Textile machine capable of preventing warp tension from being too tight

A textile machine and tension technology, applied in textiles, looms, textiles and papermaking, etc., can solve the problems of increasing the production cost of textile products, reducing the service life of textile machines, and the failure of textile machines to work normally, so as to ensure that they cannot work normally, The effect of improving the service life and avoiding repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

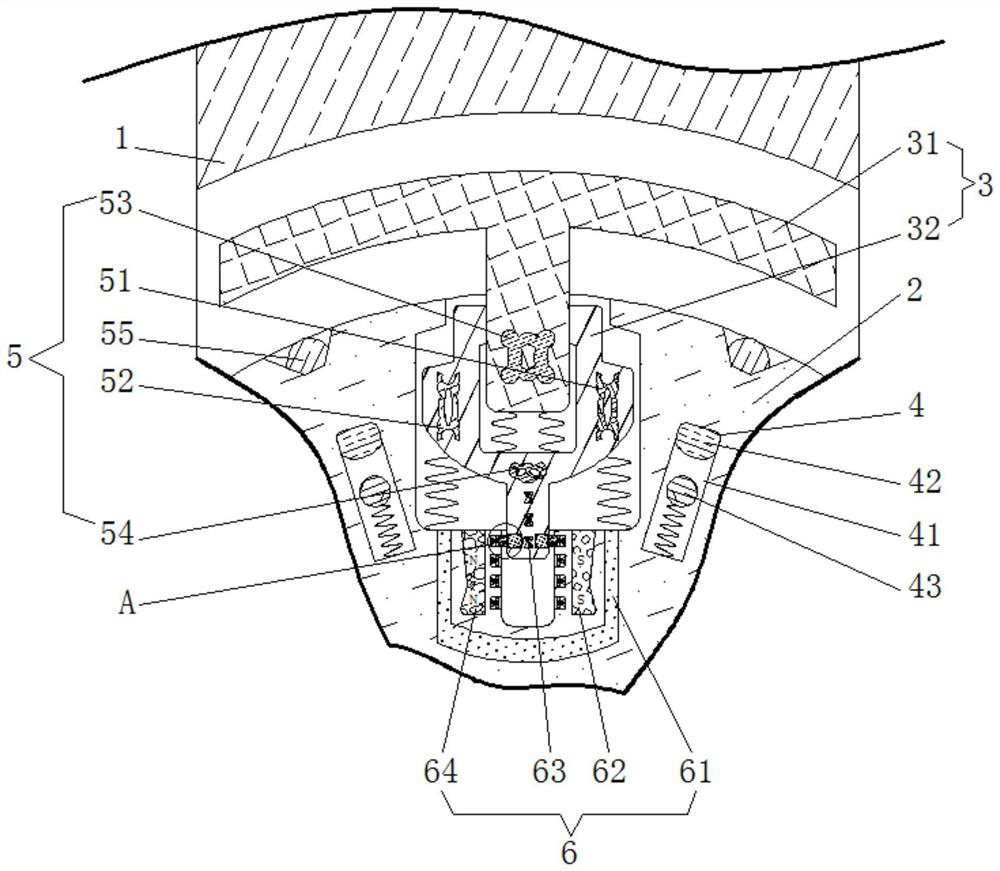

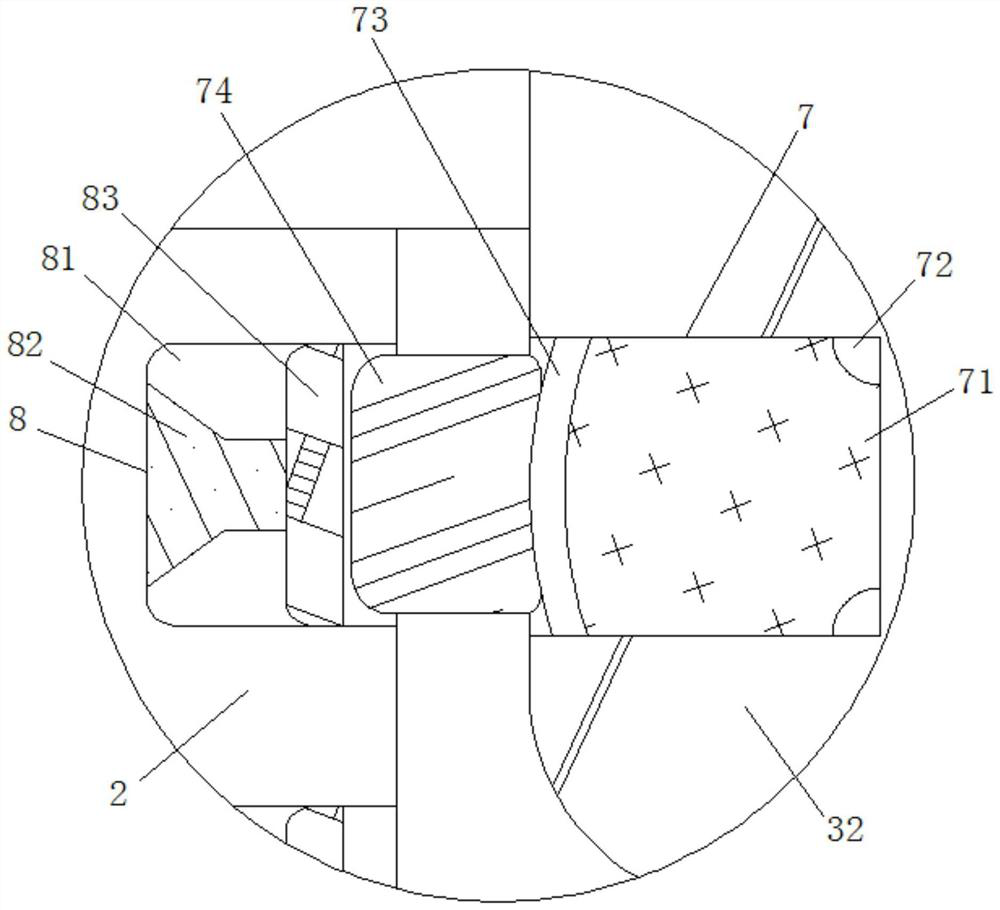

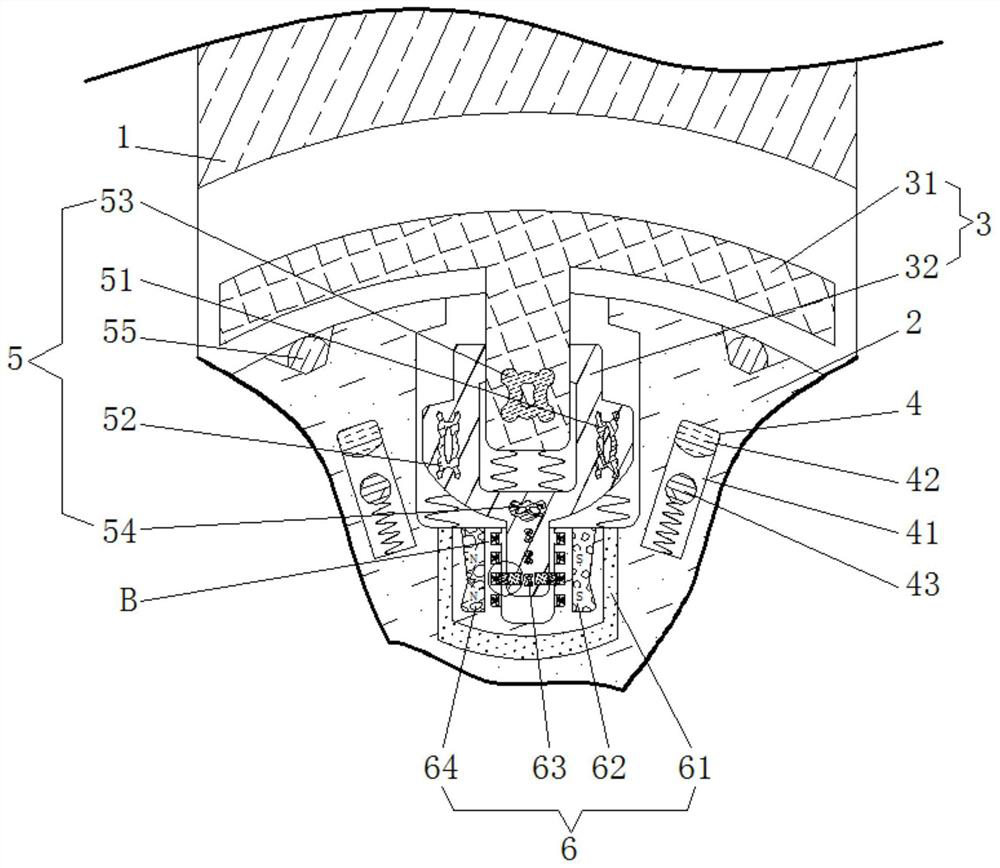

[0024] see Figure 1-4 , a textile machine for preventing excessive warp tension, comprising a housing 1, a roller shaft 2, a force receiving mechanism 3, an energizing mechanism 4, a trigger mechanism 5, a transmission mechanism 6, a limit mechanism 7 and a control mechanism 8, the housing 1 The inner wall of the roller shaft 2 is movably connected with a roller shaft 2, and the inner wall of the roller shaft 2 is elastically connected with a force bearing mechanism 3. The force bearing mechanism 3 includes a force bearing plate 31 and a slide bar 32. The inner wall of the roller shaft 2 is elastically connected with a slide bar 32, and the slide bar The inner wall of 32 is elastically connected with a force plate 31, the force plate 31 is attached to the inner wall of the slide bar 32, the force mechanism 3 is used to push the movement of the trigger mechanism 5, and the inner wall of the roller shaft 2 is movably connected with an energization mechanism 4. The mechanism 4 i...

Embodiment 2

[0027] see Figure 1-4 , a textile machine for preventing excessive warp tension, comprising a housing 1, a roller shaft 2, a force receiving mechanism 3, an energizing mechanism 4, a trigger mechanism 5, a transmission mechanism 6, a limit mechanism 7 and a control mechanism 8, the housing 1 The inner wall of the roller shaft 2 is movably connected with a roller shaft 2, and the inner wall of the roller shaft 2 is elastically connected with a force bearing mechanism 3. The force bearing mechanism 3 includes a force bearing plate 31 and a slide bar 32. The inner wall of the roller shaft 2 is elastically connected with a slide bar 32, and the slide bar The inner wall of 32 is elastically connected with a force plate 31, the force plate 31 is attached to the inner wall of the slide bar 32, the force mechanism 3 is used to push the movement of the trigger mechanism 5, and the inner wall of the roller shaft 2 is movably connected with an energization mechanism 4. The mechanism 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com