A method for recovering cave ore in the process of changing from caving method to filling method

A recovery method and caving technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of prolonging the service life of mines, achieve significant safety effects, eliminate safety hazards, and reduce resource losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

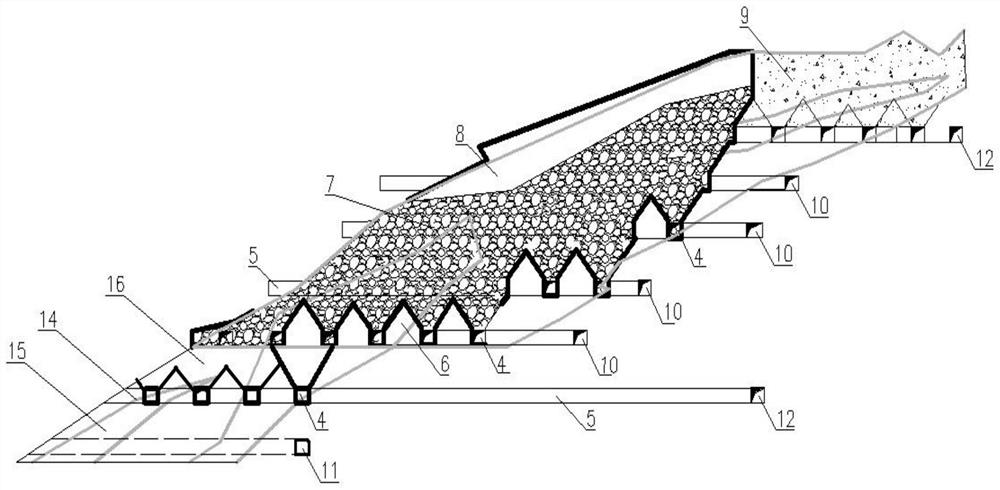

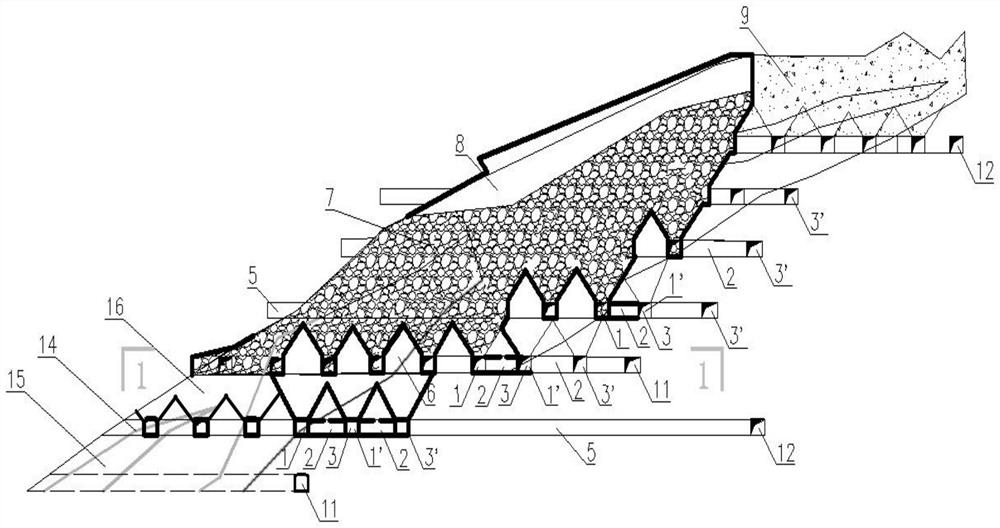

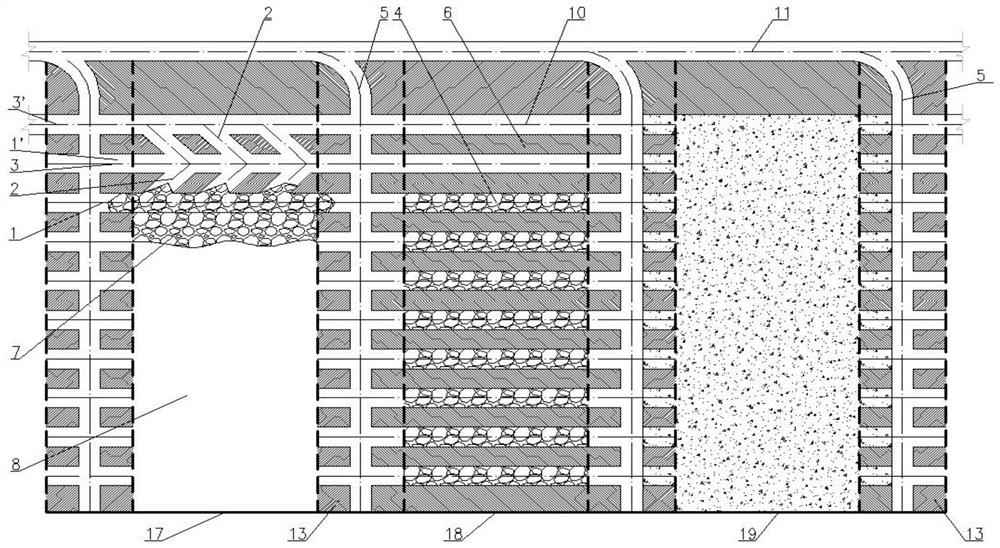

[0022] In order to better describe the present invention, a method for recovering the ore deposit in the process of converting the caving method to the filling method of the present invention will be further described in detail below with reference to the accompanying drawings.

[0023] Depend on figure 2 The present invention as shown is a cross-sectional view of the storage hole ore recovery project layout and combined with figure 2 , figure 1 It can be seen that, in the process of converting the caving method to the filling method of the present invention, the recovery method of the deposit hole ore, the original subsection along the vein transport road 10, the stage along the vein transport road 12 and the original mine approach 4 belong to the original project, and the storage When designing the mining of the Long Mine, the original project should be used as much as possible to reduce the amount of engineering. Specifically, the following processes are used to recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com