Middle-waisted bidirectional filling and mining method under canopy guard in thick and great metal mine in sea bed

A backfill mining method, a technology for metal mines, applied in the fields of backfill, mining equipment, mining minerals, etc., can solve the problems of low production efficiency, low degree of mechanization, and resource loss and waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

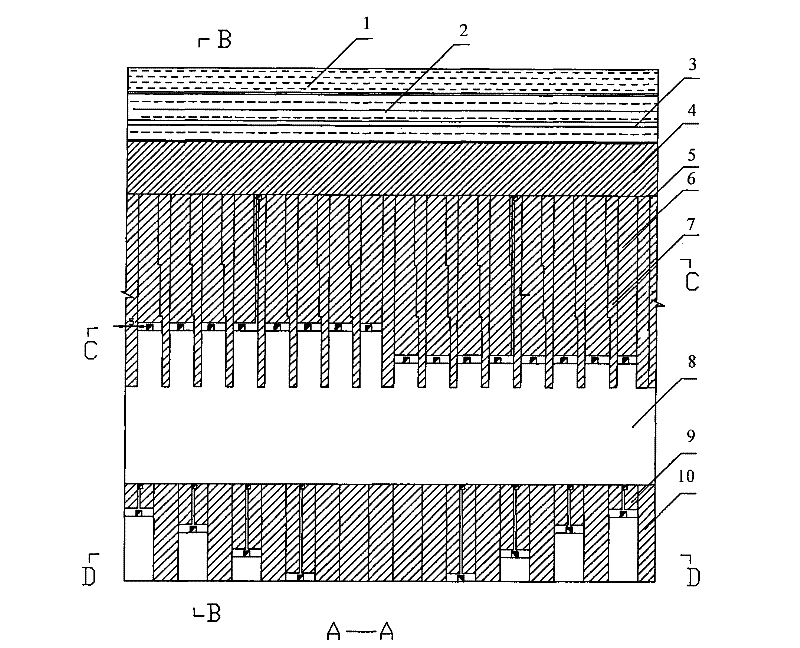

[0035] The Xinli mining area of Sanshandao Gold Mine is my country's first hard rock mine engaged in underground mining of continental shelf coastal deposits. Most of the ore bodies currently mined are located below seawater. The No. 1 ore body is the main ore body in the deposit. The overall trend of the ore body is 62°, dipping to the southeast, and the dip angle is 33-67°, with an average of 46°. The dip angle tends to become steeper from north to south. The ore body is 20-30m thick. The single engineering grade of the ore body is 1.52-12.53g / t, with an average of 3.26g / t. The seabed deposit in the Xinli mining area of the Sanshandao Gold Mine adopts the mid-waist two-way filling mining method.

[0036] (1) specific implementation plan

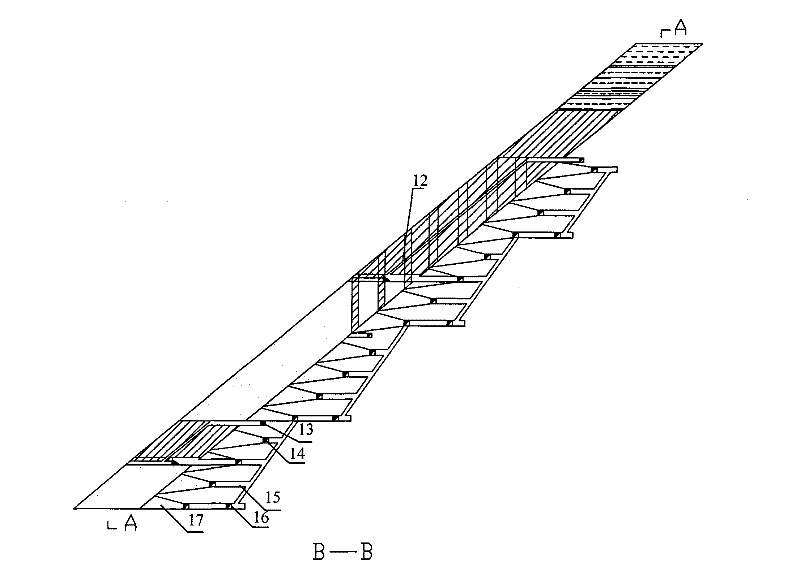

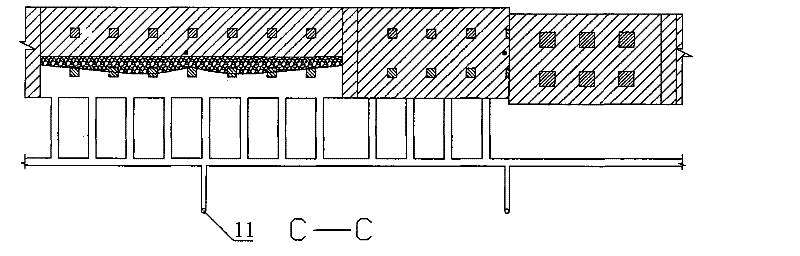

[0037] ① in figure 1 Among them, there is 30-50m of sea mud under 10m deep seawater, and there is a water-resisting layer with a thickness of 1-2m in the sea mud sediment. ~30m. In order to ensure safe, scientific, economical, high-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com