Method for preparing tracing ceramsite and method for detecting fracturing crack width by utilizing tracing ceramsite

A tracking and ceramsite technology, applied in the directions of surveying, earthwork drilling, and fluid extraction, it can solve the problem of not effectively pressing open, etc., and achieve the effect of super capture ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

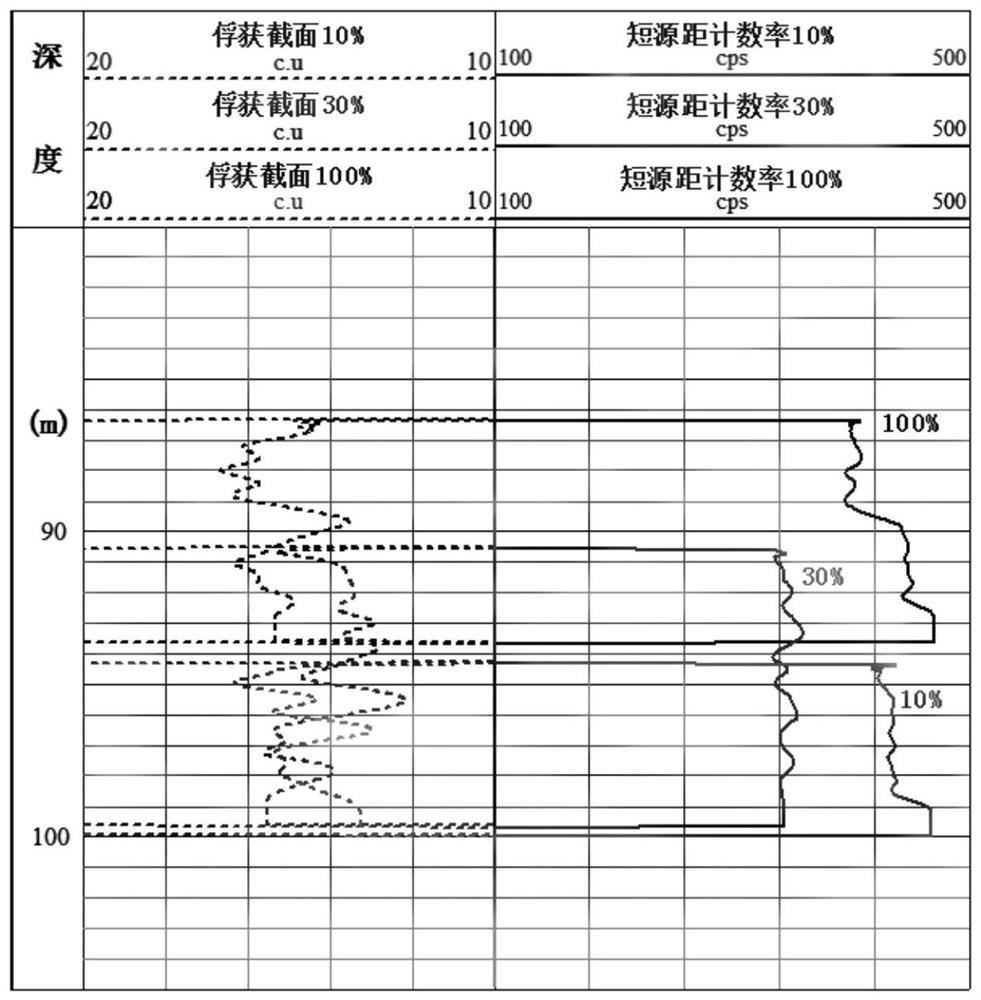

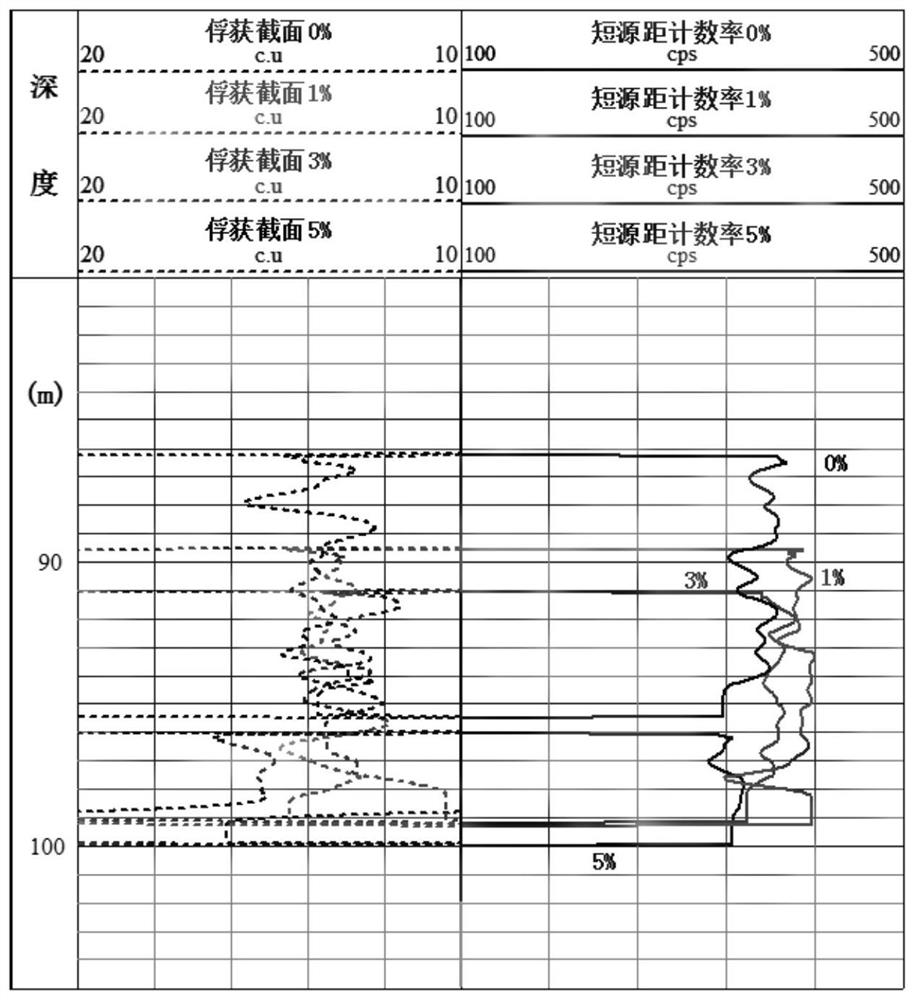

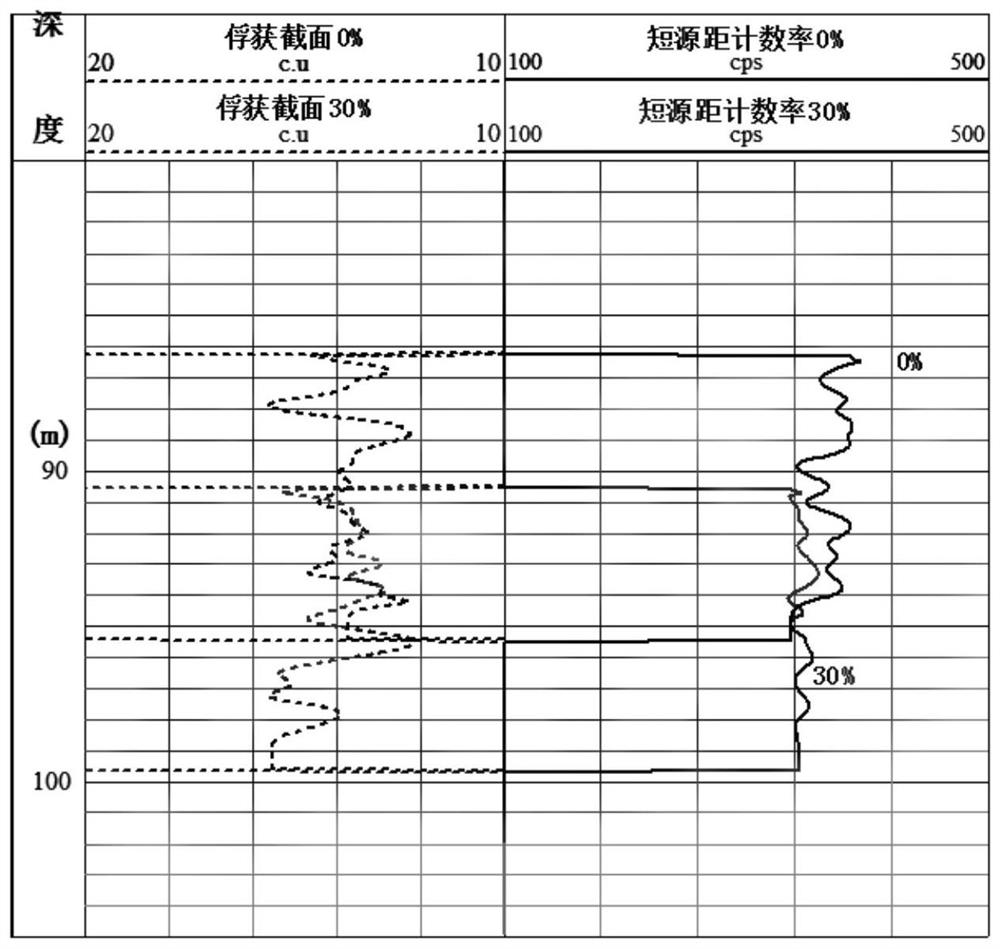

[0025] as attached figure 1 Shown, the present invention provides a kind of method for the preparation of tracer ceramsite, the method comprises the following steps:

[0026] Step 1: Send neutron capture material into a ball mill, the melting point of the neutron capture material is 1600°C, then add bauxite into the ball mill, and grind to obtain mixed mill powder;

[0027] Step 2: Send the mixed mill powder into the granulator for granulation, and sieve after the granulation is completed;

[0028] Step 3: After the screening is completed, it is sent to the rotary kiln for roasting at a roasting temperature of 1300 ° C. After roasting, it is cooled and the finished product is screened to obtain tracer ceramsite with excellent performance.

[0029] Specifically, using the obtained tracer ceramsite to detect the formation fracture width, the method includes the following steps:

[0030] Step A: injecting the prepared tracer ceramsite into the formation fracture to be detected;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com