Automatic transmission

A transmission and automatic transmission technology, which is applied in the field of automatic transmission and transmission devices, can solve the problems of impact, shifting impact, low transmission efficiency, etc., and achieve high production efficiency, solve the effects of deceleration and back pull, and stable and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

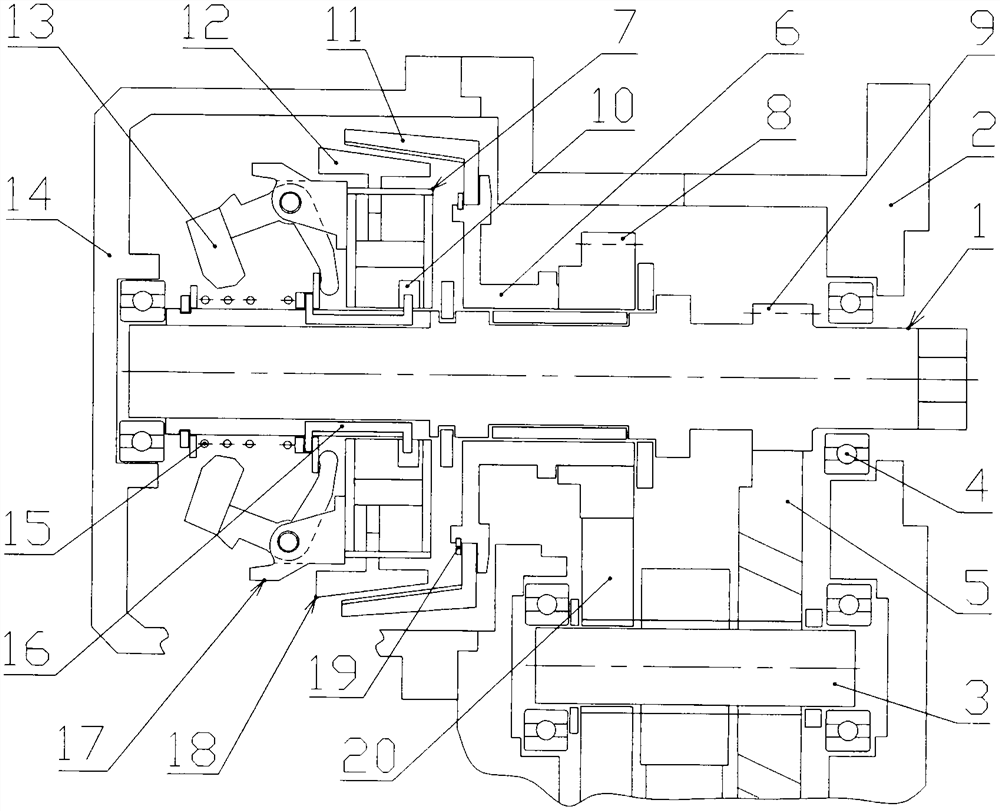

[0049] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

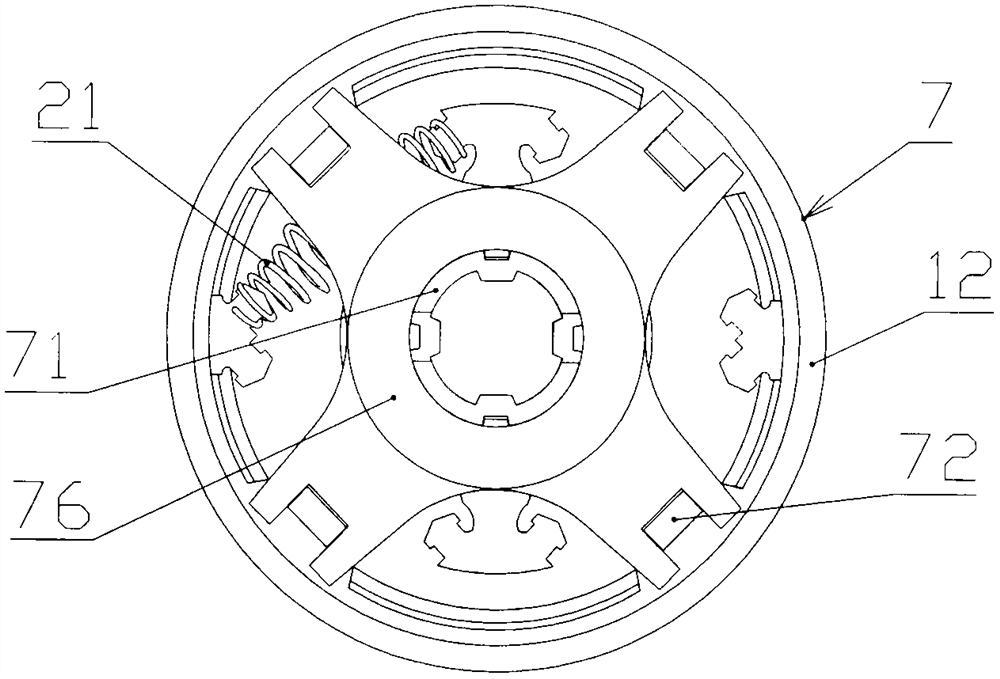

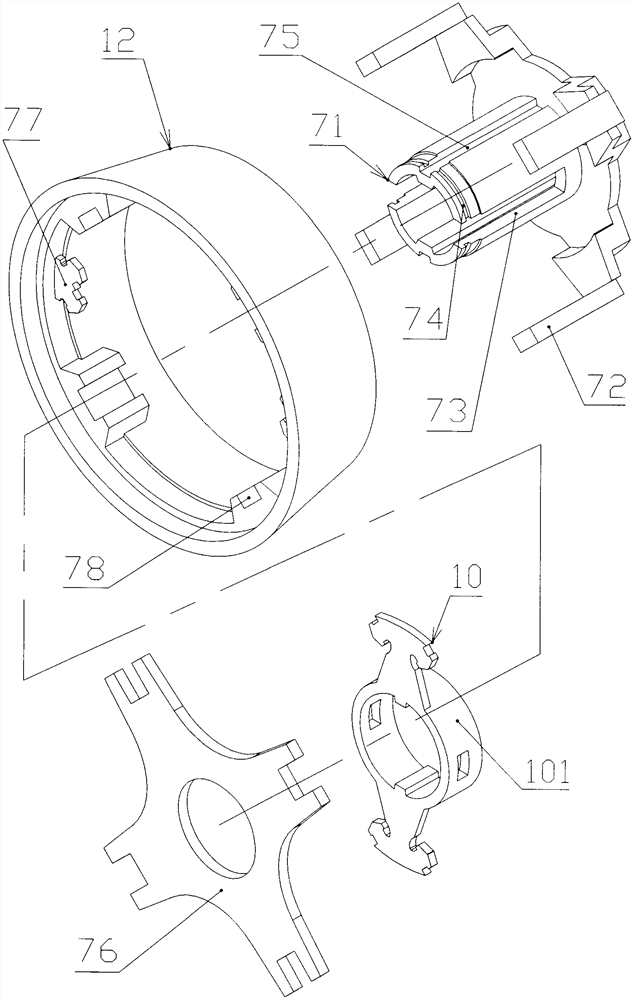

[0050] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 with Figure 15 shown. figure 1 It is an embodiment of the automatic transmission of the present invention that surpasses the shifting drive, and includes a casing encapsulating engine oil, a transmission switching system, and a gear transmission system. , the reverse action device cooperates with the one-way cone clutch 18 to realize gear shifting.

[0051] The reverse action device is a sliding claw type integrated linkage external reverse device 7. The active frame 10 assembled by the control frame and the driven frame 12 are elastically connected by the waist drum spring 21. The spring seat of the active frame 10 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com