A kind of preparation method of polyether ester random copolymer based on polyethylene furandicarboxylate

The technology of ethylene furandicarboxylate and furandicarboxylate is applied in the field of preparation of polyetherester random copolymers, and can solve the problems of narrow adjustable range of ether bond content, large amount of catalyst, expensive catalyst and the like, Achieve the effects of low cost, high activity, excellent gas barrier properties and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of polyetherester random copolymer based on polyethylene furandicarboxylate: comprising:

[0034] 1) Taking 2,5-furandicarboxylic acid and / or 2,5-furandicarboxylic acid diester and ethylene glycol with a molar ratio of 1:1.1-1:5 as polymerized monomers, in the catalysis of polyvalent organic sulfonic acid catalyst The esterification-etherification reaction is carried out under the reaction temperature of 160-210°C, the reaction time is 2-5h, and the reaction pressure is normal pressure or positive pressure, and the polyetherester oligomer is obtained after the reaction.

[0035] 2) adding an organometallic catalyst to the polyetherester oligomer obtained in step 1) to carry out a polycondensation reaction, the reaction temperature is 210-260° C., the reaction time is 1-6h, and the reaction pressure is less than 50Pa; polyetherester is obtained after the reaction Random copolymer, namely polyethylene furandicarboxylate-co-diglycol.

[0036] Wherein,...

