Lightning protection device for metal chimney of boiler room

A technology of lightning protection device and boiler room, which is applied to exhaust gas device, corona discharge device, combustion product treatment and other directions, can solve the physical and chemical damage of metal chimney, damage the protective layer of metal chimney, and adversely affect the service life of chimney and other problems, to avoid physical and chemical damage, prolong service life, flexible and convenient disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

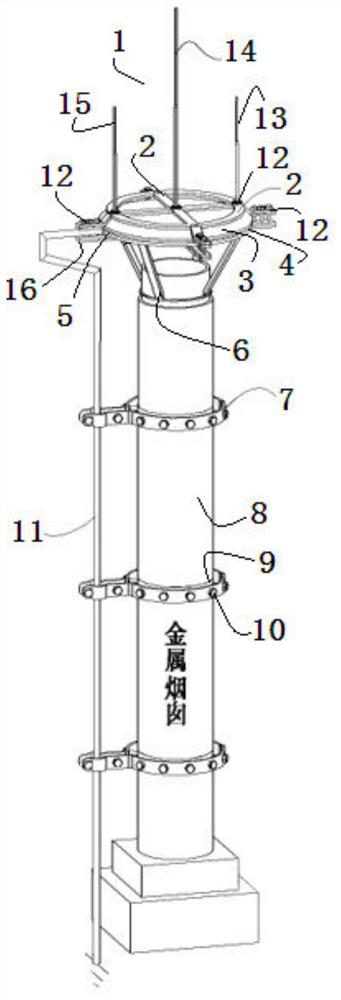

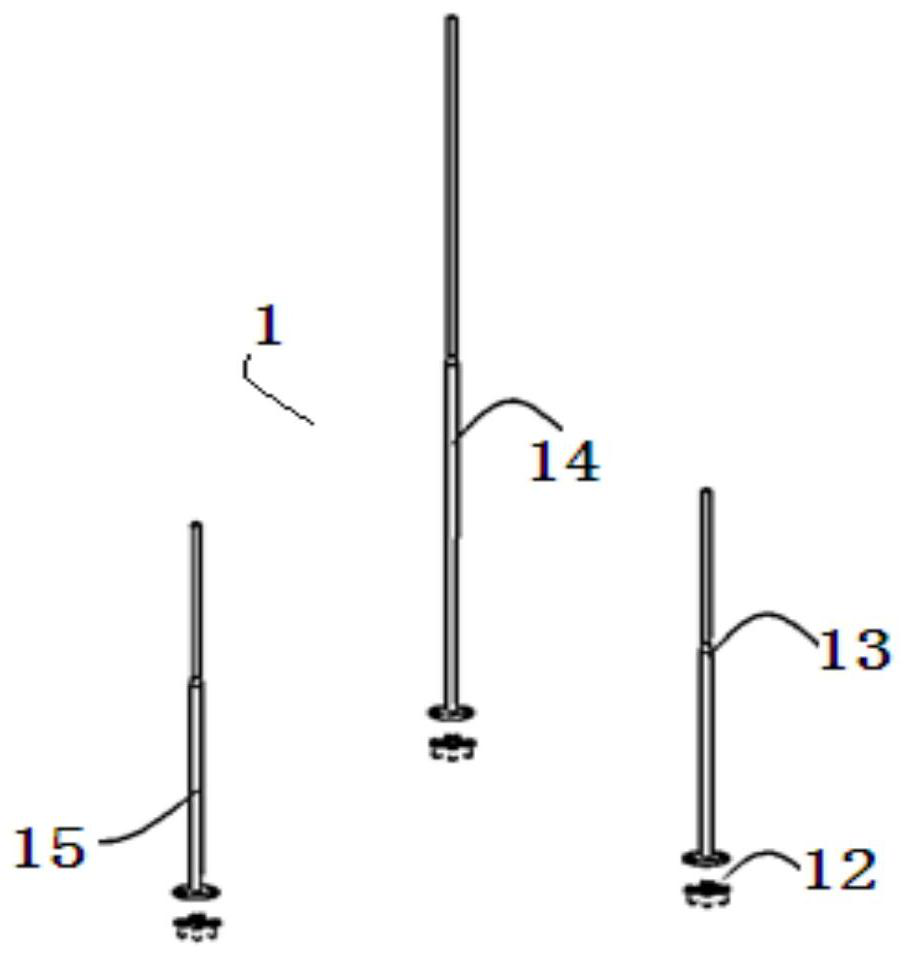

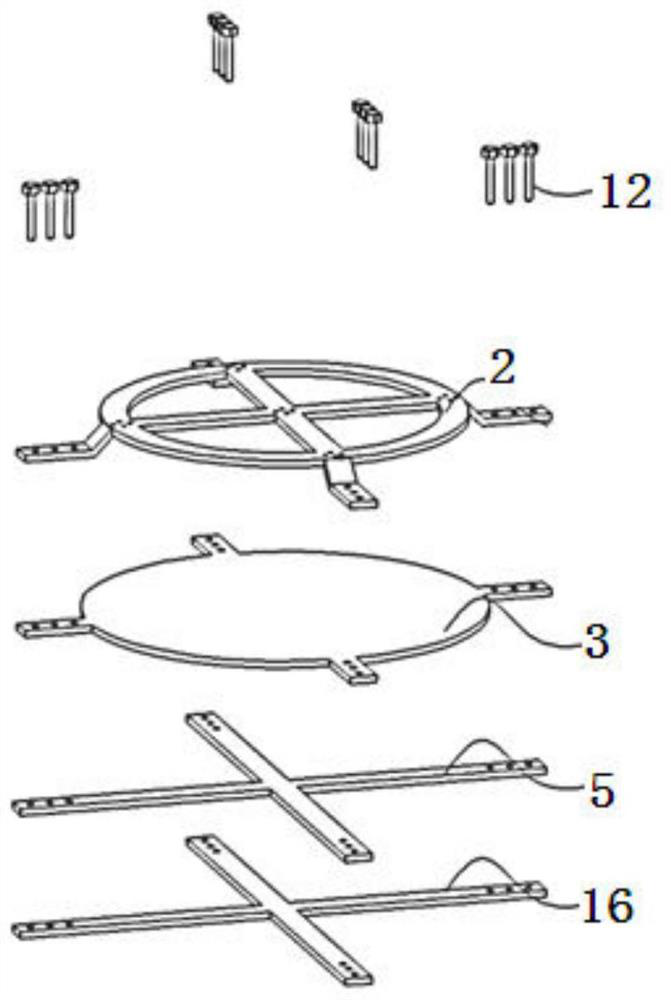

[0023] Below with the accompanying drawings ( Figure 1-Figure 5 ) to illustrate the present invention.

[0024] figure 1 It is a structural schematic diagram of a metal chimney lightning protection device for a boiler room implementing the present invention. figure 2 yes figure 1 Schematic diagram of the discrete structure of the air-termination array and its fastening bolts. figure 2 There are 4 fastening bolts at the bottom of each air receptor. image 3 yes figure 1 Schematic diagram of the discrete structure of the fixed components of the air-termination device. Figure 4 yes figure 1 Schematic diagram of the middle top structure. Figure 5 yes figure 1 Schematic diagram of the structure of the center down conductor fixing component. refer to Figure 1 to Figure 5 As shown, a lightning protection device for a metal chimney in a boiler room includes a lightning-termination fixing assembly that is insulated and connected to the chimney hood 4 , and a down-conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com