A deflector and injector capable of improving the synchronization of propellant filling

A deflector and synchronicity technology, applied in the field of deflectors and injectors, can solve the problems of reduced filling synchronicity, long stroke, and reduced working stability of the injector, so as to improve working stability and production cost. Low, shortened time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to illustrate the technical solution of the present invention more clearly, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

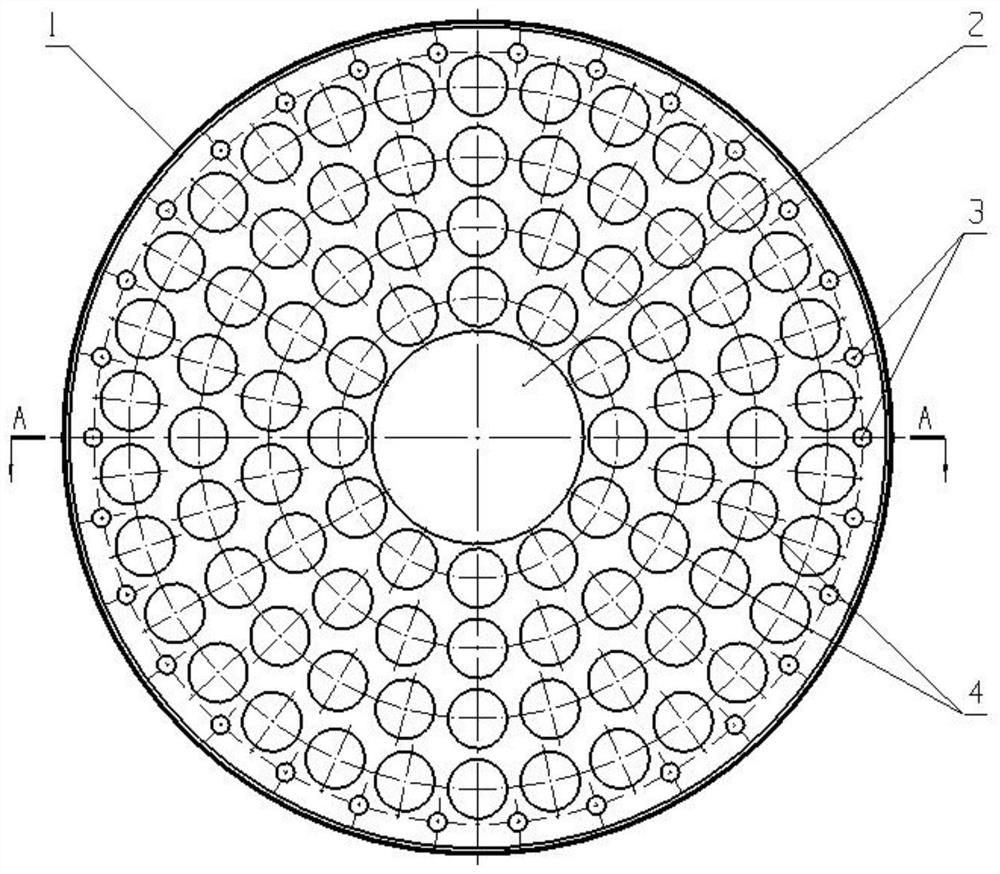

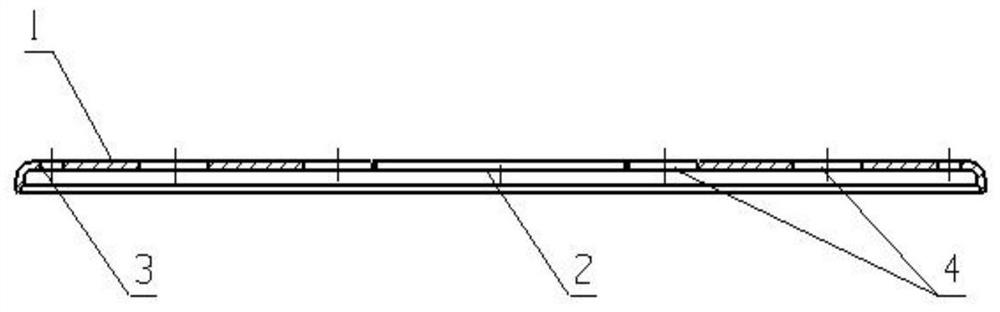

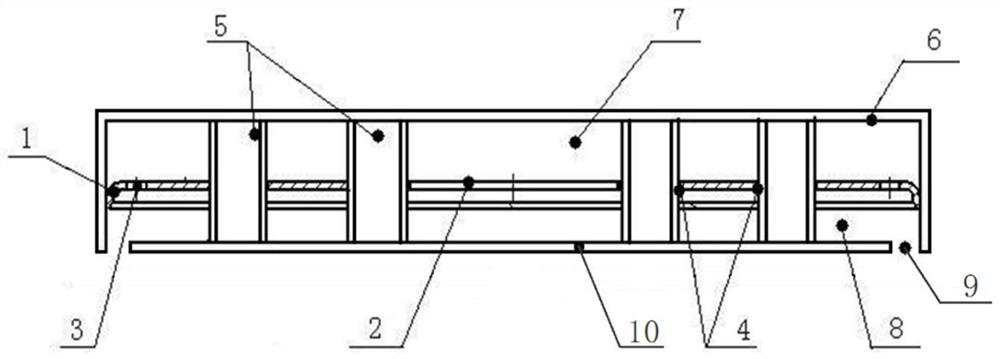

[0035] The present invention can improve the deflector of propellant filling synchronization such as figure 1 and figure 2 As shown, the deflector 1 includes a deflector body, a central hole 2 , a side area flow hole 3 and a nozzle installation hole 4 . Wherein, the deflector body is a porous punched disc structure, the central area of the deflector body is provided with a central hole 2, and the edge area is uniformly provided with a plurality of side-distributing flow holes 3 along the circumference, and a plurality of nozzle installation holes 4 are provided in the remaining areas. Nozzle installation holes 4 are arranged in 4 layers, the number of nozzle installation holes 4 in the innermost layer is 12, and the number of nozzle installation holes 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com