Wood veneer texture processing technology and wood veneer texture processing device

A technology of processing device and processing technology, applied in printing device, printing process, post-processing of printing, etc., can solve the problems of easy falling off of stickers, short service life, poor use effect of veneer, etc., to improve the effect and distribution of transfer printing uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

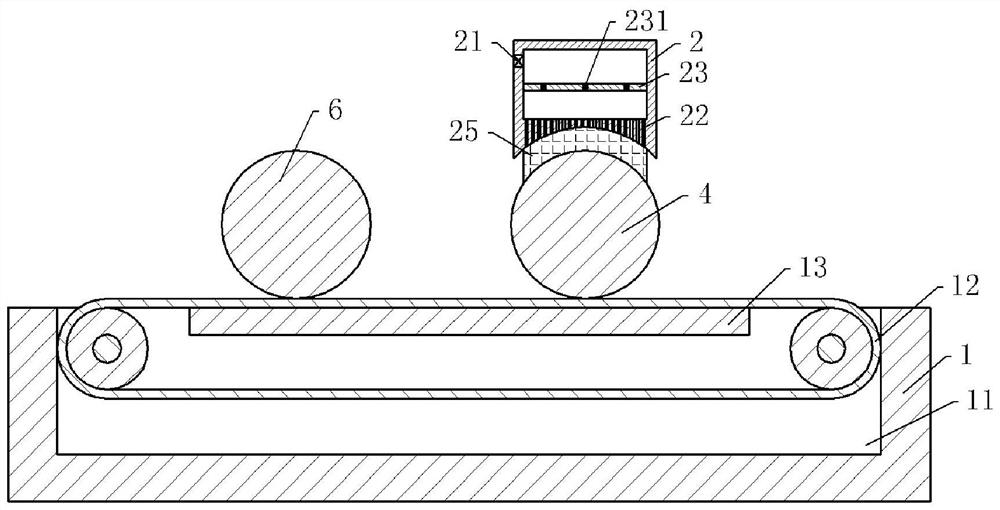

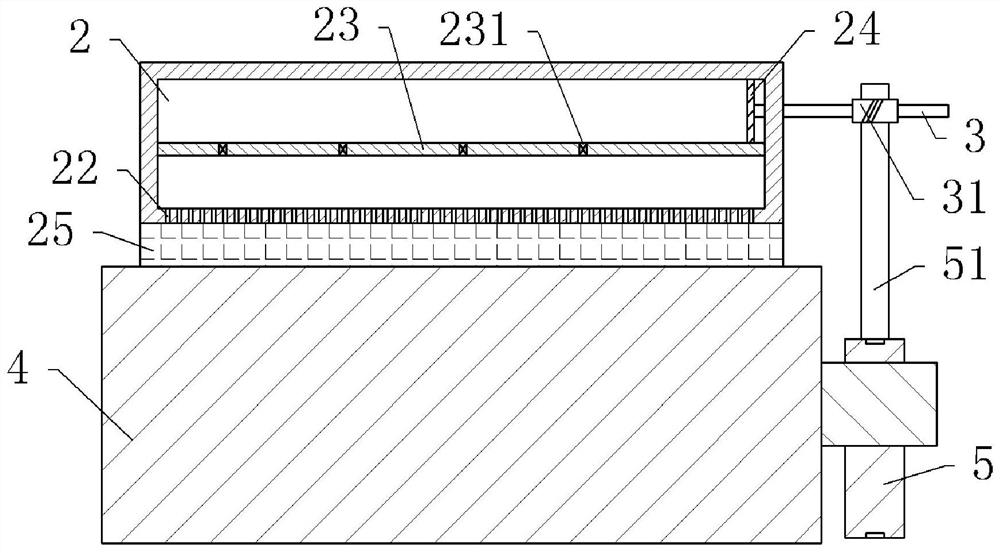

[0033] A veneer texture processing technology is completed by using a veneer texture processing device. The veneer texture processing device is basically as figure 1 As shown, it includes a frame, a workbench 1 and a liquid storage tank 2 are fixed on the frame, the liquid storage tank 2 is located above the workbench 1, and a horizontal baffle 23 is arranged in the liquid storage tank 2. combine figure 2 As shown, a squeeze plate 24 is slidably connected in the liquid storage tank 2 above the baffle plate 23, and a moving rod 3 is welded to the right side of the squeeze plate 24. The moving rod 3 penetrates the right side wall of the liquid storage tank 2 and The moving rod 3 is threadedly connected to the right side wall of the liquid storage tank 2 . The right part of the moving rod 3 outside the liquid storage tank 2 is connected with a gear 31 through splines, a mounting bracket is fixed on the right side wall of the liquid storage tank 2, and the gear 31 is rotatably ...

