Crop cultivation planting frame

A technology for planting racks and crops, applied in the field of crops, can solve problems such as low growth efficiency, damage to branches and leaves, and inability to ensure the spacing between planting plants, so as to achieve the effect of improving light stability and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

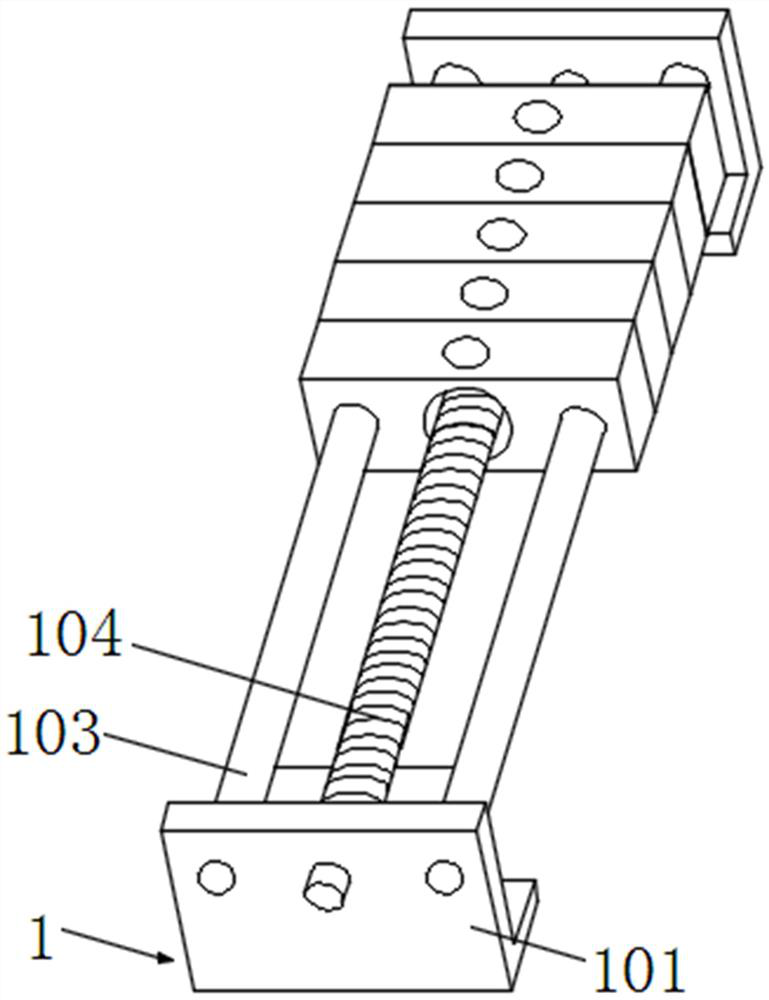

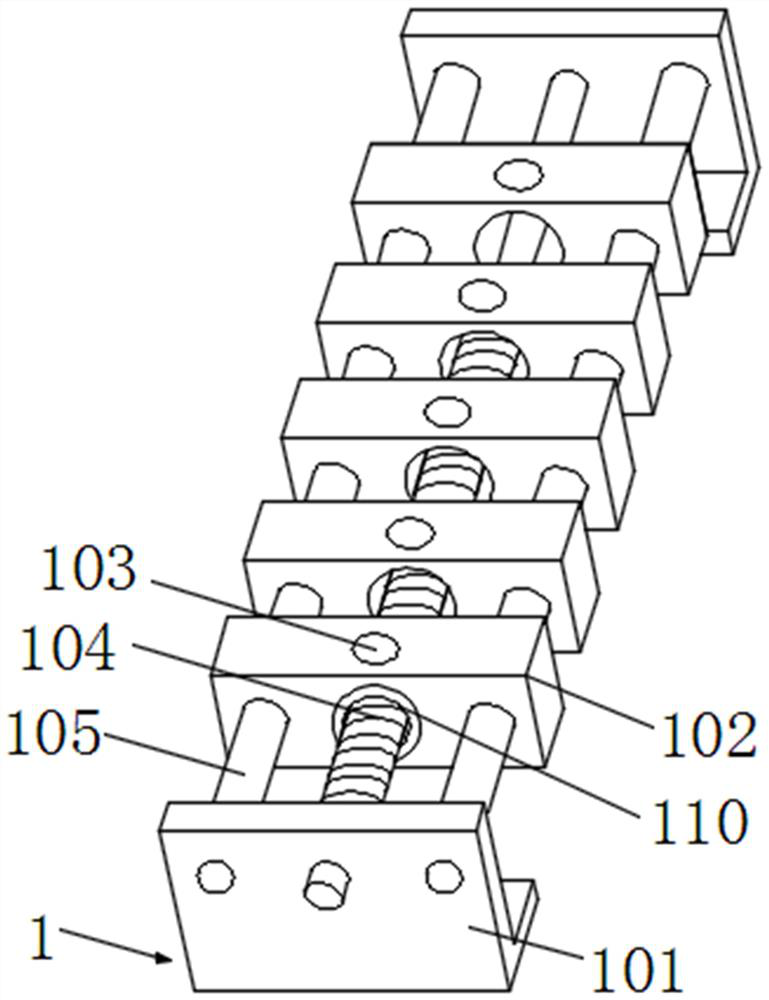

[0028] Such as Figure 1-4As shown, a planting frame for crop cultivation includes a frame body (2), and three sets of spacing moving structures (1) are arranged in the middle of the frame body (2), and the spacing moving structures (1) pass through the light moving structures provided on both sides (3) Connected with the frame body (2), the distance moving structure (1) includes a fixed plate (101), and two sets of sliding rods (105) and threaded rods (104) are arranged between the fixed plates (101), and the threaded rods (104) is located between the sliding rods (105), the threaded rods (104) and the outside of the sliding rods (105) are interspersed with several groups of spacing moving plates (102), and the spacing moving plates (102) are fixed with fixing holes (103 ), there is a threaded fixing block (110) in the middle of the first spacing moving plate (102), the threaded rod (104) penetrates the inside of the threading fixing block (110), the thread drives the rotatio...

Embodiment 2

[0033] Such as Figure 1-7 As shown, a planting frame for crop cultivation includes a frame body (2), and three sets of spacing moving structures (1) are arranged in the middle of the frame body (2), and the spacing moving structures (1) pass through the light moving structures provided on both sides (3) Connect with the frame body (2).

[0034] The light moving structure (3) includes a mobile frame (301) and a frame fixing frame (303) fixed at one end of the frame body (2). One end of the frame fixing frame (303) is provided with a threaded bar (304), and the threaded bar (304) The threaded connection is provided with a threaded stopper (305), the upper end of the threaded stopper (305) is slidably connected with the frame groove (302) provided on the moving frame (301), and the inner side of the threaded stopper (305) is connected to the frame One end of the fixed frame (303) is fixedly connected, the round shaft (306) provided at one end of the threaded bar (304) is fixed ...

Embodiment 3

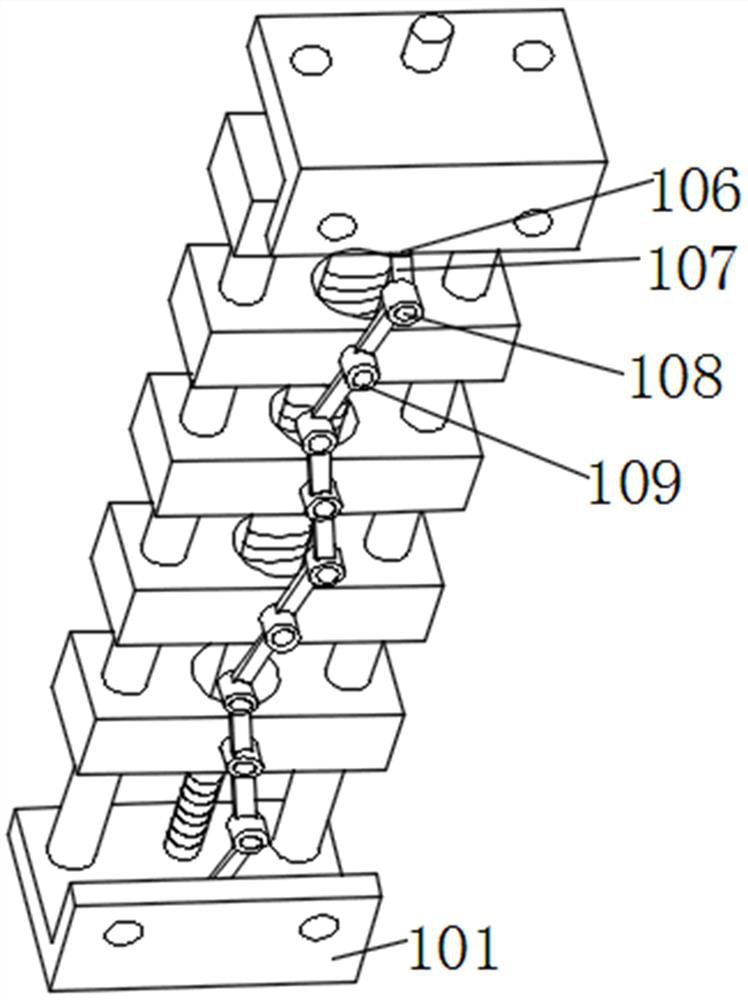

[0038] Such as Figure 1-7 As shown, a planting frame for crop cultivation includes a frame body (2), and a closing structure (4) is arranged on the upper end and one side of the frame body (2). The closing structure (4) includes a telescopic structure (401), and the telescopic structure The telescopic rod (402) of (401) stretches out, and drives the No. 2 linkage rod (406) fixed to the telescopic rod (402) to move forward, and one end of the No. 2 linkage rod (406) is movably connected to a No. 1 linkage rod (405 ), one end of the No. 1 linkage rod (405) is fixedly connected to the No. 1 folding plate (404), and then the No. 1 linkage rod (405) exerts pressure on the No. 1 folding plate (404), pushing the No. 1 folding plate (404) Shrink inward, and then the pulley at the front end of the No. 2 folding plate (403) slides along the track on one side of the frame body (2) to the other end, and then closes the front end of the frame body (2).

[0039] The uppermost end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com