Spring disassembling and assembling tool

A tool and torsion spring technology, applied in the field of parts disassembly, can solve the problems of time-consuming and laborious spring disassembly, and achieve the effects of improving reliability, simple structure and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

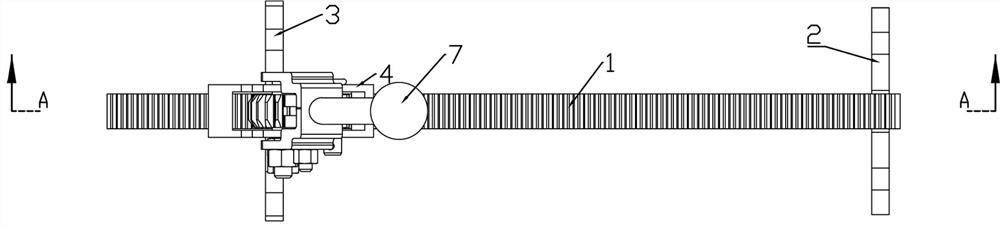

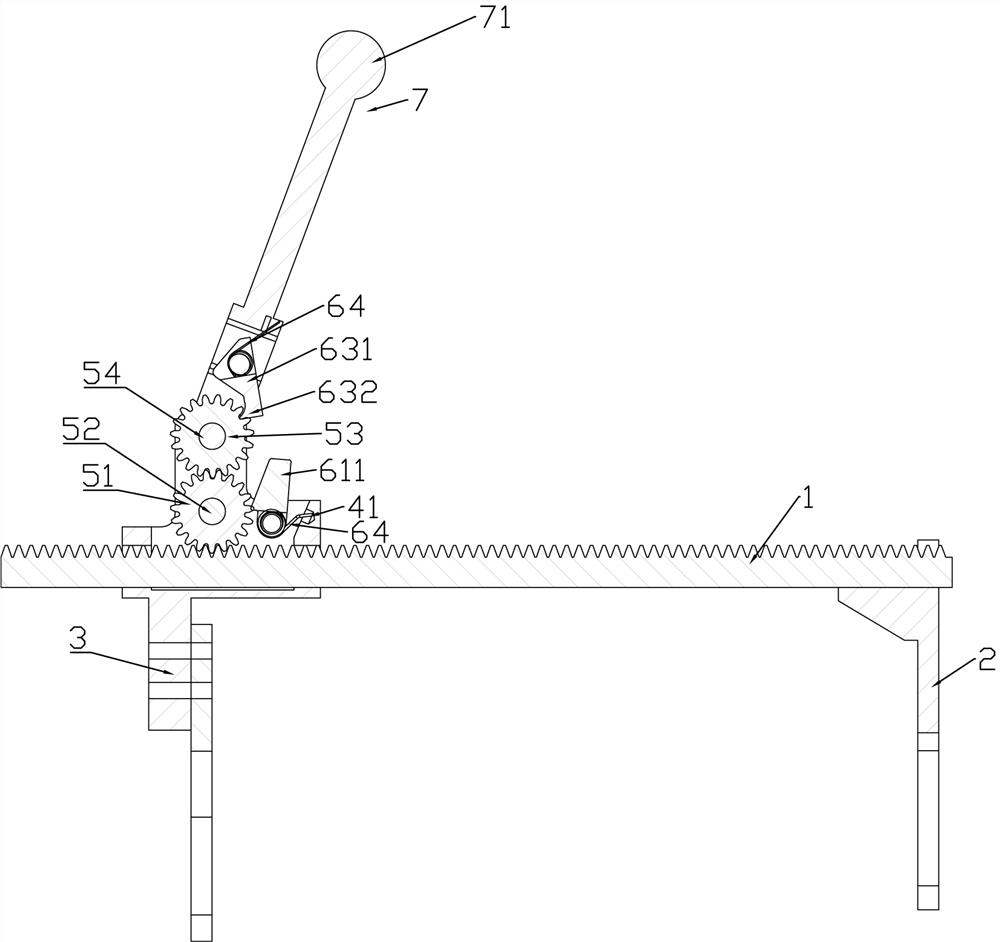

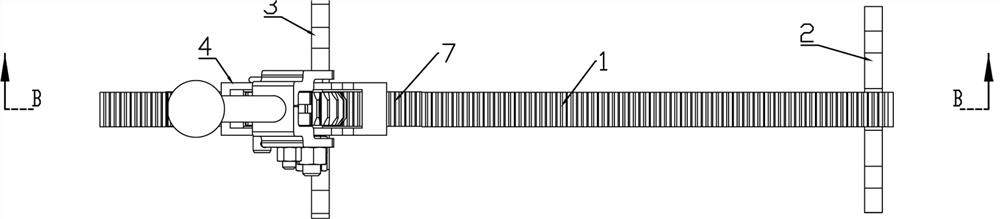

[0038] Embodiment 2: A spring dismounting tool, including two claws for clamping the spring from the spring helical gap and a moving mechanism that drives the two claws to move relative to each other. The moving mechanism includes a rack guide rail 1 and a gear rack The gear structure 5 meshed with the guide rail 1, one of the two claws is slidably assembled on the rack guide rail 1 through the sliding seat, and the other fixed claw 2, the gear structure 5 is assembled on the sliding seat 4 through the rotation of the gear shaft, and the spring The dismounting tool also includes a drive mechanism for driving the gear structure to rotate. The drive mechanism is a manual drive mechanism, and the manual drive mechanism includes a wrench 71 fixed to the second rotating shaft 54 and rotatably matched with the sliding seat. The tension spring and the compression spring can be disassembled at the same time, and the structure is simple. By setting the wrench 71, it can be suitable fo...

Embodiment 3

[0039] Embodiment 3: In one embodiment of the present invention, as Figure 5-7 As shown, both the first pawl and the second pawl include a pawl main body 631 and a locking head arranged at one end of the pawl main body 631. The locking head is in the form of a flat surface, an inclined surface, and a connection with the main body. Triangular shape, the ratchet main body can move along the radial direction of the first gear 51 or the second gear 53 to insert or disengage the locking head from the tooth gap of the first gear 51 or the second gear 53 . The first ratchet 611 and the second ratchet are provided with the torsion spring 64 that cooperates with the rotation of the first ratchet and the second ratchet; the inside of the slide seat 4 is provided with a housing portion 41 that matches each torsion spring 64, and the torsion spring 64 includes a curved positioning portion, the two ends of the positioning portion extend to form the first end and the second end of the tors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com