Flexible comprehensive draw bar suitable for rotorcraft

A technology for a rotorcraft and a tow bar, applied in the field of tow bars, can solve the problems that the tow bar cannot be adjusted, has no interchangeability and versatility, cannot be temporarily replaced, etc., and achieves convenient towing connection work, convenient storage and The effect of transportation and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

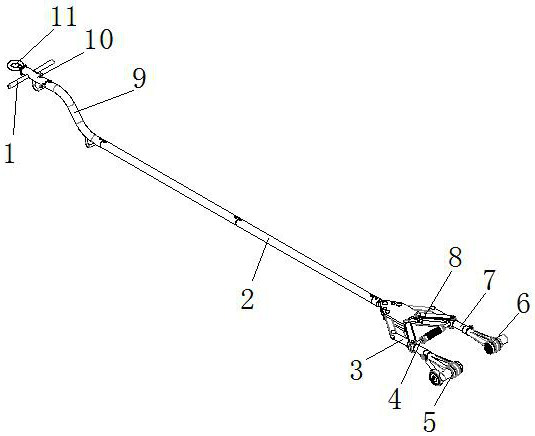

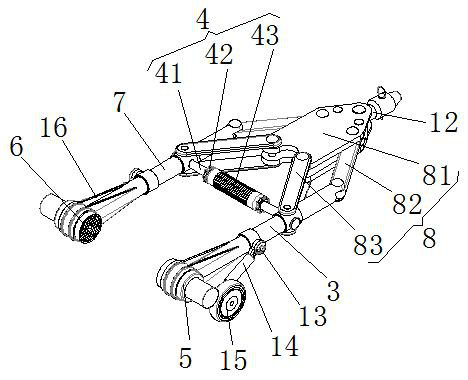

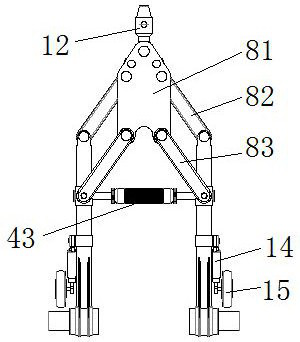

[0022] see Figure 1-5 , the present invention provides a technical solution: a flexible integrated traction rod suitable for rotorcraft, including a traction main rod 2, an adjustment locking mechanism 4, a left synchronous clamping beam 3, a right synchronous clamping beam 7, a left multi-pin Built-in flexible clamper 5, right multi-pin built-in flexible clamper 6, synchronous folding mechanism 8, traction buffer 10 and auxiliary wheel 15, adjustment locking mechanism 4 includes positioning double ear plate 81, left synchronous clamp The holding beam 3 is arranged on the left side of the positioning double ear plate 81, the right synchronous clamping beam 7 is placed on the right side of the positioning double ear plate 81, and the left synchronous clamping beam 3 and the positioning double ear plate 81 are synchronized with the right All be provided with the first movable plate 82 and the second movable plate 83 between the clamping beam 7 and the positioning double ear pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com