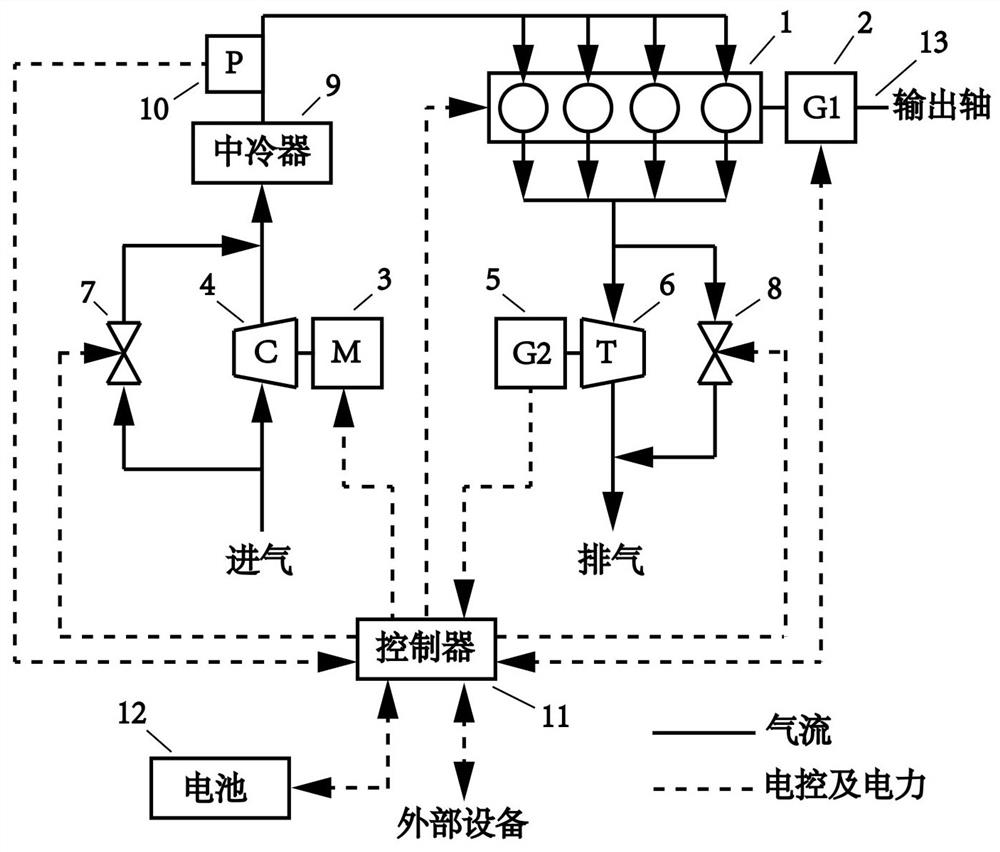

The invention discloses an electric supercharging Miller cycle engine power system which comprises a Miller cycle engine, a first generator, an electric supercharger, an air inlet bypass valve, an intercooler, a pressure sensor, a turbine generator, an exhaust bypass valve, a controller, a battery and a power output shaft. The electric supercharger is composed of a motor and a gas compressor, and the turbine generator is composed of a turbine and a second generator. According to the electric supercharging Miller cycle engine power system, the electric supercharging technology is adopted, and mechanical power and electric power can be output outwards at the same time. The system is simple in structure, few in mechanical parts and high in reliability; and control is flexible, system response is fast, and thermal efficiency is high.

Description

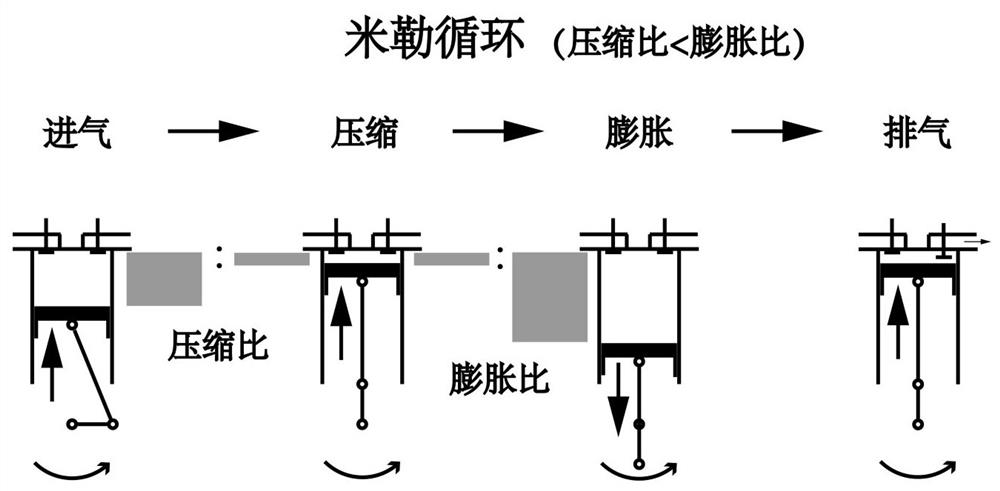

technical field [0001] The invention belongs to the technical fields of engines and electric motors, and relates to an electric supercharged Miller cycle engine power system. Background technique [0002] Supercharging refers to the compression of the gas entering the engine. The purpose is to increase the intake air volume of the engine without increasing the engine displacement, thereby increasing the power and torque of the engine. The commonly used boosting technologies for engines are turbocharging and supercharging. [0003] Turbocharging is a technology that uses the exhaust gas from the engine to impact the turbine to rotate it, and then drives the compressor to compress the intake air. The capacity of turbocharging is related to the amount of exhaust gas discharged from the engine. When the engine speed is low, the turbocharging capacity is insufficient. At the same time, there is also aerodynamic hysteresis in the turbocharger, which leads to a slow response of t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F02D23/00F02B29/04F02B37/18F01D15/10

CPCF02D23/00F02B29/04F02B37/183F01D15/10Y02T10/12

Inventor 胡勤伟

Owner 胡勤伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com