Multi-extraction type packaging bag vacuumizing device

A vacuuming device and vacuuming technology, applied in the direction of pressurization/gasification packaging, etc., can solve the problems of increasing the flow of water in the packaging bag, the loss of energy, and the extraction force, so as to improve the quality of packaging and energy loss. Less and longer shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

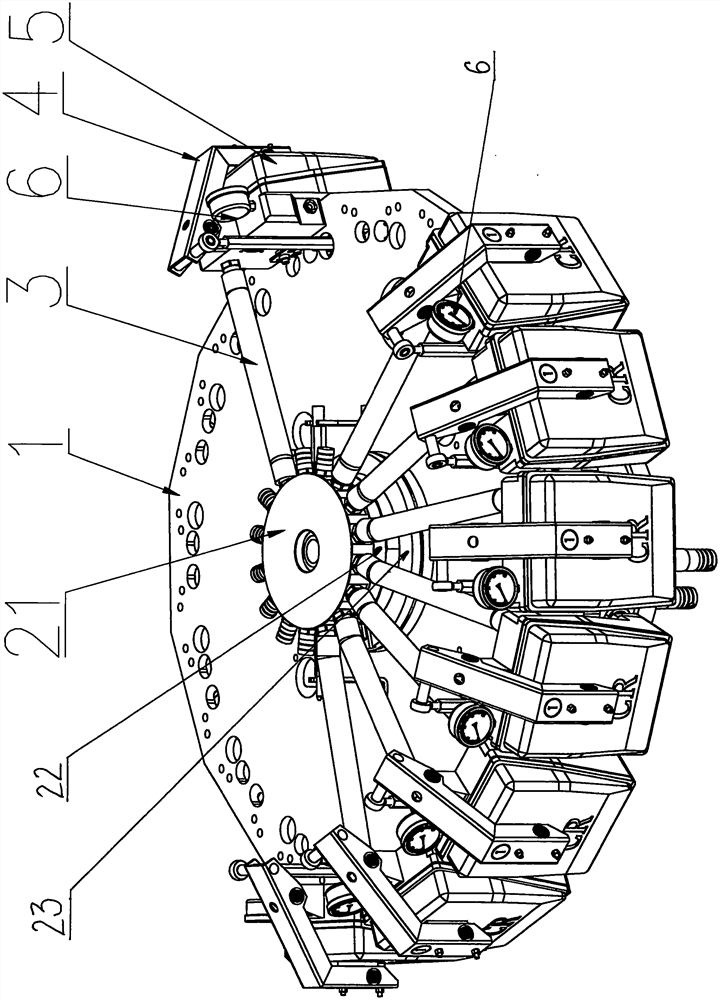

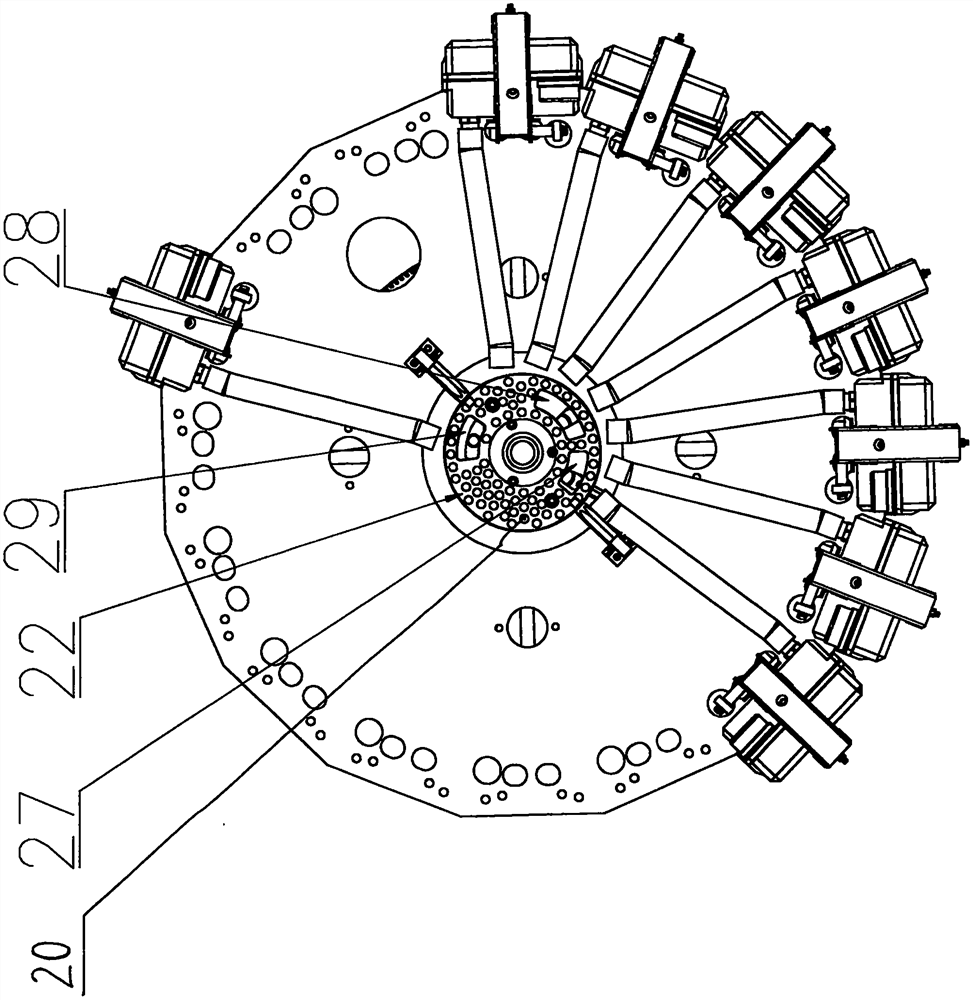

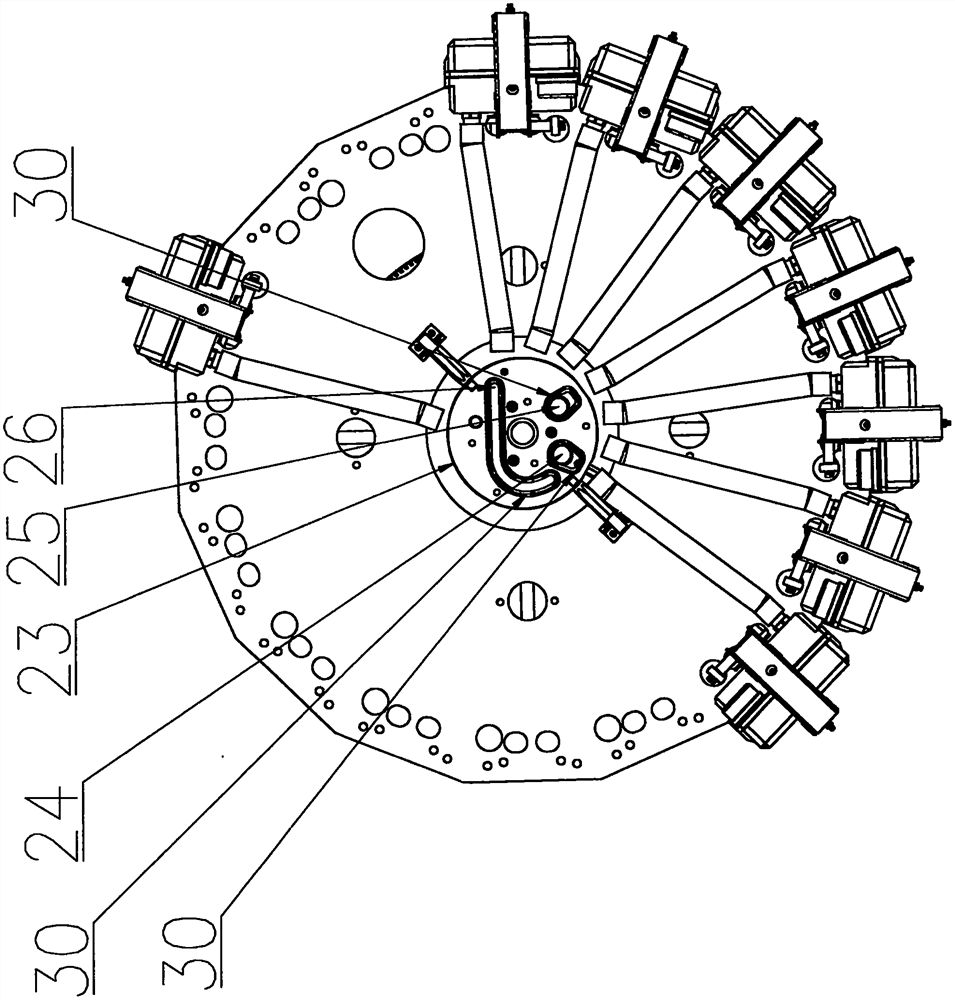

[0011] refer to figure 1 , figure 2 , image 3 It can be seen that the multi-extraction packaging bag vacuum pumping device of the present invention includes a turntable 1 and a gas distribution disc 2, and the gas distribution disc 2 is connected to the vacuum chamber part 4 (corresponding to the number of vacuum tubes) through vacuum tubes 3 (several) , the gas distribution plate 2 is composed of a gas distribution upper plate 21, a gas distribution middle plate 22, and a gas distribution lower plate 23, and a first vacuum passage 24, a second air passage, Vacuumizing channel 25, semi-vacuumizing channel 26, first vacuuming groove 27, second vacuuming groove 28, semi-vacuuming through-hole 29 (several pieces) are also correspondingly provided on the gas distribution intermediate plate 22 . That is: the first vacuum channel 24 corresponds to the first vacuum channel 27 , the second vacuum channel 25 corresponds to the second vacuum channel 28 , and the semi-vacuum channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com