Palladium-copper catalyst and its preparation method and application

A catalyst, palladium-copper technology, applied in the field of palladium-copper catalyst and its preparation, can solve the problems of complex preparation methods and insufficient catalytic activity, and achieve the effects of simple steps, good industrial application prospects, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The embodiment of the present application provides a palladium-copper catalyst and a preparation method thereof. The preparation method of the palladium-copper catalyst comprises the following steps:

[0034] Preparation of palladium nanoparticles: dissolving palladium acetate in absolute ethanol, and constant temperature treatment at 0-20°C for 24-48 hours to obtain an absolute ethanol solution containing palladium nanoparticles;

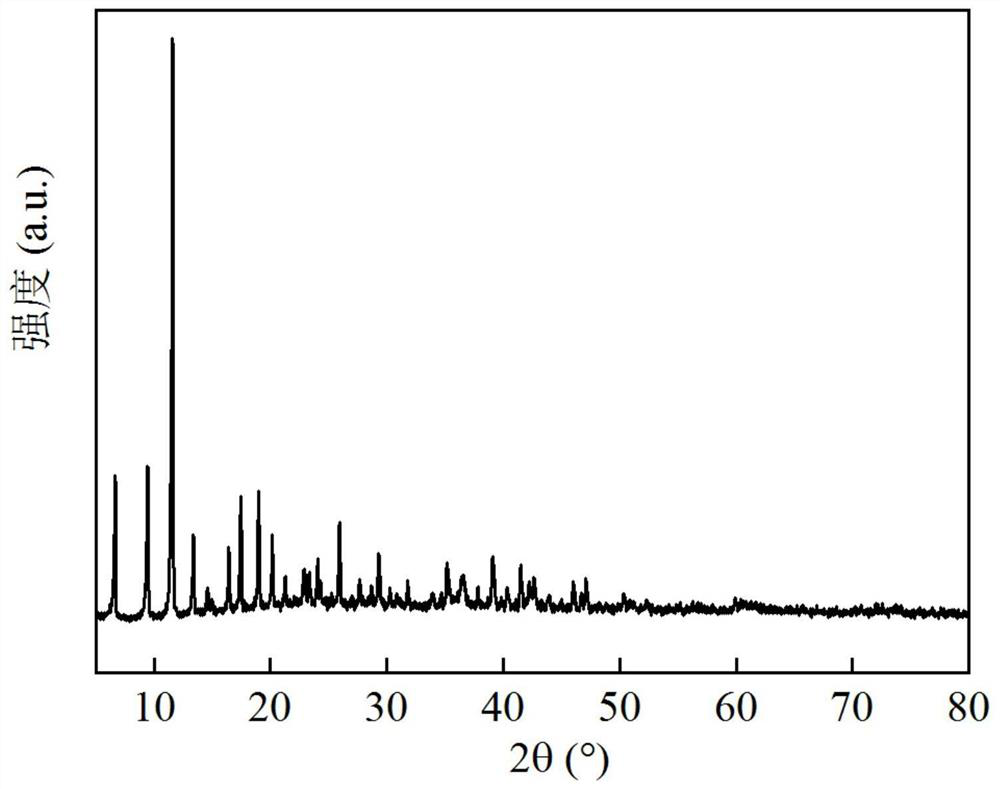

[0035] Preparation of palladium-modified copper-based metal-organic framework: dissolving trimesic acid in the absolute ethanol solution containing palladium nanoparticles, adding copper nitrate aqueous solution, mixing evenly, and performing solvothermal reaction to obtain palladium-modified copper-based metal organic framework;

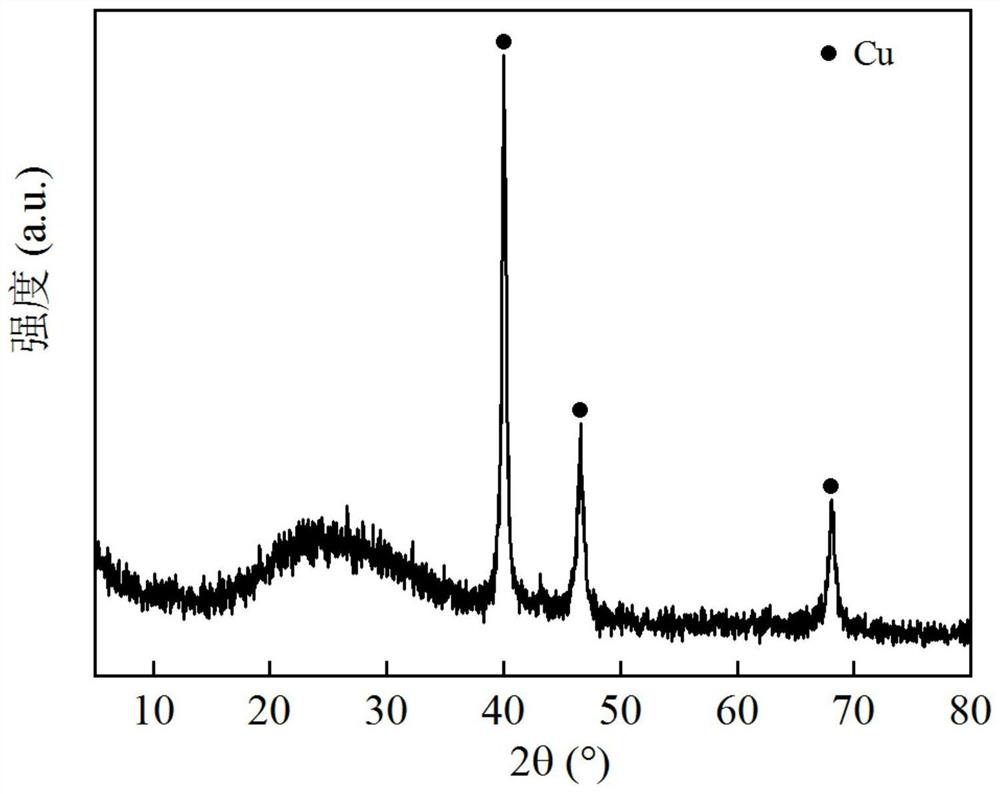

[0036] Calcination: Calcining the palladium-modified copper-based metal-organic framework in an inert gas atmosphere to obtain the palladium-copper catalyst supported by porous carbon.

[0037] The preparation me...

Embodiment 1

[0067] The present embodiment provides a kind of palladium-copper catalyst, and the preparation method of this palladium-copper catalyst comprises the following steps:

[0068] Preparation of palladium nanoparticles: dissolving 0.0085 mmol of palladium acetate in 10 mL of absolute ethanol, ultrasonic treatment at 0°C for 10 minutes, and then constant temperature treatment at 0°C for 48 hours to obtain an absolute ethanol solution containing palladium nanoparticles;

[0069] Preparation of palladium-modified copper-based metal-organic framework: Dissolve 1 mmol of trimesic acid in the above-mentioned absolute ethanol solution containing palladium nanoparticles, and sonicate at room temperature for 10 minutes; then weigh 1.7 mmol of copper nitrate trihydrate and dissolve it in 10 mL to remove A copper nitrate aqueous solution is formed in ionized water, and the copper nitrate aqueous solution is added to an anhydrous ethanol solution containing trimesic acid-containing palladium ...

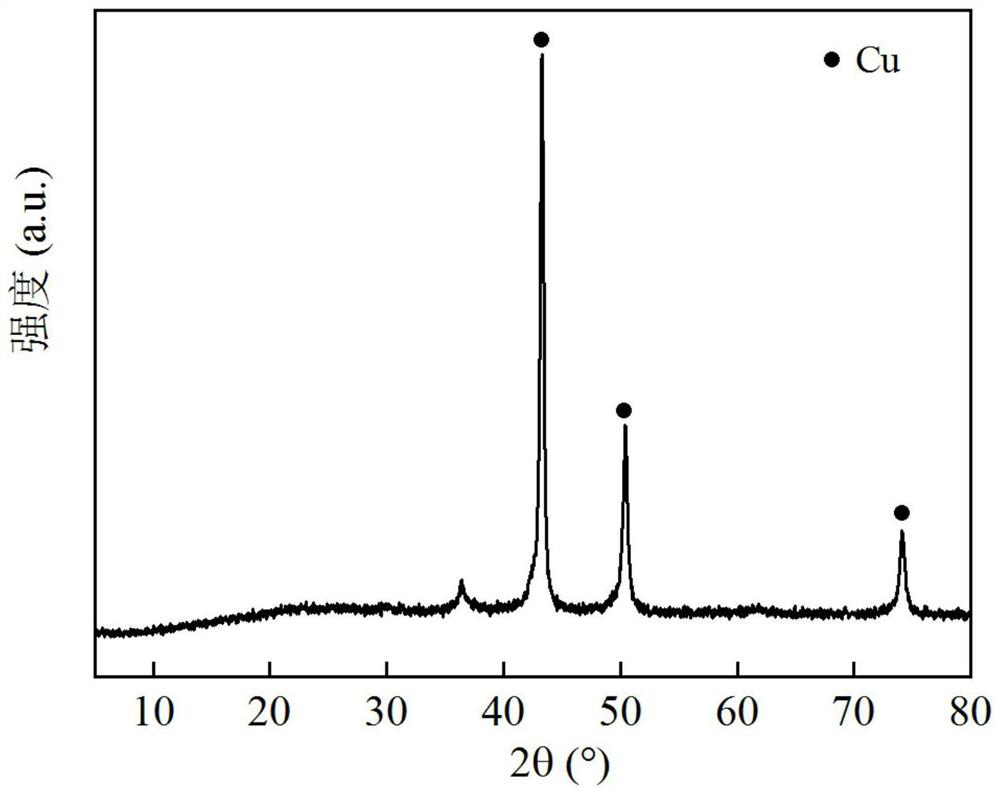

Embodiment 2

[0073] The difference between this example and Example 1 is that in the step of preparing palladium nanoparticles, 0.017 mol of palladium acetate was weighed and dissolved in 10 mL of absolute ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com