Pre-charging control system for lithium battery assembly of industrial vehicle

A technology for industrial vehicles and control systems, applied in the field of lithium battery assembly pre-charge control systems for industrial vehicles, can solve problems such as damage to circuit components and failure of drive motor controllers to avoid energy shocks and ensure power supply security. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

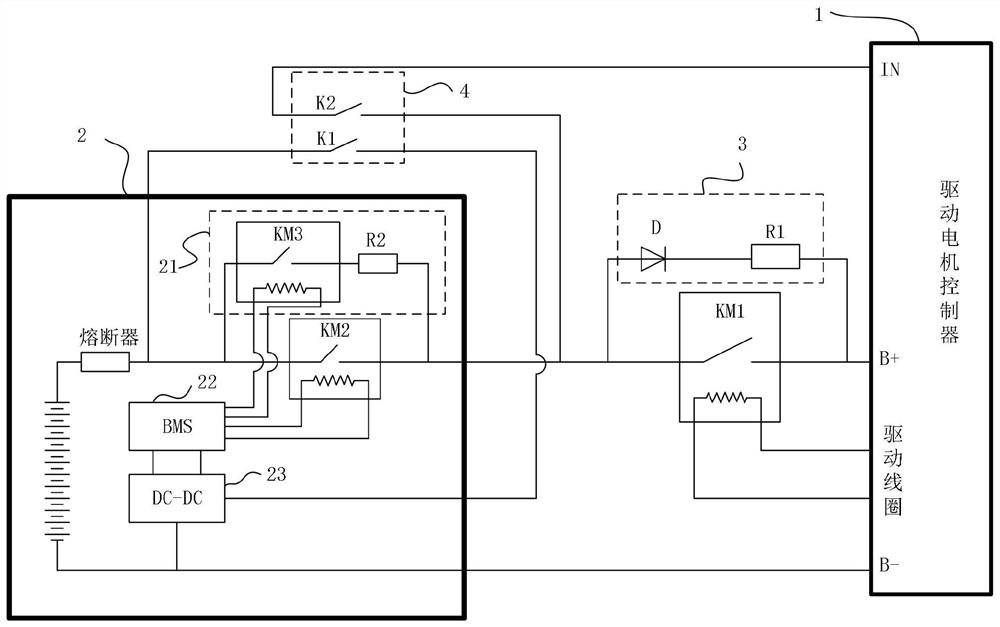

[0022] The drive motor controller in equipment such as industrial vehicles generally uses a key switch to control whether the drive motor controller and the power supply are directly connected or not.

[0023] Considering that the moment the contactor connected between the drive motor controller and the power supply is turned on from disconnection, a large instantaneous current will be generated, which can be as high as 2000A, which is easy to damage the contactor or even impact the drive motor controller internal circuit devices. Therefore, the corresponding pre-charging circuit can be configured for the contactor. After the key switch is inserted, the pre-charging circuit first charges the two ends of the contactor. The contactor can only be closed when the voltage difference between the two ends is small, so as to avoid driving The moment when the controller and the power supply are connected, the circuit device will be damaged due to excessive current.

[0024] However, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com