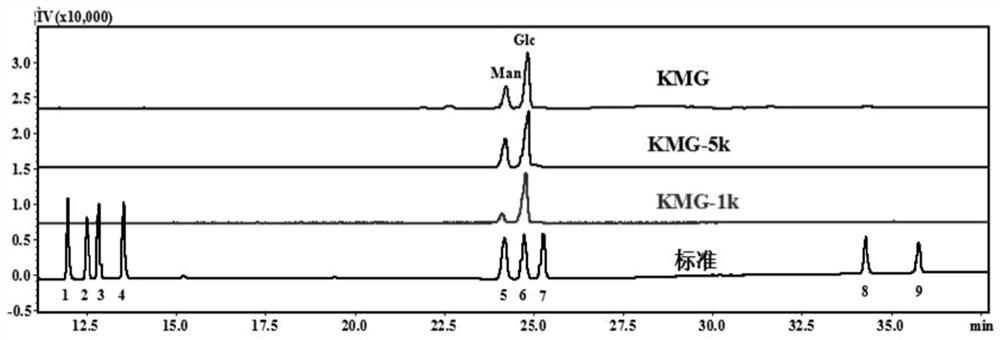

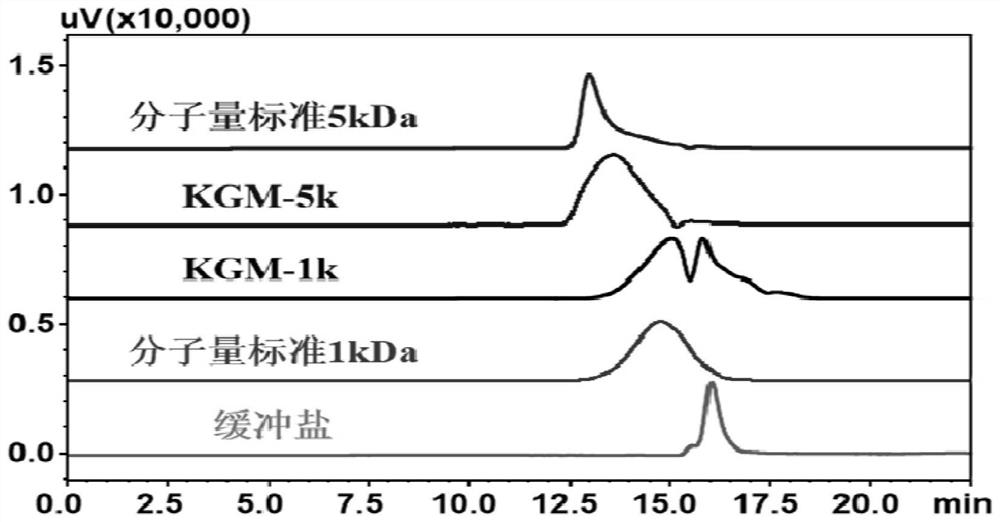

Application of konjac polysaccharide degradation products kgm-1k and kgm-5k in the preparation of probiotic protective agent

A konjac polysaccharide and degradation product technology is applied in the biological field to achieve the effects of enhanced stress resistance, improved survival rate and improved biological efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

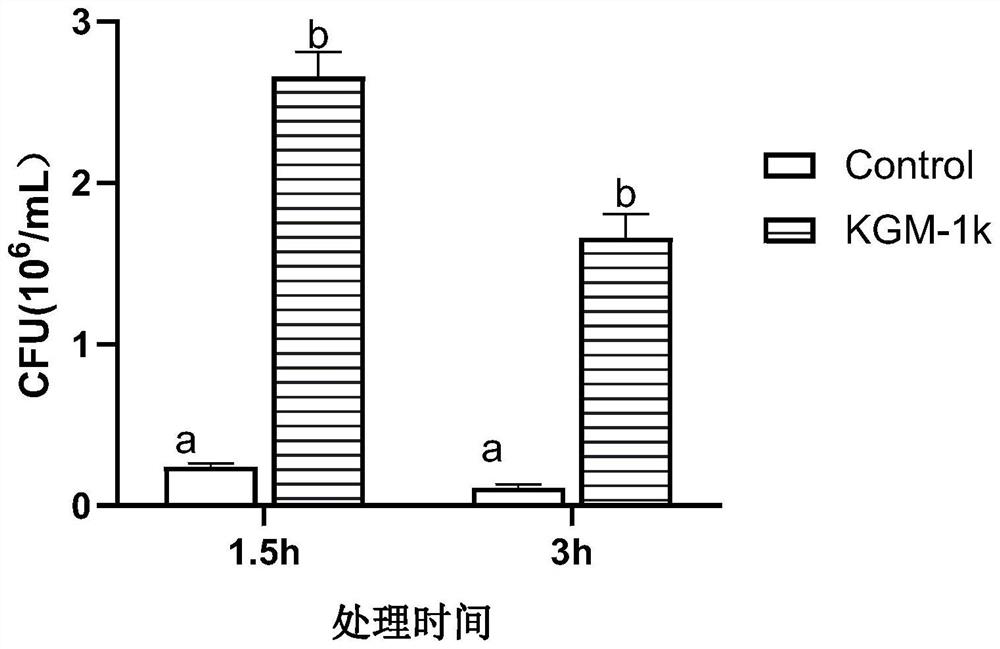

[0054] This example studies the effect of konjac polysaccharide degradation product KGM-1k on the survival of Bifidobacterium longum SQ011.

[0055] Preparation of simulated gastric juice containing KGM-1k, a degradation product of konjac polysaccharide: first prepare MRS medium without carbon source, adjust the pH of the MRS medium without carbon source to 2 with hydrochloric acid, add 5% (KGM- 1k / MRS medium, m / m) KGM-1k, a degradation product of konjac polysaccharide, was fully dissolved and then autoclaved at 121°C. Then, pepsin was dissolved in an appropriate amount of PBS solution (phosphate buffered solution) and sterilized by filtration; finally, the treated pepsin was added at a concentration of 3 g / L to the above-mentioned MRS medium containing KGM-1k, a degradation product of konjac polysaccharide. .

[0056] Preparation of simulated small intestinal fluid containing KGM-1k, a degradation product of konjac polysaccharide: first, the pH of the MRS medium without carb...

Embodiment 2

[0071] This example studies the effect of konjac polysaccharide degradation product KGM-5k on the survival of Bifidobacterium longum SQ011.

[0072] Preparation of simulated gastric juice containing KGM-5k, a degradation product of konjac polysaccharide: first prepare MRS medium without carbon source, adjust the pH of the medium to 2 with hydrochloric acid, add 5% (KGM-5k / MRS medium after packaging) , m / m) of konjac polysaccharide degradation product KGM-5k, fully dissolved and then autoclaved at 121 °C. Pepsin was then dissolved in an appropriate amount of PBS solution and filter sterilized. Finally, the treated pepsin was added to the above-mentioned MRS medium containing KGM-5k, a degradation product of konjac polysaccharide, at a concentration of 3 g / L.

[0073] Preparation of simulated small intestinal fluid containing KGM-5k, a degradation product of konjac polysaccharide: first, the pH of the MRS medium without carbon source was adjusted to 7 with sodium hydroxide, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com