Embodiment 2

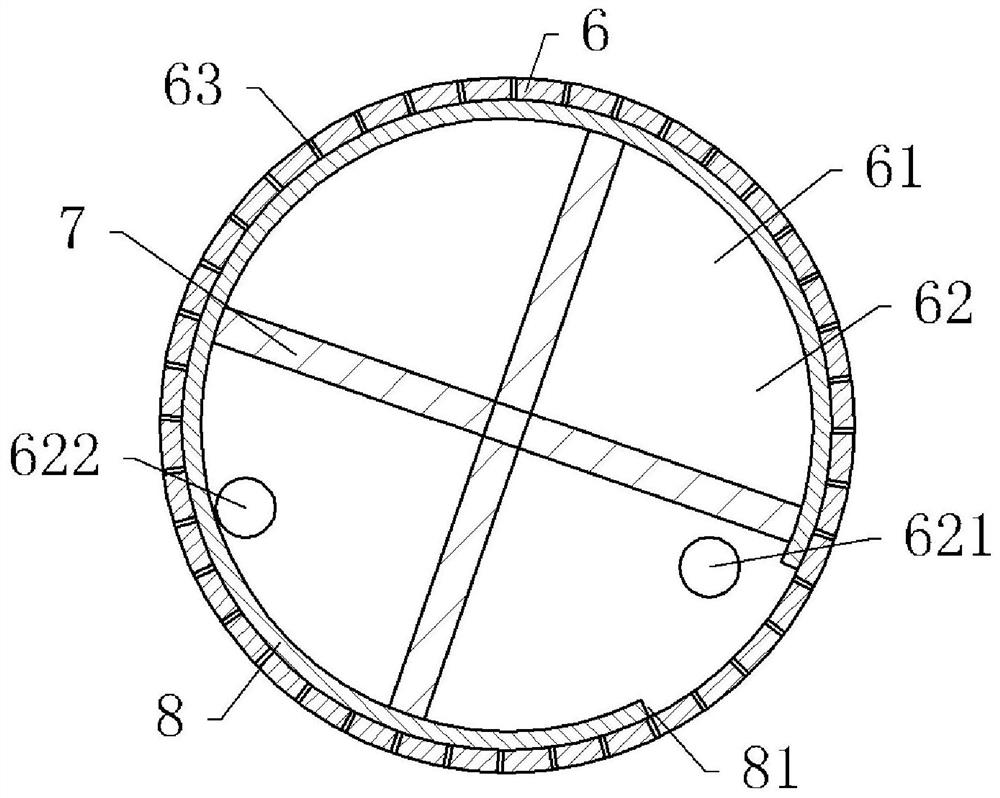

[0048] The only difference between Example 2 and Example 1 is that, as image 3 As shown, in the present embodiment, the pressing roller 6 is provided with a dust suction channel 61, and one end of the dust suction channel 61 can communicate with the outside. A sealing plate 62 is fixed on the frame, the open end of the pressing roller 6 is rotatably connected with the sealing plate 62 , and the sealing plate 62 seals the open end of the pressing roller 6 .

[0049] The dust suction channel 61 is provided with a plurality of partitions 7, one side of the multiple partitions 7 is fixed, one end of the partitions 7 is fixed on the end of the pressing roller 6, and a dust guide space is formed between the adjacent partitions 7. cavity; the pressing roller 6 is provided with a plurality of dust removal holes 63 which are respectively communicated with a plurality of dust guide cavities. The dust suction channel 61 is trapezoidal, and a dust suction port 621 and a dust outlet 622 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap