Novel adjustable substrate delivery roll device

A technology of conveying rollers and base adjustment, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of affecting straightness, insufficient assembly precision machining accuracy, high noise, etc., to ensure rigidity and reliability. performance, reduce equipment manufacturing costs, and ensure the effect of adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

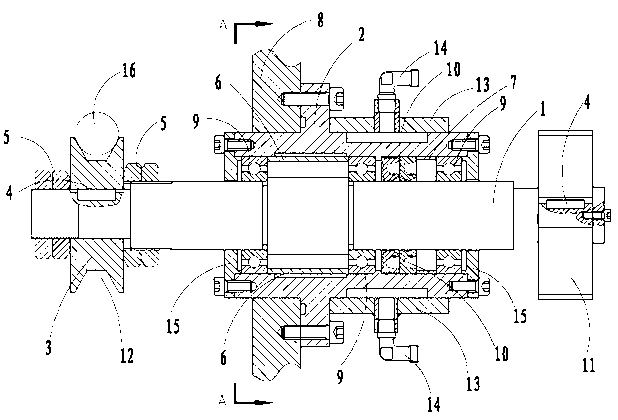

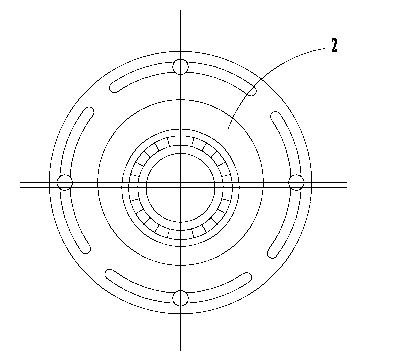

[0016] As in the accompanying drawings figure 1 As shown, the present invention is provided with a stepped shaft 1, and the outer periphery of the stepped shaft 1 is provided with a bearing seat 2, and the stepped shaft 1 is fixed on the vacuum chamber wall 8 through the bearing seat 2, and the bearing seat 2 is an eccentric structure, That is to separate the centerline of the mounting hole of the bearing housing 2 from the centerline of the outer circle installed in the wall, as shown in the attached drawings figure 2 As shown, the center line of the mounting hole of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com