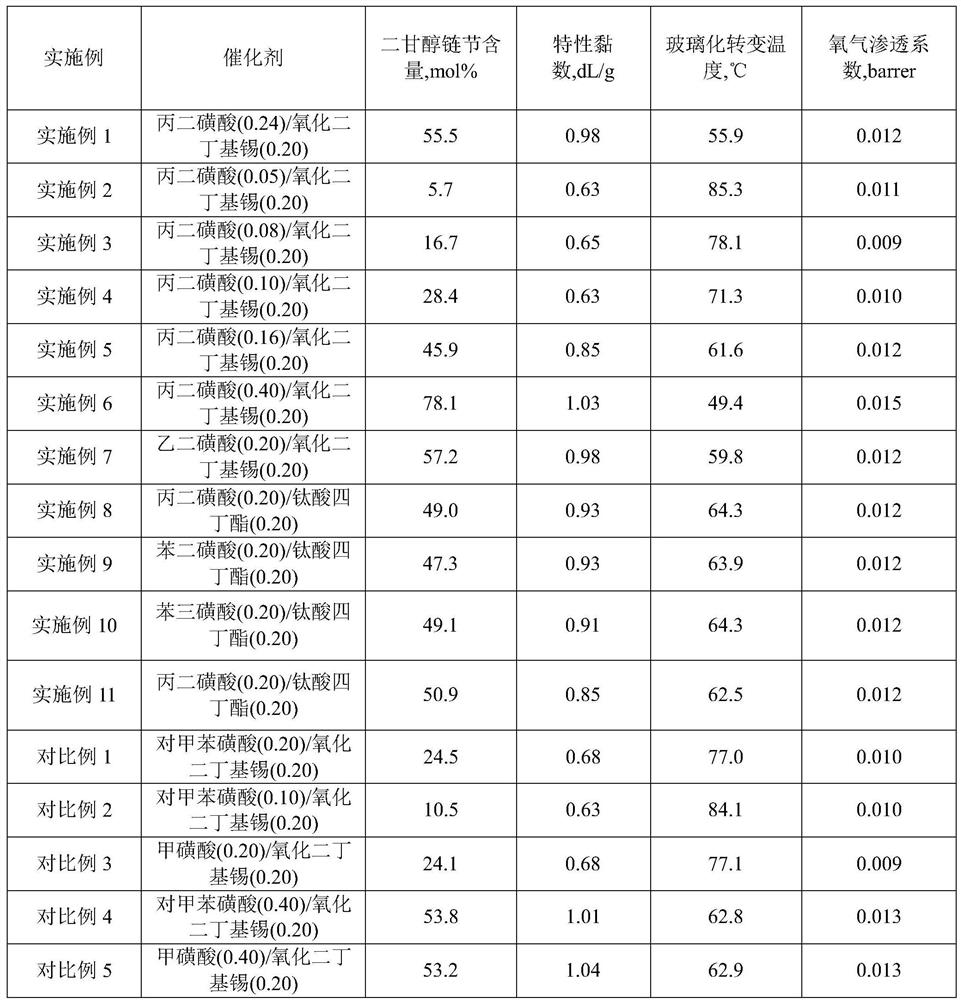

Embodiment 1

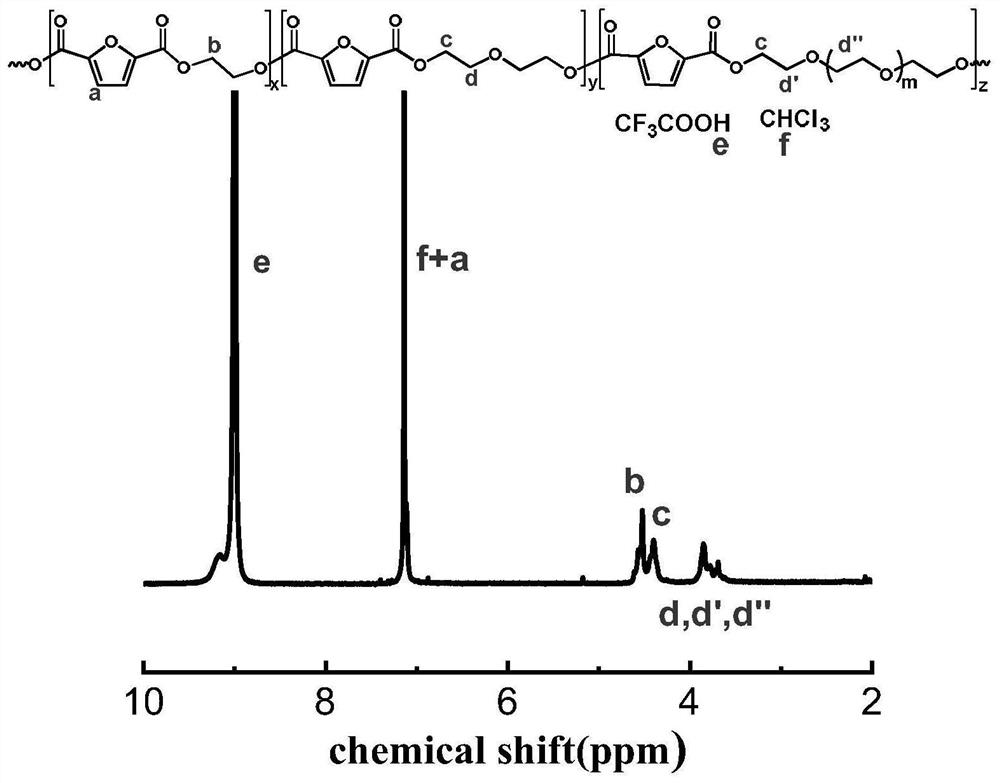

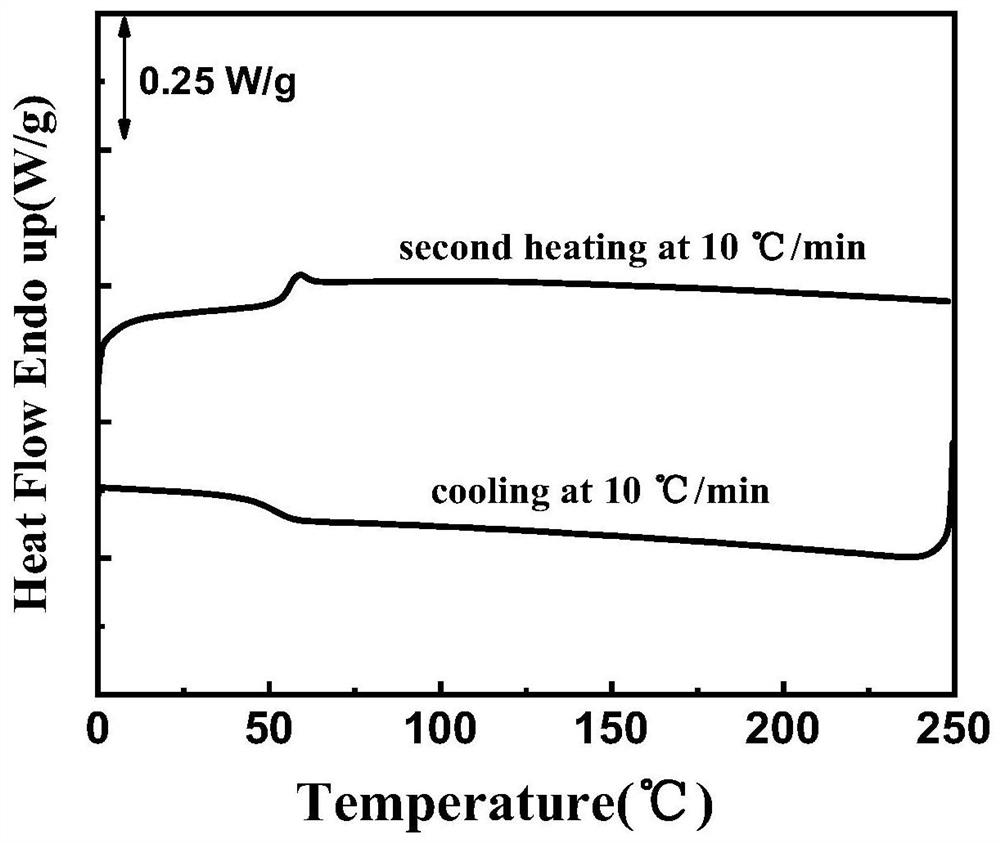

[0048] 30.00g of 2,5-furandicarboxylic acid, 23.85g of ethylene glycol, and 0.072g of propanedisulfonic acid were added to the reactor with nitrogen protection, and the reaction was carried out at 180 °C for 1 h, at 190 °C for 1 h, and at 200 °C to No more water was distilled out to obtain polyetherester oligomer. Then 0.06g of dibutyltin oxide was added to the polyetherester oligomer, and under high vacuum conditions (figure 1 of the samples prepared for Example 1 1 H NMR spectrum; figure 2 DSC curve of the sample prepared for Example 1.

Embodiment 2

[0050] 30.00g of 2,5-furandicarboxylic acid, 23.85g of ethylene glycol, 0.015g of propanedisulfonic acid were added to the reactor with nitrogen protection, and the reaction was carried out at 180 °C for 1 h, at 190 °C for 1 h, and at 200 °C to No more water was distilled out to obtain a polyetherester oligomer; then 0.06g of dibutyltin oxide was added to the polyetherester oligomer, and the reaction was carried out at 230°C for 1 h under high vacuum conditions (<50Pa) at 240°C. The following reaction was carried out for 3 h to obtain polyethylene furandicarboxylate-co-diglycol, whose performance parameters are shown in Table 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap