Shoe washing machine

A shoe washing machine and shoe washing technology, applied in the field of shoe washing machines, can solve the problems of damp, affecting the service life, stability and reliability cannot be guaranteed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

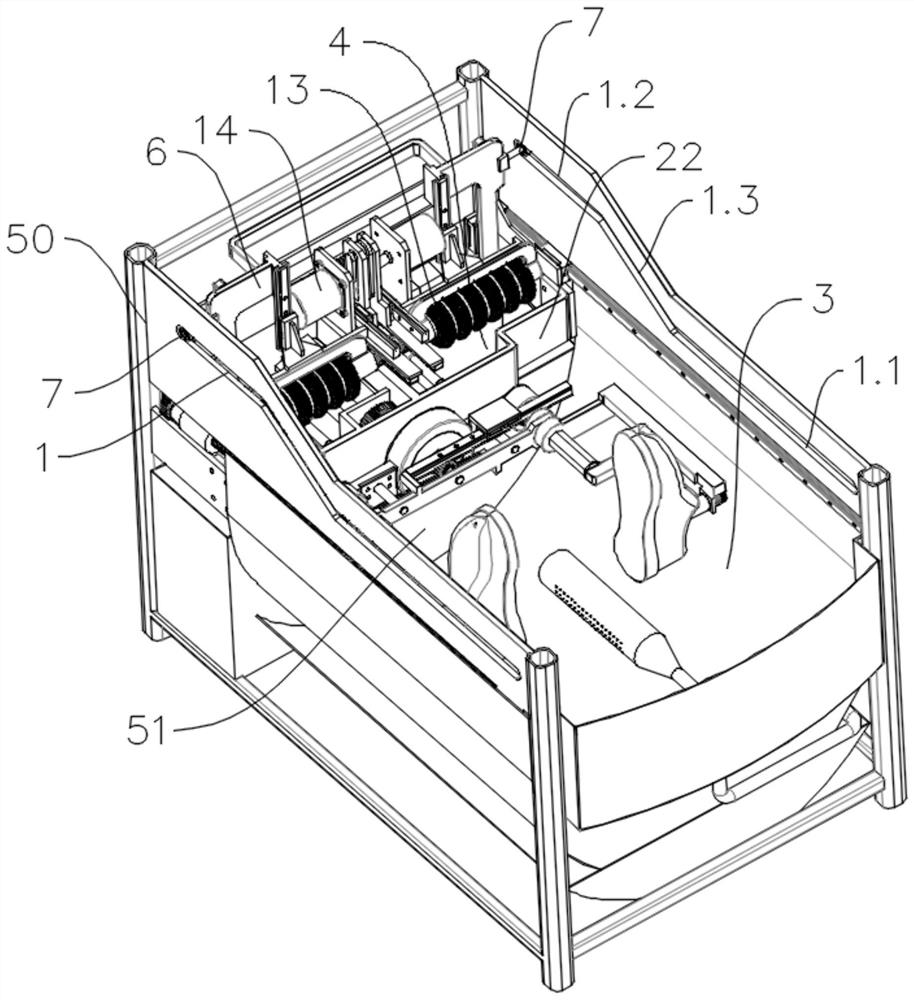

[0044] like Figure 1-Figure 8 As shown, the present embodiment provides a shoe washing machine, including a horizontal shoe washing box, a walking track 1, a shoe brush assembly, a walking drive mechanism for driving the shoe brush assembly to move along the walking track 1, and a horizontal shoe washing box There is an equipment rack 50 inside, and the walking track 1 is set on the equipment rack 50;

[0045] The walking track 1 is followed by the first track 1.1 and the second track 1.2 along its extending direction. The area corresponding to the first track 1.1 in the horizontal shoe washing box is the shoe washing area 3, and the horizontal shoe washing box is connected to the second track 1. 1.2 The corresponding area is the installation area 4, and a partition 51 is provided between the shoe washing area 3 and the installation area 4; when the shoe brush assembly moves to the first track 1.1, the shoe brush assembly is located in the shoe washing area 3, and the shoe br...

Embodiment 2

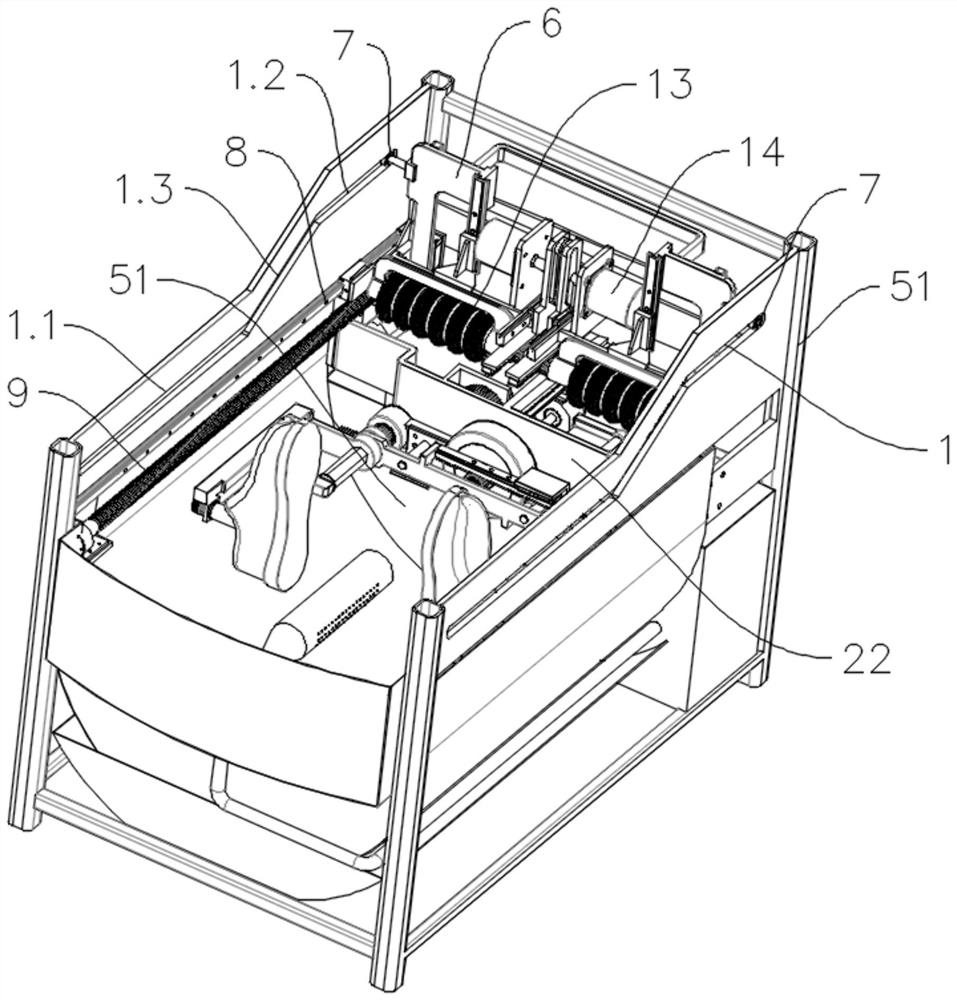

[0051] This embodiment is optimized on the basis of the above-mentioned embodiment 1.

[0052] Considering that in order to facilitate the installation of other mechanisms for driving the rotation angle of shoes in the installation area 4, to make room for the design of this part of the mechanism, the walking track 1 is followed by the first track 1.1, the transition track 1.3 and the second track along its extending direction. Two tracks 1.2, there is a height difference between the first track 1.1 and the second track 1.2, preferably, the first track 1.1 is selected to be lower than the second track 1.2, and the shoe brush assembly includes a mobile bracket 5 and a vertical sliding fit with the mobile bracket 5 The rolling brush work mobile support 6, the rolling brush work mobile support 6 is equipped with a rolling brush assembly, and the rolling brush work mobile support 6 is slidably matched with the walking track 1.

[0053]This kind of design, in the process of driving...

Embodiment 3

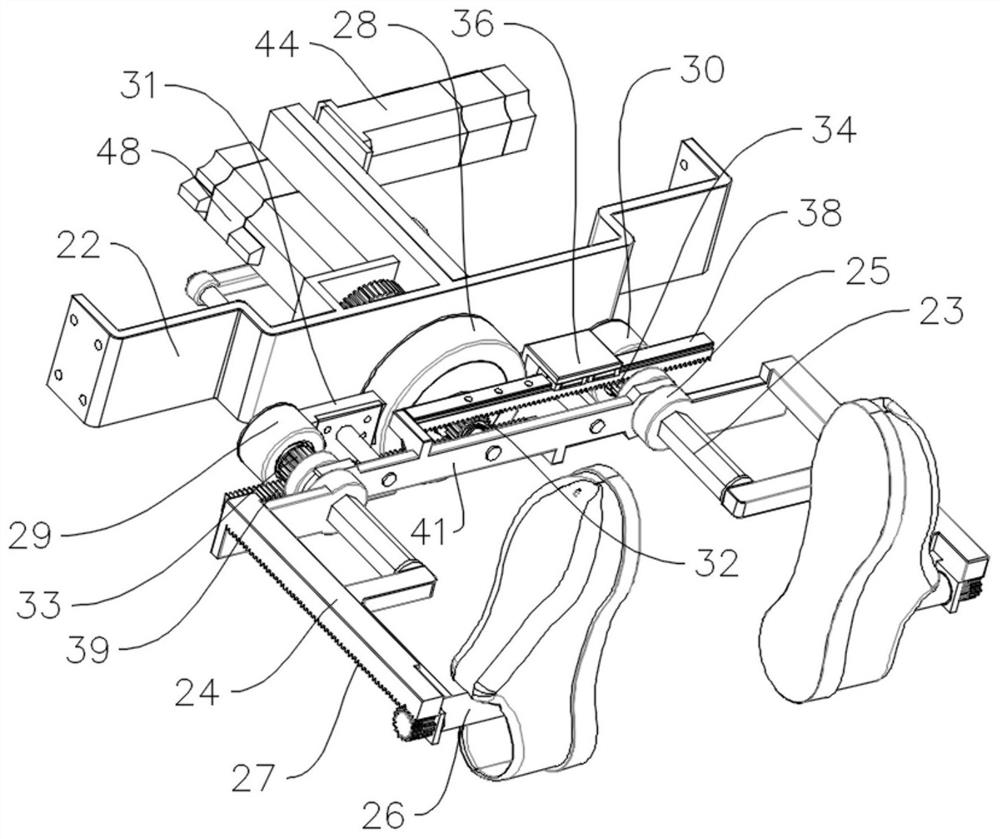

[0055] This embodiment is optimized on the basis of the above-mentioned embodiment 2.

[0056] The vertical sliding fit between the rolling brush assembly and the rolling brush working mobile support 6.

[0057] Currently, the moving device drives the roller brush to walk in a straight line, but the shoe has a curved shape. Therefore, the roller brush cannot effectively match the shape of the shoe during the straight-line walking process, and the scrubbing effect is not good. The vertical sliding fit between the rolling brush assembly and the rolling brush work moving support 6, then in the process that the rolling brush assembly moves along with the rolling brush work moving support 6, the rolling brush assembly can also move up and down along with the shape of the shoes, which can be more A good realization matches the shape of the shoe and the scrubbing effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com