A method for calibrating a cross-shaped caliper for bogie frame inspection

A calibration method, cross-shaped technology, applied in the direction of measuring gauges, measuring devices, mechanical measuring devices, etc., can solve the problems of no calibration standards and methods, no calibration devices, and the inability to carry out calibration work, etc., to achieve simple structure and convenient use , the effect of meeting the calibration requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

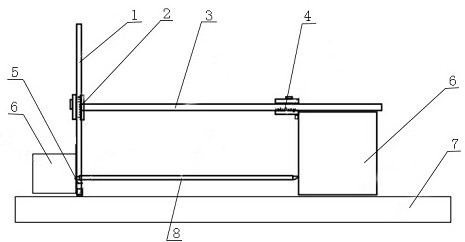

[0028] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

[0029] A cross-shaped caliper calibration method for bogie frame detection is as follows:

[0030] Step 1. Determine the calibration conditions: the measuring tool should be calibrated indoors at a temperature of 20±5℃, and the time for the measured measuring tool and the main calibration tool to balance the temperature on the indoor plate 7 is not less than 2h;

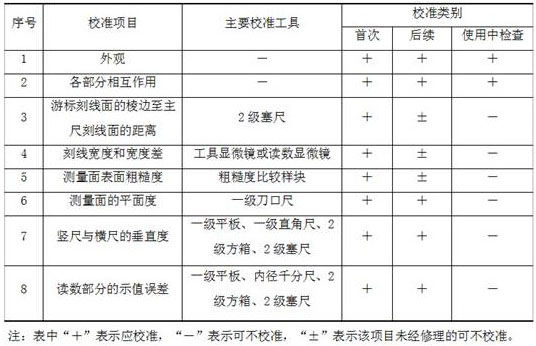

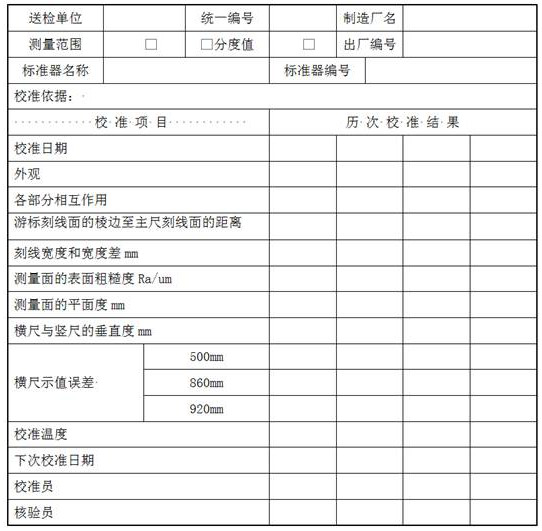

[0031] Step 2. Check whether the main calibration standard device meets the requirements. The main calibration standard devices include: Grade 2 feeler gauge, tool microscope or reading microscope, roughness comparison sample block, Grade 1 knife edge ruler, Grade 1 flat plate, Grade 1 right angle, Class 2 square box and inner micrometer; see Table 1 for calibration items and main calibration standards:

[0032] Table 1 Calibration items and main calibration standard table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com