Non-planar EFI printing device and method based on space-adjustable array nozzles

A non-planar, nozzle technology, applied in printing devices, printing and other directions, can solve the problems of expensive equipment, complex process, poor uniformity of non-planar structure, etc., and achieve the effect of low cost, simple process and short cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

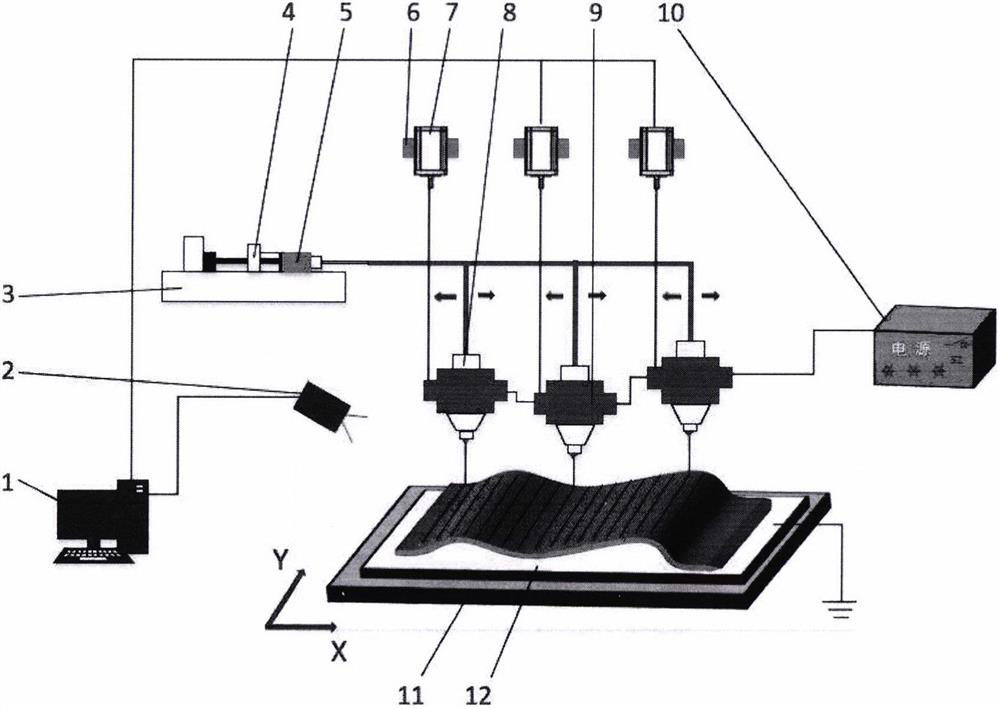

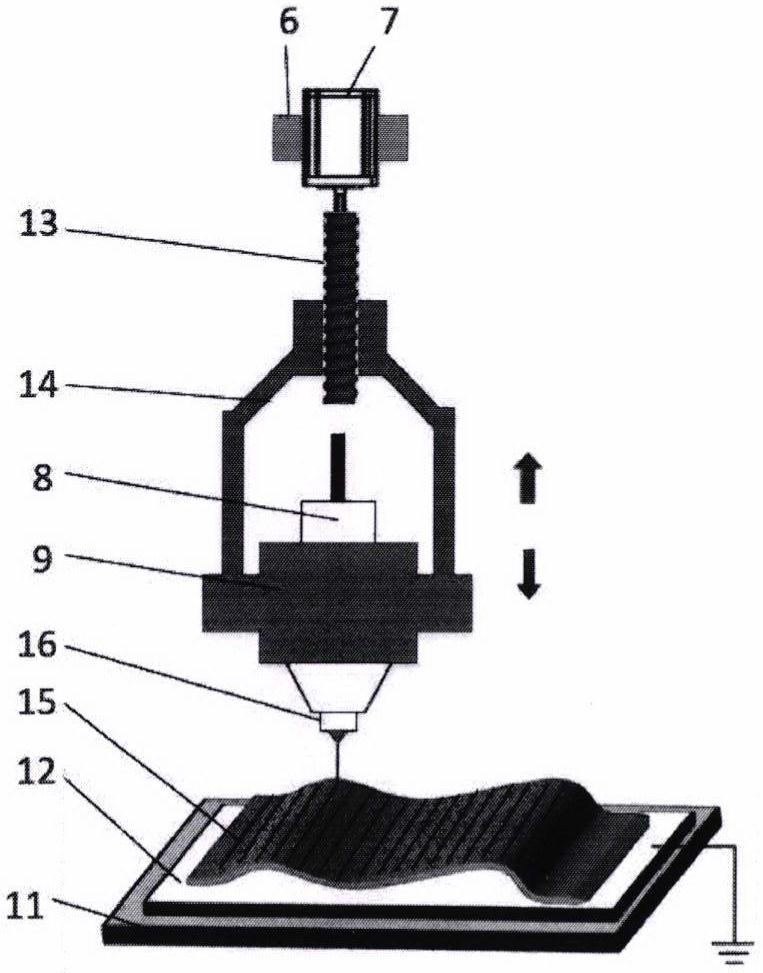

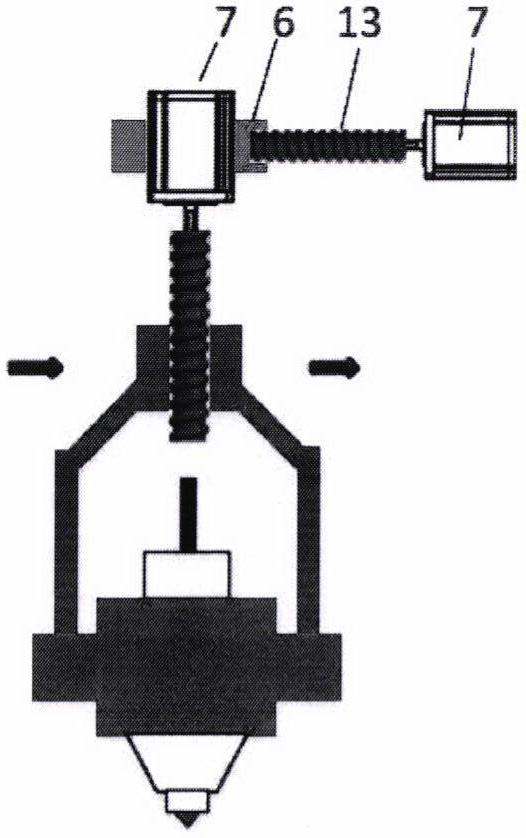

[0020] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings. see Figure 1 to Figure 3 .

[0021] This embodiment discloses a non-planar electrospray printing device based on an array nozzle with adjustable space. The device mainly includes four parts: a fluid jet printing module, a motion module, an image recognition module and a control module. First, use a high-definition CCD camera to identify the spatial morphology of the printing substrate, and adjust the distance between the array nozzle and the printing substrate online according to the identified information; then, use the functional ink to adjust the electric field force, gravity, solution surface tension / dielectric force Under the comprehensive action of viscous force, etc., the fine jet flow is obtained, and the substrate is heated by external conditions, so that the functional ink printed on the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com